11

11

Instructions EM39003 - 05/10

39003 Series High Performance butterfly Valves

ANSI Class 600 3" – 14"

Lug Valves

Wafer

Valves

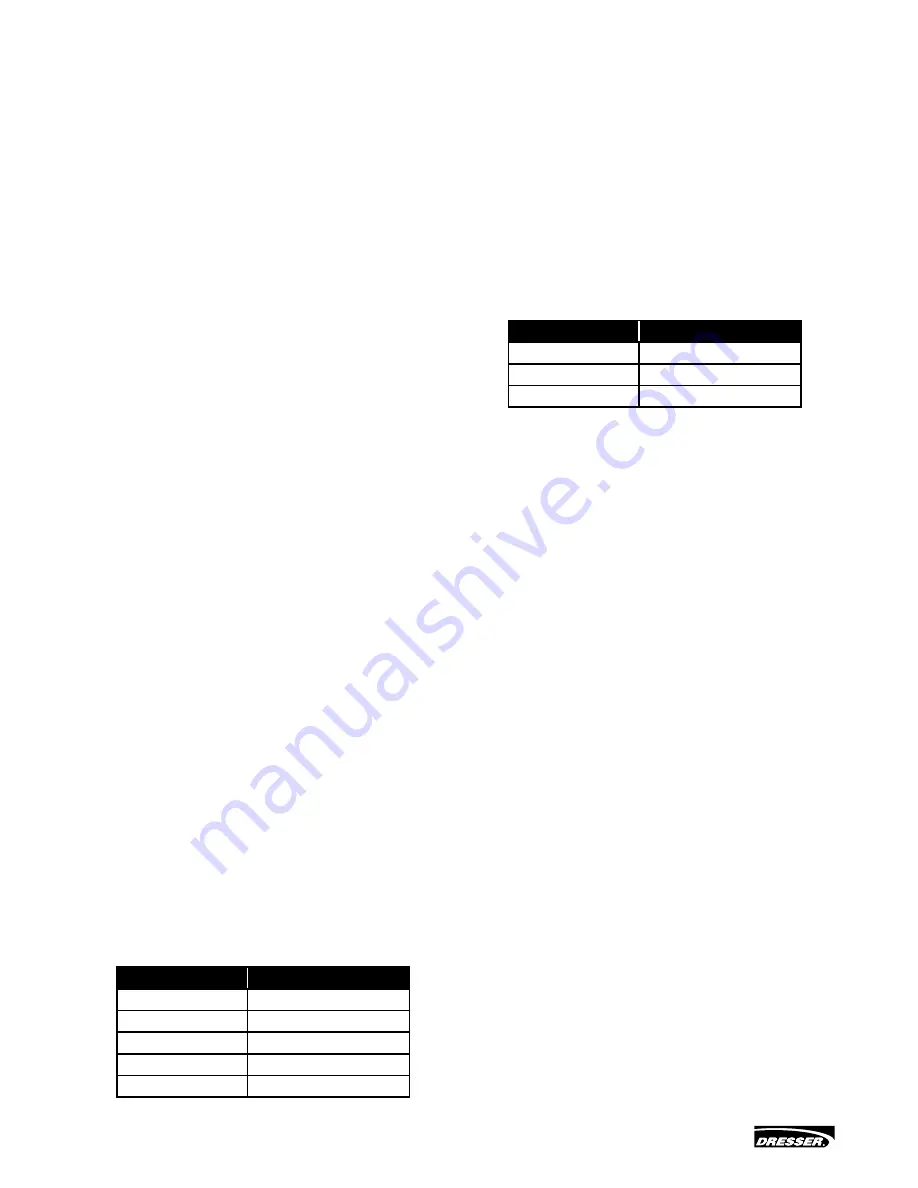

Bolt Engagement in Valve*

Studs & Nuts

Machine Bolts

Studs & Nuts

Valve

Size

Valve

Series

Thread

Size

Qty

A

Length

A

Qty

B

Length

B

Qty

C

Length

C

Qty

D

Length

D

Qty

F

Length

F

Qty

G

Length

G

Qty

E

Length

E

3"

g

¾-10

8

1.034

8

1.026

8

3.50

8

3.50

8

2.25

8

2.38

8

7.00

4"

g

7

/

8

-9

8

1.274

8

1.165

8

3.50

8

3.25

8

2.75

8

2.75

8

7.75

6"

g

1-8

12

1.274

12

1.306

12

4.75

12

4.75

12

3.25

12

3.25

12

9.50

8"

g

1

1

/

8

-8

12

1.794

12

1.795

12

5.75

12

5.75

12

4.12

12

4.12

12

11.50

10"

