Hi

‐

T

Centralized

controller

33

4.8

FAULT

DIAGNOSTIC

4.8.1

ACTIVE

ALARMS

You

can

view

the

current

alarms

of

the

connected

units.

To

do

this,

from

the

home

page,

press

the

triangle

icon

of

danger,

if

present;

from

here

you

can

access

to

the

list

of

all

active

alarms

in

the

system.

Also,

when

you

are

in

an

unit

page

(i.e.

Chiller

page,

see

Paragraph

3.4.1,

and

fan

coil

page,

see

Paragraph

3.4.2),

by

pressing

the

triangle

that

appears

on

the

machine,

you

go

to

a

menu

where

you

can

see

current

alarms

of

the

selected

machine.

4.8.2

ALARM

HISTORY

The

keyboard

manages

a

detected

alarms

list

for

all

the

plant

that

shows

the

date

and

time

of

the

alarm,

the

affected

machine

and

alarm

type.

In

the

historic

are

stored

up

to

100

alarms,

once

exceeded

the

limit,

it

automatically

deletes

the

older

alarms.

To

go

to

the

alarm

history:

from

the

system

main

page,

go

into

"

Configuration

"

‐

>

"

Service

menu

"

‐

>

"

Alarm

list

".

Having

maintainer

password,

you

can

set

that

the

alarm

history

is

also

accessible

from

the

user

menu;

to

do

this

go

into

"C

onfiguration

"

‐

>

"

Service

menu

"

‐

>

"

Parameters

"

‐

>

"K

eyboar

d"

‐

>

Par

33/44:

Enable

user

alarm

log

=

1

.

4.9

DOUBLE

SET

‐

POINT

AND

DEHUMIDIFICATION

FUNCTIONS

The

double

set

‐

point

function

introduces

a

second

plant

side

set

‐

point

(both

in

cooling

mode

and

in

heating

mode).

The

application

field

is

primarily

that

of

the

floor

cooling

assisted

by

fan

coil

for

dehumidification.

The

purpose

of

the

application

is

to

prevent

in

any

condition

the

formation

of

condensation

on

the

floor,

and

in

any

case

to

ensure

the

welfare

thermo

hygrometric.

The

activation

of

the

double

set

‐

point

is

by

means

of

maintainer

parameters

(from

System

main

page

‐

>

Configuration

‐

>

Service

menu

‐

>

Parameters

‐

>

Chiller

‐

>

Chiller

name

‐

>

H82:

Enable

second

setpoint

≥

2

,

ref.

chiller

manual

for

allowable

values).

Must

also

be

set

a

digital

output

for

controlling

the

three

‐

way

valve

used

to

divert

the

flow

of

water

between

the

floor

and

fan

coils.

The

function

of

humidistat

is

instead

carried

out

directly

by

the

remote

control

Hi

‐

T,

by

means

of

its

integrated

sensors

and

the

logic

internally

implemented

related

to

the

control

of

dew

point

and

dehumidification.

Please

refer

to

the

manual

of

the

chiller

for

the

correct

setting

of

parameters

related

to

the

double

set

‐

point,

as

well

as

for

the

electrical

connections

to

be

done

in

the

terminal

board

of

the

chiller.

The

set

‐

points

can

be

set

with

double

set

‐

point

function

enabled

are:

