Doc.Ref.No.:mVMT/om/101

masibus

Issue No. :00

Model : VM908

Operator’s Manual VM-908 Vibration meter

Page 7 of 11

02/05/16

For instance, a machine supported by rubber or springs often

have resonance’s at low running speeds. The machine starts

vibrate at certain low rpm. When the speed is increased

above these resonance frequencies the vibration is reduced.

This machine is considered flexible.

A resonance can easily be found when a flexible machine is

running up or down in speed. The resonance’s are located at

the rpm’s where the vibration have a local maximum level.

Modern machines have high rpm and flexible bearing-

supports and foundations and can be treated as flexible even

when it is not mounted on rubber or springs.

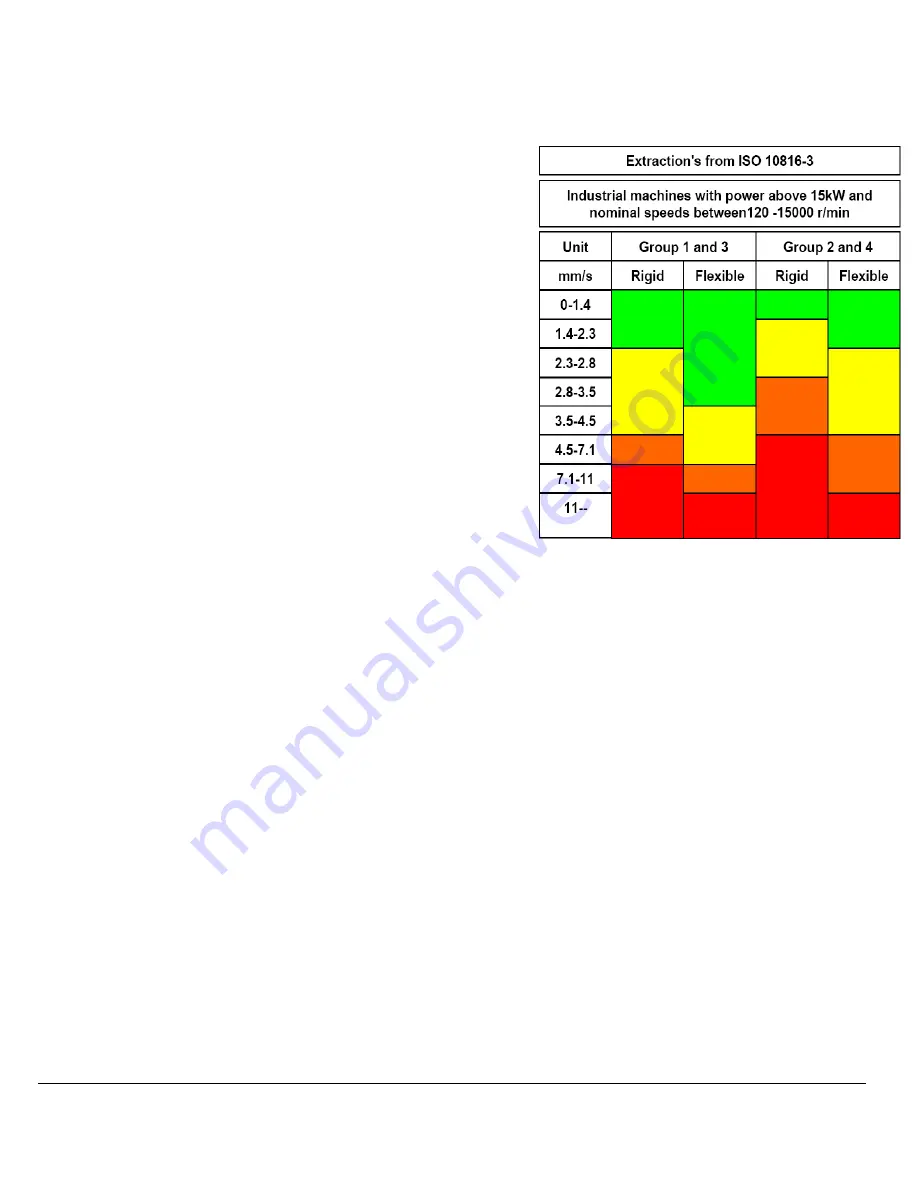

The ISO 10816-3 standard allows for slightly higher limits when a foundation is considered flexible than

when if it is rigid. A conclusion from this is also that a resonant condition in principle is not allowed or at

least should be avoided at operating speeds. In practice this also includes the double speed as well as any

other natural excitation frequency such as blade passage etc.

A great advantage with proper vibration measurements and the use of vibration standards is that you can

judge the future maintenance cost very reliably already at first start-up. If you find levels above 3 mm/s

RMS, you can be rather sure that the machine will cause increased activities in maintenance. The specific

cost and action is of course individual to the machine design.

As always when using schematic judgment like this, be very careful to use common sense in the application

of the recommendations. A certain machine is producing its specific vibration frequency pattern depending

on the transducer location and the machine properties.

The next logical step is therefore to apply filtering of the transducer signal to learn the frequency behind the

vibration and thus the exact mechanical fault. The practice of this is beyond the scope of this manual.

Looseness

By measuring the vibration on both sides of a bolt joint it is possible to find looseness in the connection.

Two machine parts joined together should have the same vibration level on both sides of the joint. Bolts

fixed in concrete foundations should have the same vibration level as the concrete if they are not loose.