Summary of Contents for GPSLR Series

Page 2: ......

Page 5: ...5 THIS PAGE INTENTIONALLY LEFT BLANK ...

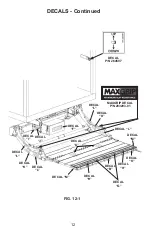

Page 13: ...13 DECAL SHEET P N 267432 01 FIG 13 1 ...

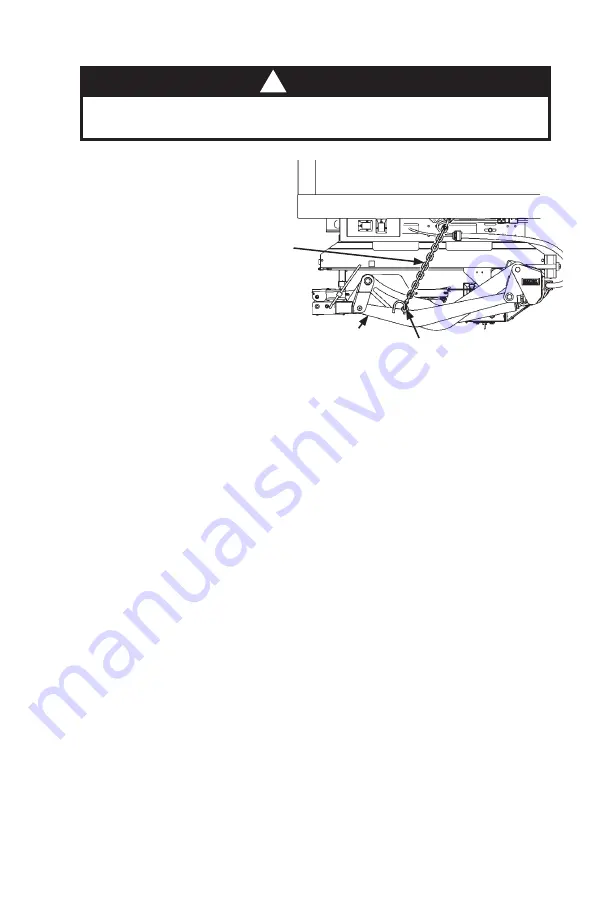

Page 14: ...14 FORKLIFT ADVISORY WARNING Keep forklift OFF of platform FIG 14 1 ...

Page 33: ......