Filling with gearbox oil

CAUTION

Product damage!

The product is supplied without gearbox oil.

Make sure it is filled with gearbox oil before using for the first time.

Operating the gearbox with insufficient oil will damage the gearbox.

Contaminated gearbox oil will reduce the service life of the gearbox.

Use the specified gearbox oil.

– Switch off the motor.

– Disconnect the spark plug.

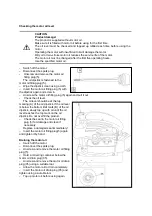

– Unscrew and remove the gearbox oil filling

plug (36) using a suitable tool.

– Carefully top up the gearbox oil. Do not

spill!

– Re-tighten the gearbox oil filling plug (36).

Operation

Check before starting!

WARNING

Risk of injury!

The product must only be put into operation if no defects are found. Ensure that

any defective parts are replaced before the product is used again.

CAUTION

Product damage!

The product is supplied without motor oil.

Make sure it is filled with motor oil before using for the first time.

The oil level must be checked and topped up refilled each time before using the

motor.

Operating the motor with insufficient oil will damage the motor.

Dirty oil or two-stroke motor oil reduces the service life of the motor.

The motor oil must be changed after the first five operating hours.

Use the specified motor oil.

CAUTION

Product damage!

The product is supplied without gearbox oil.

Make sure it is filled with gearbox oil before using for the first time.

Operating the gearbox with insufficient oil will damage the gearbox.

Contaminated gearbox oil will reduce the service life of the gearbox.

Use the specified gearbox oil.