H

1¼-8

12

2.495

12

2.000

12

6.75

12

6.25

12

5.00

12

4.50

12

13.00

H

1¼-8 4**

1.375

4**

2.000

4**

5.50

4**

6.25

4**

3.88

4**

4.50

8**

6.25

12"

H

1¼-8

16

2.683

16

2.697

16

7.00

16

7.00

16

5.38

16

5.38

16

14.00

H

1¼-8

4**

1.325

4**

1.765

4**

5.25

4**

6.00

4**

4.00

4**

4.38

8**

6.00

14"

H

1

3

/

8

-8

16

2.994

16

2.996

16

7.50

16

7.50

16

CF

16

CF

16

15.00

H

1

3

/

8

-8

4**

1.506

4**

1.869

4**

6.00

4**

6.50

4**

CF

4**

CF

8**

6.50

Maintenance Instructions

3.1 Safety Precautions

before removing the valve from the line or loosening any bolts,

it is important to verify the following conditions:

1.

be sure the line is depressurized and drained.

2.

be sure of the pipeline media. Proper care should be taken

for protection against toxic and/or flammable fluids.

3.

never install the valve without an Operator (Manual or

Automatic) already attached to the valve shaft.

4.

never remove the Operator from the valve while the valve is in

the pipeline under pressure. The eccentric valve design may

allow line pressure to open the valve if the handle/actuator is

not in place while the valve is under pressure.

5.

Always be sure that the disc is in the full closed position

before removing or installing the valve.

6.

Take care in handling the valve. Personal injury or property

damage may result if the valve is damaged or mishandled

during maintenance operations.

3.2 General Maintenance

normal maintenance for a Masoneilan HPbV is limited to

adjustment of the shaft packing by tightening down evenly

on the gland flange using the gland flange studs and nuts.

Overtightening of the gland should be avoided since this will

shorten the life of the packing. During commissioning, it is

common for dirt and foreign objects to be left in the pipeline

during construction. This debris can damage the HPbV seat or

disc edge which will prevent the valve from providing tight shut-

off. In such cases seat replacement may be necessary.

3.3 Packing Replacement

1.

Remove the handle or actuator and the mounting hardware

from the valve.

2.

Remove the gland flange nuts and lockwashers.

3.

Remove the gland flange and gland.

4.

Replace the old packing with new packing. Correct

packing selection is important. On larger valves it may be

necessary to compress each stem seal into the stuffing box

before adding the next one.

5.

Reinstall gland, gland flange, lockwashers and nuts.

6.

Tighten the gland flange nuts evenly to torque specified in

Table 1.

7.

Operate the disc several times.

8.

Reinstall the handle or actuator and mounting hardware.

9.

Set the actuator stops.

Table 1

Valve Size (in.)

Torque (in.-lb.)

2 to 8

25

10 to 12

35

14 to 20

50

24 to 30

75

36 to 48

100

3.4 End Cap Seal Replacement

(where applicable)

1.

Remove the end cap bolts and lockwashers.

2.

Rotate the end cap to break the seal, then pull the cap out.

3.

Remove the old seal.

4.

Clean the body and end cap prior to installing the new seal.

5.

Slide the new seal into place, then guide the end cap into

the body.

6.

Align the bolt holes and reinstall the lockwashers and bolts.

7.

Tighten the bolts evenly to the torque specified in Table 2.

Table 2

Valve Size (in.)

Torque (in.-lb.)

2 to 8

50

10 to 12

80

14 to 30

100

3.5 Standard Soft Seat Replacement

1.

Place the valve on a bench with the seat retainer facing up.

Use blocks to elevate the valve above the work surface to

provide enough clearance to prevent the disc from being

damaged when the valve is opened.

2. A. Cap Screw Retainer:

Remove the cap screws and lift the seat retainer out of

the valve.

B. Wedge Ring Retainer:

Unlock the retainer by removing the set screws. If

difficulty is experienced in removing the retainer, open

the disc approximately 20 degrees and then tap the

retainer with a non metallic hammer. Lift the retainer

from the body.

3.

Remove the old seat from the seat retainer and discard.

4.

Thoroughly clean the seat cavity in the body and the seat

retainer prior to installing a new seat.

5.

Carefully clean and polish the disc sealing surface with a

soft cloth. The disc sealing surface should be free of all

grooves and scratches.

6.

Place the seat retainer on a flat surface with the seat

locating area facing up.

7.

Place the new preformed seat assembly (Seat and O-ring)

on the seat retainer with the marked (tape) side facing

down.

8.

Using the balls of each thumb, press down on the seat

engaging the shoulder of the seat behind the lip in the

seat retainer. Stretch the seat into place by sliding each

thumb around the circumference of the seat maintaining

downward pressure and forcing the seat shoulder over the

seat retainer lip.