VFlo Control Valves

3

PREVENTIVE MAINTENANCE

Twice yearly, operation should be checked for trouble free

performance. For the preventive maintenance, follow the steps

that are presented below:

These steps can be very well performed while the valve is in line

and, in some cases, without interrupting service. Refer to the

"Disassembly" and "Reassembly" section if an internal problem is

suspected with the valve.

Tighten flange bolting if signs of gasket leakage through the

body and line flanges are observed (See Table I for

specifications.)

Observe whether any corrosive fumes or process drippings

are damaging the valve.

Valve should be cleaned and areas of severe oxidation

painted.

Packing nuts should be tightened as necessary to prevent

Gland leakage.

CAUTION :

Over tightening of packing can cause

excessive packing wear and high shaft friction, which may

retard shaft rotation.

Where the valve is supplied with a lubricator, lubricant supply

and level needs attention. Ensure proper supply and level of

the lubricant.

Where possible, stroke valve and observe for smooth, full-

stroke operation by looking at the position indicator plate

mounted on the transfer case. An internal valve problem is

indicated by unsteady movement of the plate.

In case of a positioner being present, its calibration needs to

be checked by observing the actuator position indicator plate

and gauges. The positioner needs calibration to the correct

range.

In case an actuator is attached, the appropriate maintenance

instructions for preventive maintenance need to be referred.

Where possible, remove the air supply to observe the

actuator stroke plate for correct fail-safe action.

Ensure fastening of all valve accessories, brackets and

bolting.

The exposed portion of the valve shaft must be free from dirt

or foreign material.

I case an air filter is present, the cartridge needs to be

checked and if necessary, replacement needs to be done.

Removing Valve From Line

To remove the valve from the line, in cases where an internal

problem is suspected proceed as mentioned below:

WARNING :

Line must be depressurized to atmospheric pres-sure.

All process fluids should be drained. If caustic or hazardous materials

are present, decontaminate the valve. This is very important as it will

prevent any possible injury.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

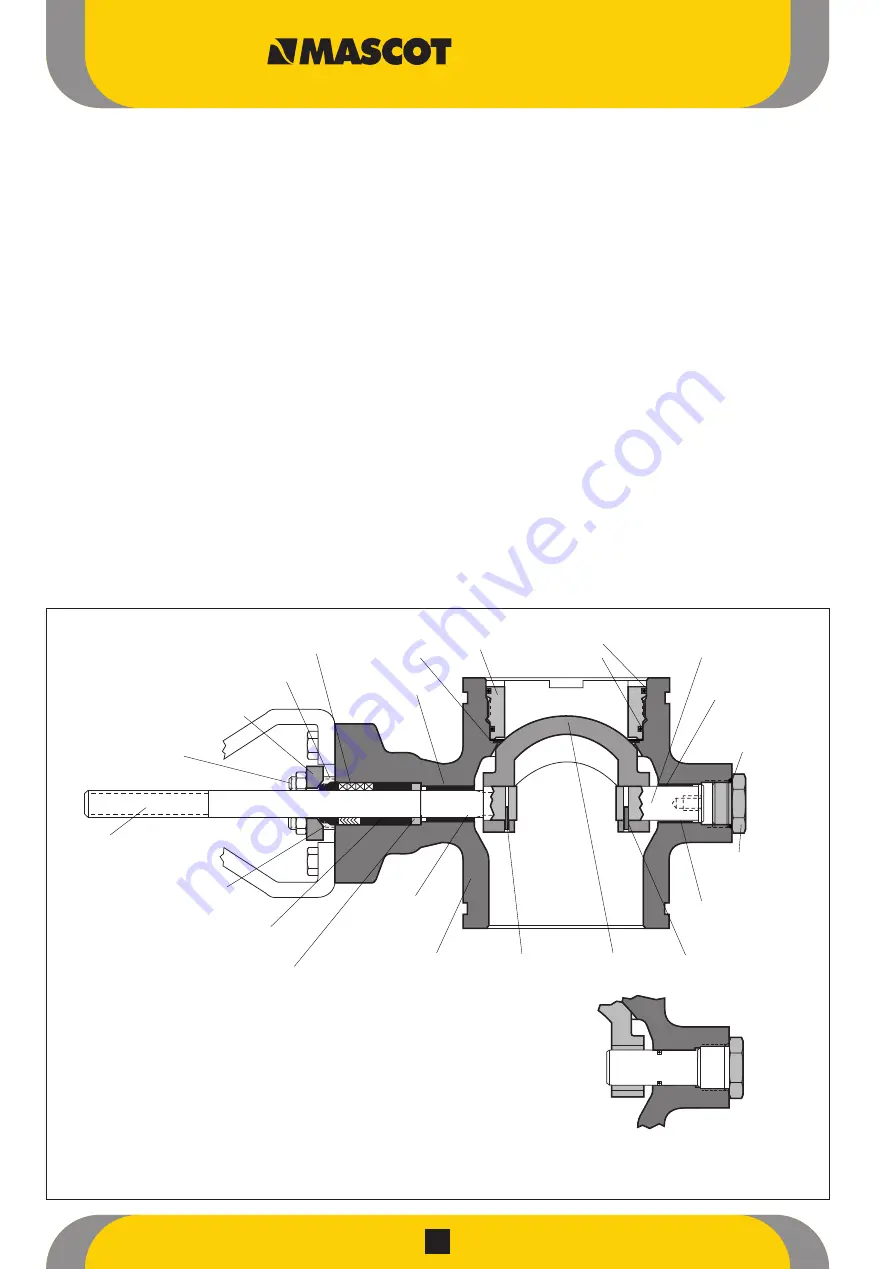

Figure 1: 3", 12" and 16" VFlo Body Assembly with Rotating Post Design

Note : Item numbers correspond to bill of material of Valve. Please refer to it for specific part numbers.

Stationary Post Design

Packing

(Item No. 88)

Packing Stud

(Item No. 109)

Gland Flange

(Item No. 80)

Packing Nut

(Item No. 117)

Shaft

(Item No. 51)

Retainer

Retainer O-rings

(Item No. 30)

(Item No. 59)

(Item No. 56)

Seals*

Shaft Bearing

(Item No. 83)

Post Bearing

(Item No. 84)

Shaft O-ring

(Item No. 62)

(optional)

O-ring

(Item No. 61)

Post

(Item No. 123)

Post O-ring

(Item No. 64)

(optional)

Plug

(Item No. 122)

Body

Shaft Pin

Ball

(Item No. 1)

(Item No. 52)

(Item No. 50)

Post Pin

(Item No. 121)

Packing Follower

(Item No. 87)

Packing Spacer

(Item No. 93)

Thrust Bearing

(Item No. 53)

(*See Figure 4 for seal configurations and item numbers.)