SYSTEM OPERATION

16

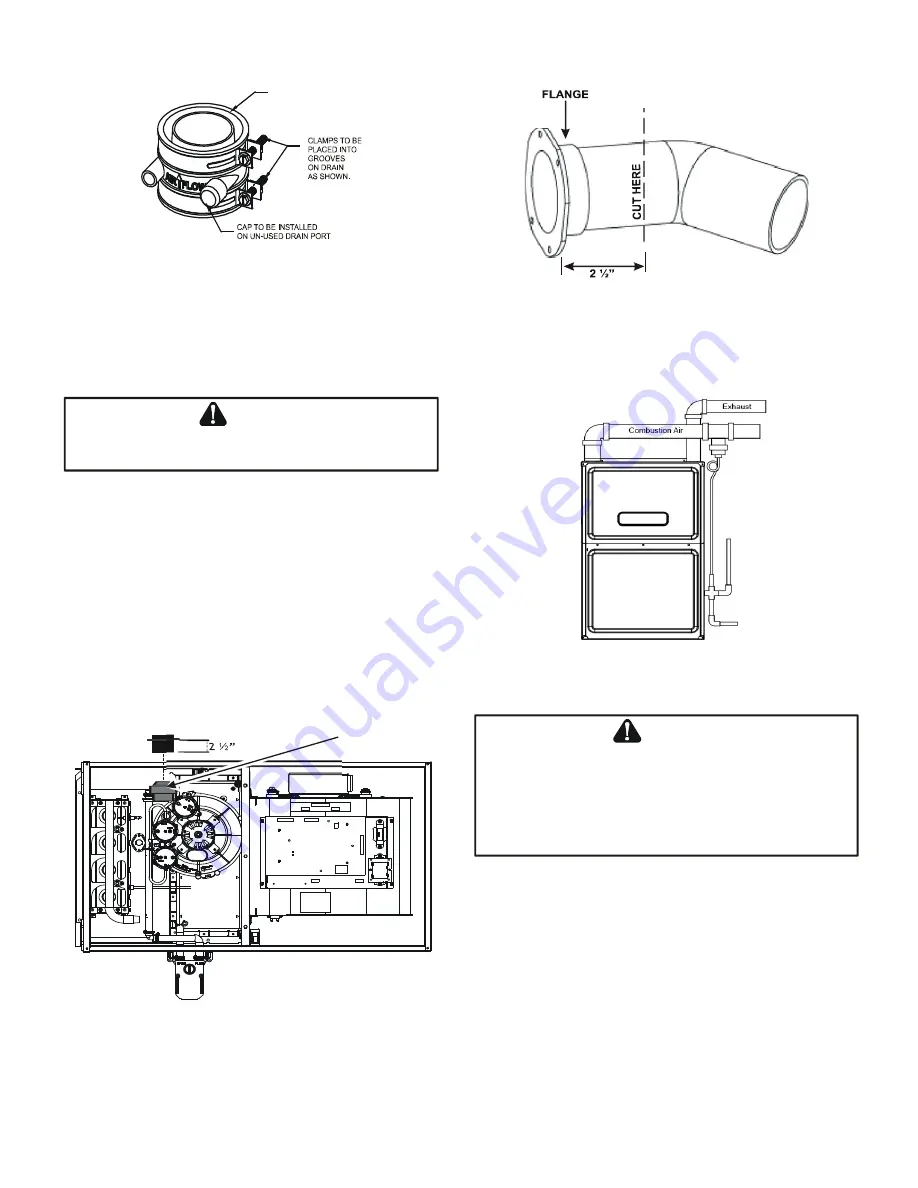

VENT-DRAIN

Figure 8

NOTE:

For

non-direct vent

installations, a minimum of one

90° elbow should be installed on the combustion air intake

coupling to guard against inadvertent blockage.

COMBUSTION AIR PIPE

Direct Vent Installations

E

DGES

OF

SHEET

METAL

HOLES

MAY

BE

SHARP

. U

SE

GLOVES

AS

A

PRECAUTION

WHEN

REMOVING

HOLE

PLUGS

.

WARNING

On

upflow

units secure the combustion air intake pipe to

the air intake coupling by using a take apart rubber coupling

supplied with the furnace or a plastic coupling. Also, the in

-

take coupling may be inverted to allow the intake pipe to be

glued directly to it. After inverting the coupling, secure it to

the furnace top with screws. On

counterflow

units secure the

combustion air intake pipe to the air intake coupling using the

rubber coupling and worm gear hose clamps provided with the

unit. The counterflow rubber coupling allows service removal

of air intake piping internal to the furnace blower compartment.

The combustion air intake pipe can also be secured directly

to the counterflow unit air intake pipe coupling.

Insert flange. Cut 2 ½” long.

Figure 9

RF000142

Figure 10

Figure 9B

T

HE

RUBBER

ELBOW

IS

NOT

DESIGNED

TO

SUPPORT

A

LOAD

. W

HEN

THE

RUBBER

ELBOW

IS

MOUNTED

EXTERNALLY

TO

THE

FURNACE

CABINET

,

EXTREME

CARE

MUST

BE

TAKEN

TO

ADEQUATELY

SUPPORT

FIELD

-

SUPPLIED

VENT

/

FLUE

PIPING

,

AS

DAMAGE

CAN

RESULT

IN

LEAKS

CAUSING

BODILY

INJURY

OR

DEATH

DUE

TO

EXPOSURE

TO

FLUE

GASES

,

INCLUDING

CARBON

MONOXIDE

WARNING

COMBUSTION AIR INTAKE OPTIONS:

The RF000142 cou

-

pling can be secured directly to the furnace intake coupling

if condensation is a concern. If the RF000142 is used on the

combustion air inlet, it must be installed with the arrow point

-

ing up. It should be noted, the combustion air will actually be

moving in a direction opposite of the arrow on the RF000142

coupling. It must have a field supplied, trapped drain tube

free-draining to proper condensate disposal location. A loop

in the drain tube can serve as a trap. The unused RF000142

drain fitting should be capped. A tee installed in the intake

pipe is also an acceptable method of catching condensation.

It must have a field supplied, trapped drain tube or pipe,

free-draining to proper condensate disposal location. A loop

in the drain tube can serve as a trap. (See Figure 9B)