1-12

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

• Never use refrigerant other than R410A in an air

conditioner which designed to operate with R410A.

• Since R410A is a mixed refrigerant, any additional

refrigerant must be charged in liquid state for better

performance compared to gas state.

• POE oil is used as lubricant for R410A compressor, which

is different from the mineral oil used for R22 compressor.

During installation or servicing, extra precaution must be

taken not to expose the R410A system too long to moist air.

Residual POE oil in the piping and components can absorb

moisture from the air.

• To prevent mischarging, the diameter of the service port on

the flare valve is different from that of R22.

• Use tools and materials exclusively for refrigerant R410A.

Tools exclusively for R410A are manifold valve,

charging hose, pressure gauge, gas leak detector, flare tools,

torque wrench, vacuum pump and refrigerant

cylinder.

• As an R410A air conditioner incurs higher pressure than

R22 units, it is essential to choose the copper pipes

correctly. Never use copper pipes thinner than 0.8mm even

though they are available in the market.

• If the refrigerant gas leakage occurs during installation/

servicing, be sure to ventilate fully. If the refrigerant gas

comes into contact with fire, a poisonous gas may occur.

• When installing or removing an air conditioner, do not

allow air or moisture to remain in the refrigerant cycle.

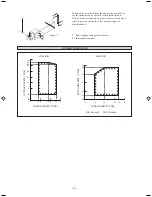

VACUUMING AND CHARGING

Purging The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with

refrigerant, the indoor unit and the refrigerant

connection pipes must be air-purged because the air

containing moisture that remains in the refrigerant cycle may

cause malfunction of the compressor.

•

Remove the caps from the valve and the service port.

•

Connect the center of the charging gauge to the vacuum

pump.

•

Connect the charging gauge to the service port of the

3-way valve.

•

Start the vacuum pump. Evacuate for approximately

30 minutes. The evacuation time varies with different

vacuum pump capacity. Confirm that the charging gauge

needle has moved towards -760mmHg.

Caution

•

If the gauge needle does not move to -760mmHg, be

sure to check for gas leaks (using the refrigerant

detector) at flare type connection of the indoor and

outdoor unit and repair the leak before proceeding to

the next step.

•

Close the valve of the changing gauge and stop the vacuum

pump.

•

On the outdoor unit, open the suction valve and liquid

valve (in anti-clockwise direction) with 4mm key for

hexagon sacked screw.

Charge Operation

This operation must be done by using a gas cylinder and a

precise weighing machine. The additional charge is

topped-up into the outdoor unit using the suction valve via

the service port.

•

Remove the service port cap.

•

Connect the low pressure side of the charging gauge to

the suction service port center of the cylinder tank and

close the high pressure side of the gauge. Purge the air

from the service hose.

•

Start the air conditioner unit.

•

Open the gas cylinder and low pressure charging valve.

•

When the required refrigerant quantity is pumped into the

unit, close the low pressure side and the gas cylinder valve.

•

Disconnect the service hose from service port. Put back

the service port cap.

Liquid Side

Indoor Unit

Outdoor Unit

Gas Side

Low

Hi

Vacuum

Pump

Open

Close

Close

Close

Discharge Valve

Suction Valve

Suction Valve

Discharge Valve

Liquid Side

Indoor Unit

Outdoor Unit

Gas Side

Low

Hi

Open

Close

Open

Open

Check

Valve

Service Port

Outdoor Unit 3 Ways Valve

Flare Nut

Refrigerant Piping

Allen Key

1 IM-5CEYER-1009(0)-EN

2/11/10, 4:29 PM

12