5

•

Maintenance Safety

WARNINGS

1. Poorly maintained equipment can become a safety hazard! In order to operate the equipment

safely and properly over a long period of time, periodic maintenance and occasional repairs are

necessary.

2. DO NOT attempt to clean or service rammer while the power supply does not cut off. Do not

open the motor cover or wash the electric device with high pressure watering instrument.

3. DO NOT launch the motor before cutting off the connection between the motor and the rammer,

because the rotary spares are exposed outside.

4.

Machine’s appearance maintenance is very important to develop its safety function. So keep the

exploded motor spares clean is especially useful to prevent motor overheating.

5. Do not leave any residual fragments in the maintenance area in case of a fire accident.

6. Replace the safety device after the maintenance was done.

7.

Make a periodic maintenance according to the manual’s instruction.

8. Replace all unreadable labels with a new MASALTA-like one. If safety labels are unreadable or

missing, that may cause deadly danger or injury.

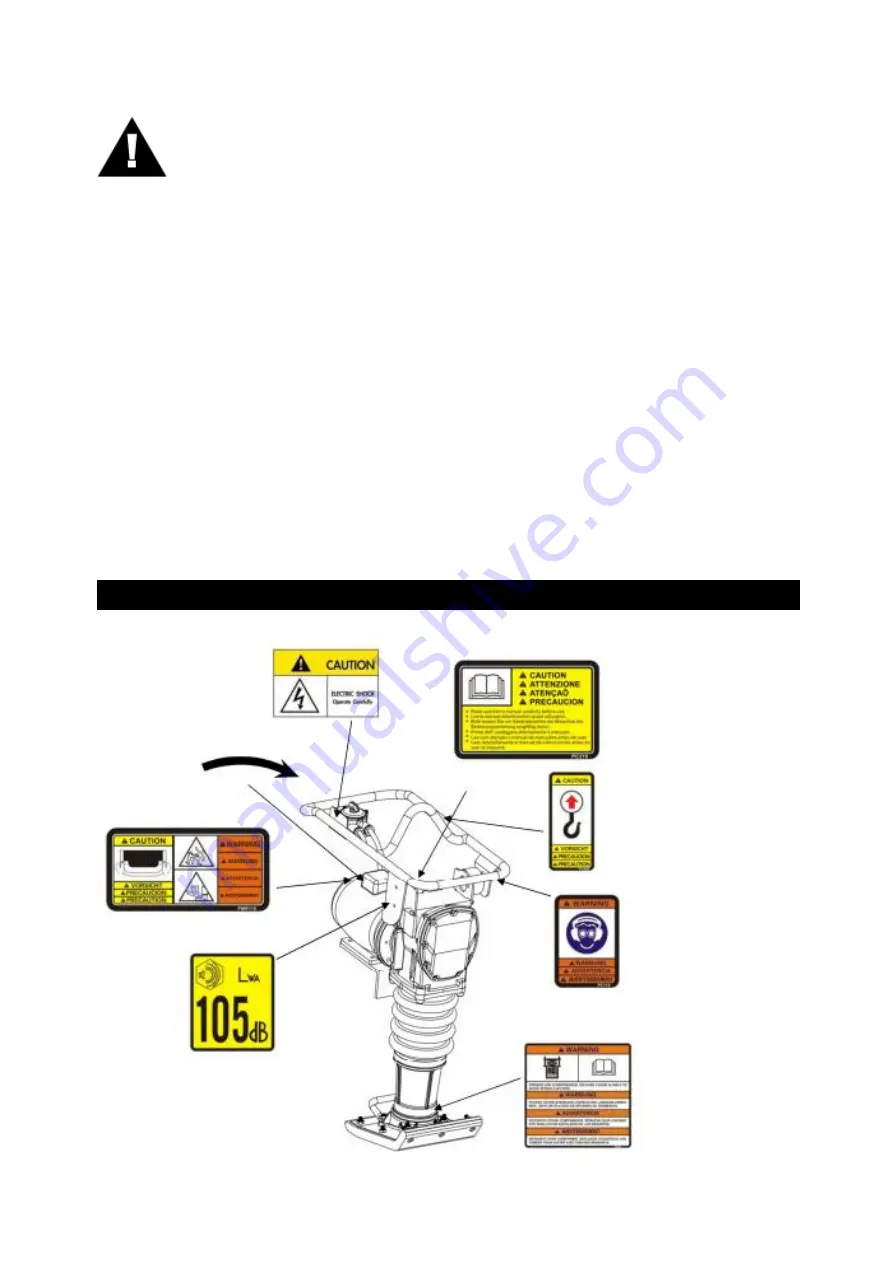

Label Location