18

WARNING:

When servicing, use only Mastercraft

®

replacement parts. The use of

any other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this tool may create a safety hazard

unless repairs are performed by a qualified technician. For more information, call the Toll-

free Helpline, at 1-800-689-9928.

Always order by PART NUMBER, not by key number.

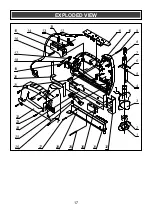

Key #

Part #

Part Name

Quantity

1

J105-01

Dampening cup

1

2

J105-02

Dampening pad

1

3

J105-03

Loop

1

4

J105-04

Striking plate

1

5

J105-05

Pin

1

6

J105-06

Pin

1

7

J105-07

Solenoid core

1

8

J105-08

Tension spring

1

9

J105-09

Pin

1

10

J105-10

Left housing

1

11

J105-11

PCB

1

12

J105-12

Cord & plug

1

13

J105-13

Locking tab

1

14

J105-14

Twisted reed

1

15

J105-15

Switch trigger

1

16

J105-16

Pin

1

17

J105-17

Cord clamp

1

18

J105-18

Screw

2

19

J105-19

Switch

1

20

J105-20

Safety arm

1

21

J105-21

Steel hoop

1

22

J105-22

Right housing

1

23

J105-23

Screw

7

24

J105-24

Outer magazine channel

1

25

J105-25

Magazine lock

1

26

J105-26

Spring

1

27

J105-27

Pin

1

28

J105-28

Inner magazine channel

1

29

J105-29

Pin

1

30

J105-30

Nail pusher

1

31

J105-31

Nail pusher spring

1

32

J105-32

Nail channel

1

33

J105-33

Switch trigger spring

1

PARTS LIST

!