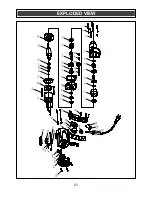

23

Key #

Part #

Part Name

Quantity

27

2030110019

Pendulum plate

1

28

3150010071

Fan

1

29

1010180003

Rotor assembly

1

30

4010010060

Bearing 608-2RS

1

31

3140040001

Bearing Sleeve

1

32

2010170017

Magnetism ring

1

33

4100050004

Pendulum plate

1

34

3150050046

Baffle plate - rear

1

35

3150160134

Baffle plate mount

1

36

4030010122

Self tapping screw ST3.9X70

2

37

1020180003

Stator

1

38

2050060140

Electric ring

2

39

3011180003

Housing

1

40

4030010019

Self tapping screw ST2.9X4

1

41

1130040031

Digital PCB

1

42

4030010020

Self tapping screw ST2.9X6

1

43

3160070009

Transparent cover

1

44

3110010137

Decorative plate

1

45

3120020095

Digital button "+"

1

46

3120020096

Digital button "

–"

1

47

3120020097

Digital button "I/0"

1

48

1230010066

Brush holder

2

49

3150150019

Carbon brush

2

50

3150140018

Carbon brush cap

2

51

3160010043

Back cover

1

52

4030010105

Self tapping screw ST3.9X20

4

53

1062020029

Switch assembly

1

54

2010170019

Magnetic column

1

55

3120010049

Switch button

1

56

3120070072

Front handle

1

57

4030010106

Self tapping screw ST3.9X20

3

58

1250010002

Terminal block

1

59

4030010099

Self tapping screw ST3.9X14

2

60

2030050002

Cord clamp

1

61

1190040004

Cord

1

62

3140010004

Cord guard

1

PARTS LIST

Summary of Contents for 054-1265-6

Page 21: ...21 EXPLODED VIEW...