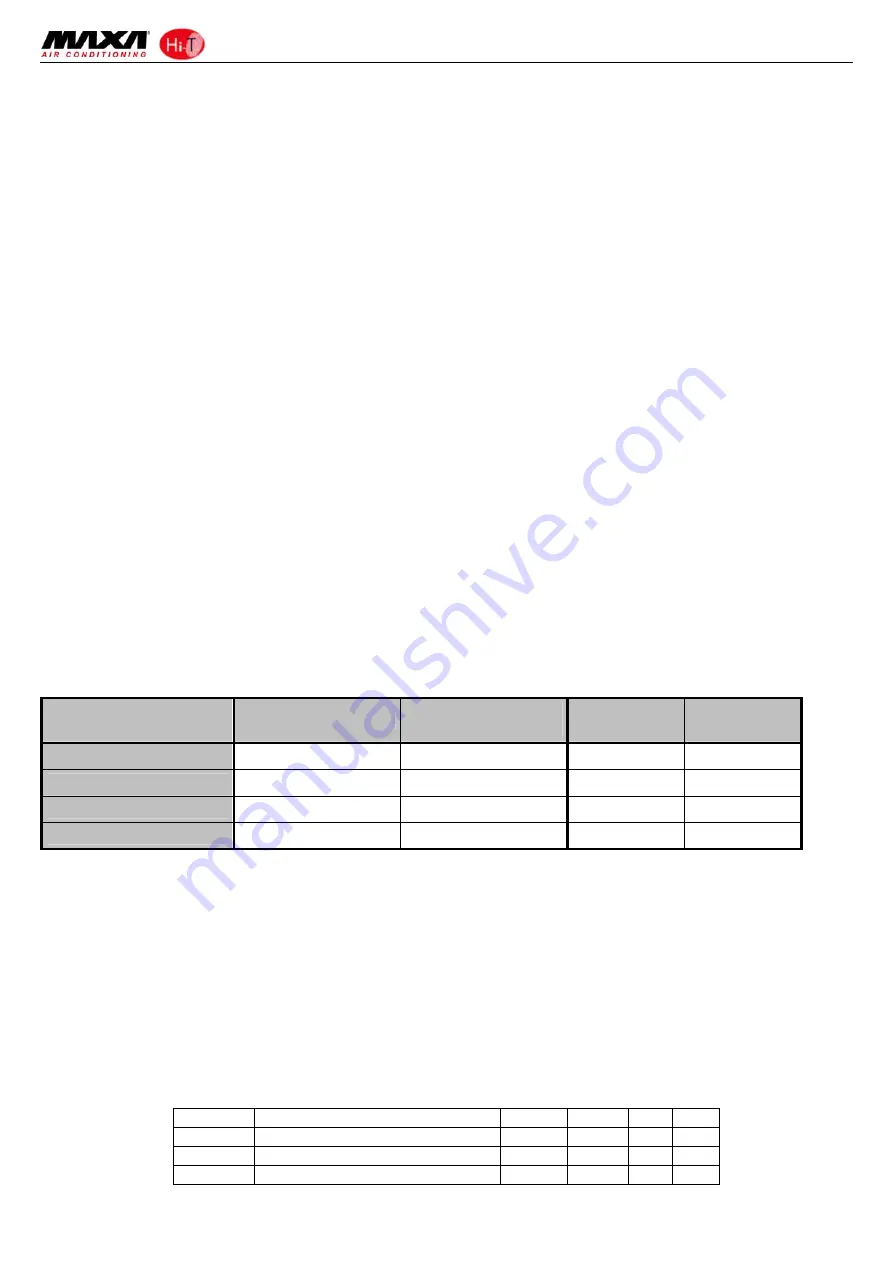

Setpoint

Setpoint

on

Hi

‐

T

Setpoint

onboard

control

panel

Summer

Winter

First

setpoint

(°C)

T

water

Coo/Hea

7

(5÷18)

45

(35÷55)

First

setpoint

eco

(°C)

T

eater

ECO

12

(5÷18)

40

(35÷55)

Second

setpoint

(°C)

T2

water

Co2/He2

18

(7÷23)

35

(25÷45)

Second

setpoint

eco

(°C)

T2

water

ECO

23

(7÷23)

30

(25÷45)

Table

6.

Set

point

settings

with

enable

double

set

point.

To

manage

the

setpoint:

•

from

Hi

‐

T

→

“

Set

‐

point

setup

”

menu

‐

>

“

Chiller

”

‐

>”

Summer

”

o

“

Winter

”

(see

Paragraph

0).

•

from

on

‐

bard

control

panel

→

SET

button.

The

second

setpoint

is

greater

than

the

first

set

point

in

summer

and

lower

in

winter:

•

in

summer:

T

2

≥

T

•

in

winter:

T

2

≤

T

The

parameters

to

be

set

for

the

management

of

dehumidification

are

accessible

from

the

maintenance

menu

(

Configuration

‐

>

Service

menu

‐

>

Parameters

‐

>

K

eyboard

):

Parameter

Name

Unit

Default

Min.

Max.

Par

42/44

Dew

‐

point

temp.

margin

°C

5.0

0.0

50.0

Par

43/44

Min.

staying

time

in

dehumidification

Seconds

300

0

600

Par

44/44

Max.

staying

time

in

dehumidification

Seconds

600

0

1200

Table

7.

Service

keyboard

parameters

for

dehumidification.

Summary of Contents for HI-T

Page 55: ......