Starting Engine

General –

During break-in, it may be necessary to leave

the glow plug igniter attached to the engine to keep it run-

ning while the fuel-air mixture is adjusted “rich” for

break-in. This is normal.

The high speed needle valve adjusts the fuel-air mixture

only at higher throttle settings and will not affect low

speed. The low speed needle valve affects the fuel-air

mixture only from idle through mid-range. The idle speed

stop screw is a mechanical stop that determines only how

far the carburetor barrel will close, and has no effect on

fuel-air mixture. There must be approximately a 1mm

opening in the carburetor barrel when the carburetor is

closed (idle position). If this adjustment is not correct,

(and the engine idle speed is too slow) it will be nearly

impossible to set the low speed needle valve properly.

After priming the engine, and turning on the transmitter

and receiver, pull the engine starter handle two or three

times to circulate the fuel in the engine.

Important!

Whenever you start the engine, always pull

the starter handle with short, quick pulls straight away

from the engine. Do NOT pull the handle all the way out,

or at any angle that allows the cord to contact any part of

the engine or truck. Always let the starter handle back in

slowly after each pull, do not let go and allow the handle

to snap back into the engine. Make sure the throttle trig-

ger is set at idle speed.

Break-In procedure

Attach a fully charged 1.5 volt glow plug igniter to the

engine, and wait three seconds to allow the glow plug to

heat up. Start the engine using short, quick pulls on the

starter handle. Once the engine is running, observe the idle

speed. If the speed is too high (above 3000 RPM), open

the low speed needle valve (counterclockwise) until the

engine speed slows to a safe idle. If the engine stops or

runs too “rich” (lots of smoke and liquid fuel droplets

coming from the exhaust), then close the low speed needle

valve (clockwise) until the engine reaches a reliable idle

speed. Adjust the low speed needle valve so that the en-

gine idles as “rich” as possible while still running. If the

engine will not keep running reliably at idle speed during

this time, turn the idle speed stop screw ½ turn clockwise

to increase the minimum speed.

As soon as you are able to keep the engine running (with

the glow igniter attached if necessary) at a reliable, ultra-

rich idle, run

two full tanks

of fuel through the engine at

the rich idle setting.

If the cylinder head temperature reaches 230 degrees F,

shut down the engine, let it cool completely, and start it

again.

After idle break-in, the low speed needle valve can now be

adjusted for optimum low and mid-range running. With

Tempest Gladiator 8

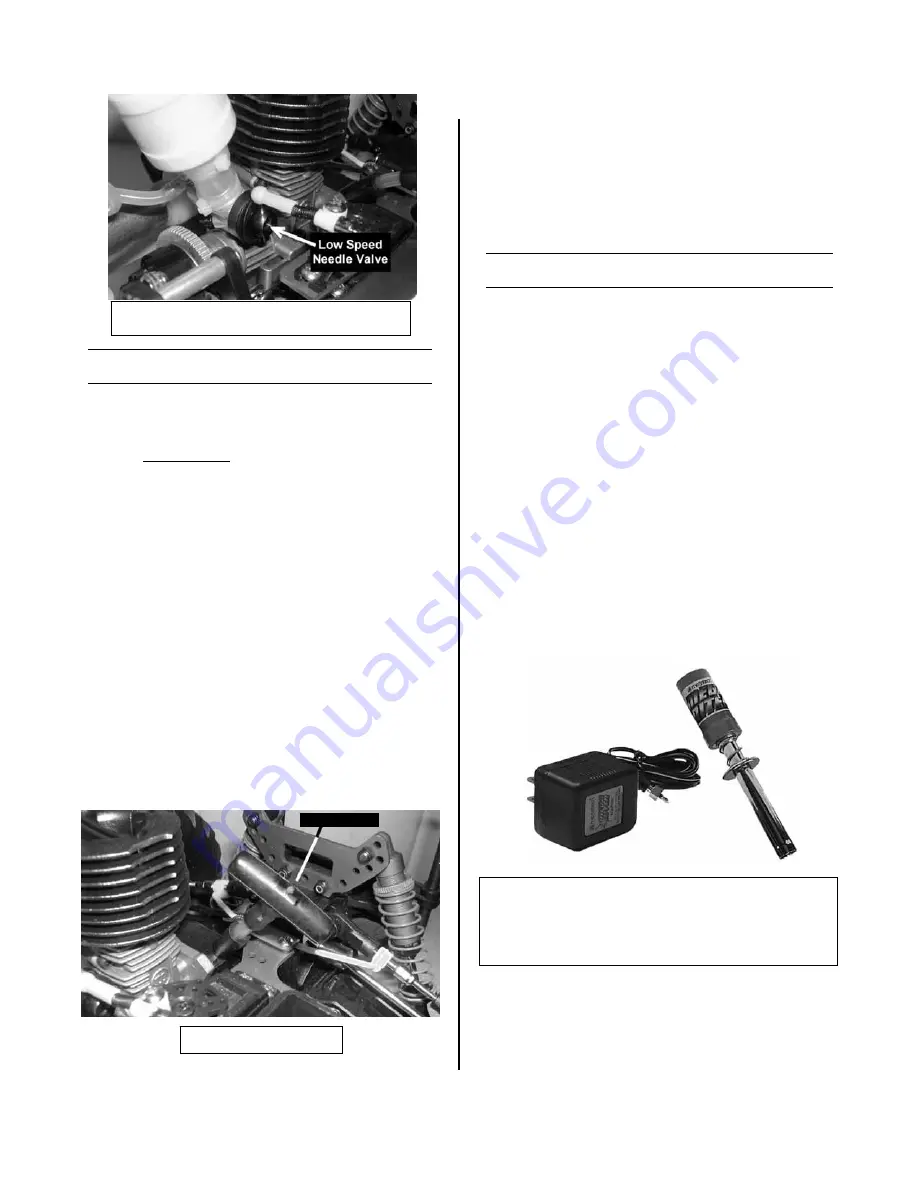

Megatech’s MegaNiter rechargeable glow

plug igniter allows easy starting, and can be

left on to keep the engine running reliably

during the rich mixture break-in period.

Location of Low Speed Needle Valve

Starter Handle

Starter Handle

Summary of Contents for MTC 7805

Page 14: ...Tempest Gladiator 14...