14

6.2.3 Flue Inspection & Cleaning

Flue system should be checked and if needed be swept by a professional chimney sweep at least once a year

depending upon usage. Do not use chemical chimney cleaners. Check the flue sections nearest the firebox. If a

flue system is becoming excessively blocked or needs frequent cleaning, investigate the installation, fuel, and

operation of the burner with help of a professional.

4. Remove the injectors, ceramic block and boards from the bottom combustion chamber and keep them in

a safe place as per instruction in 6.2.3.

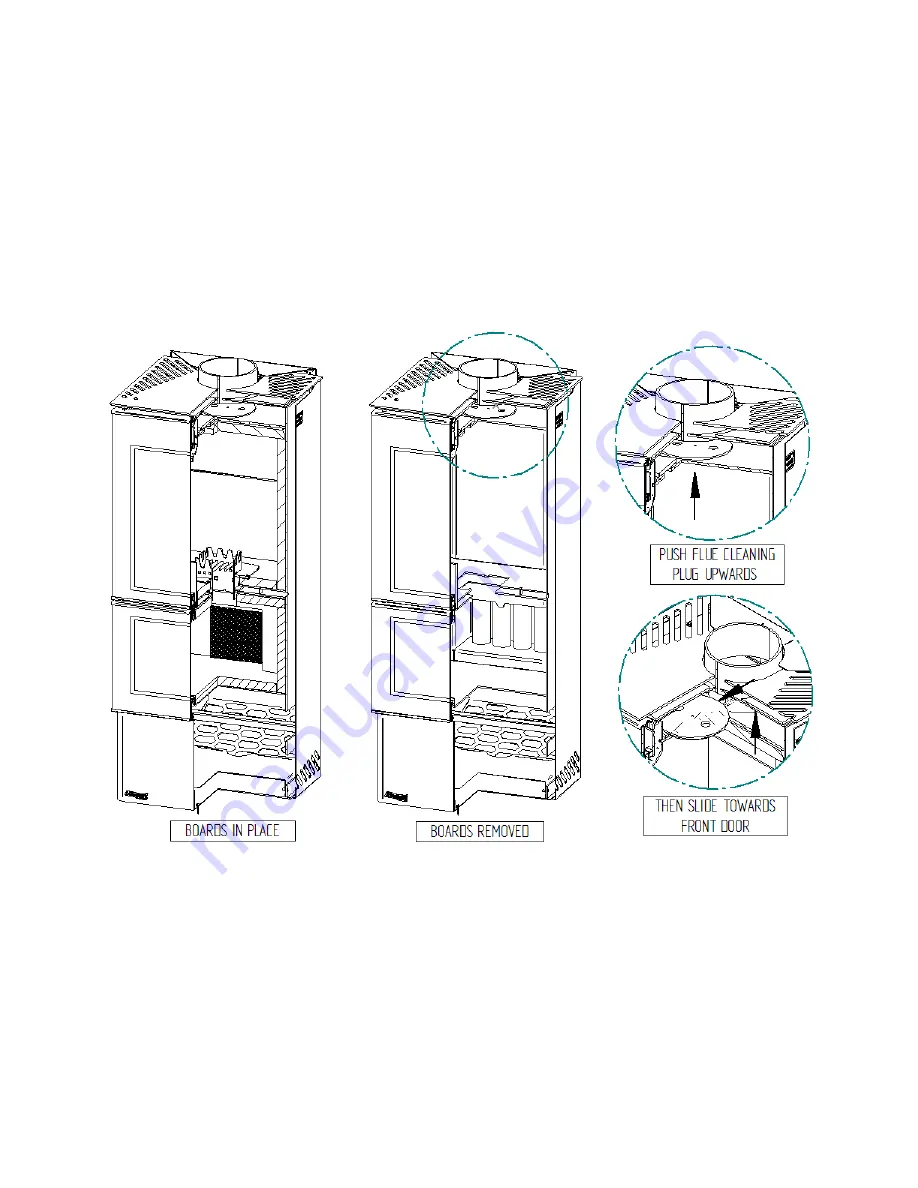

5. Fig 6.2 shows the location of flue cleaning plug situated inside the top exhaust chamber which is above the

top baffle board.

6. Push this plug upwards to release from the steel plate and then slide it towards the front of the firebox.

7. This will enable to drop and collect all the chimney dirt into bottom combustion chamber without removing

the main flue pipe.

8. Once chimney sweep operation is complete, clean the top exhaust chamber properly and pull the flue

cleaning plug back in place. Ensure that it seals the circular cutout correctly.

Fig 6.2

6.2.4 Cleaning the Heat Exchanger

Though the ceramic block arrests most of the fly ash, some fine ash particles will enter heat exchanger and

condense as soot over the period.

9. Carry out this procedure after completing procedures given in 6.2.2 and 6.2.3.

10. Close the bottom combustion chamber door

11. Remove the rear access panel

12. Remove the heat exchanger cover plate (Refer Fig 6.3)

13. Insert a long wire brush through this opening to clean the outer surface of all the tubes

14. All the ash will fall at the base of the heat exchanger.

15. Open the bottom combustion chamber door to remove the ash

16. Screw back the heat exchanger cover plate and the rear access panel once both chambers are cleaned.