Mas Grup

5

6. ASSEMBLY / INSTALLATION

In our standard production, the pump and the motor have been installed

vertically in a common base plate.

6.1. Location of Installation

Pump shall be installed in a location where the control and the

maintenance of the pump are easily made. The pump room shall be

suitable for operation of lifting systems such as freight elevator, forklift,

etc.

The pump group should be installed in the lowest possible location of the

pumping system in order to achieve the highest suction pressure.

6.1.1. Location of Installation- Local Ambient Temperature

When the local ambient room temperature exceeds +40

o

C in a pumping

system, suitable ventilation should be provided in order to remove the

heat dissipated to the environment and supply fresh air.

6.2. Type of Connection

Type of connection depends on the design type and the size of the pump

and the motor, as well as the local installation conditions. Foot-mounted

vertical pump-motor units have been installed in a common base plate.

6.3. Piping

6.3.1. General

Do not use the pump as the hinged support for the piping system.

Put enough supports under the piping system in order to carry the

weight of the pipe and fittings.

Avoid piping system loads on pump by installing flexible components

(compensator) to suction and discharge of the pump.

By mounting flexible supporting items, take into consideration the fact

that these items may elongate under the pressure.

Suction pipe shall be in a constantly increasing slope to the pump. Air in

the suction pipe shall be arranged to move into the pump

Discharge piping shall be in a constantly increasing slope to the

reservoir or discharge point, without up and downs which can cause air

pockets in the piping system. At locations where forming of air pockets

is possible, special items like air valve and air cock are mounted to

evacuate the trapped air.

It is important that pipe diameter and fittings are at least as much as the

pump opening diameter or preferable one or two size higher. One

should never use fittings with smaller diameters than the pump exit

diameter. In particular, preferred fittings like foot valve, strainer, filter,

check valves and valves shall have large free passing area, and low

friction loss coefficient.

For piping systems with hot liquids, thermal expansions are to be taken

into account and compensators shall be mounted in accordance with

these expansions. Caution shall be exercised to avoid the loading of

pump in this installation.

6.3.2. Specification of Work in Piping Installation

In installation of pipes, follow the procedures below certainly.

•

Take out the guards (placed by the manufacturer) from suction and

discharge openings of the pump.

•

Close the suction and discharge flanges with rubber gaskets. This

precaution is important to avoid the undesired substances (weld crust,

weld slag, sand, stone, wood piece etc.) get into the pump. Do not take

off this gasket until the installation is completed.

•

Start the installation of piping from the pump side. Do the necessary

assembling and welding of the parts in a successive order.

•

In these operations, do not neglect to put the necessary supports in

their respected locations.

•

Following above procedure, complete all piping system at suction side

up to the suction tank (or foot valve if available), at discharge side up to

do discharge collector and discharge pipe.

•

When all installation and welding process is done and the heat

dissipated by welding is removed, dismantle all the bolted connections

from the suction tank to discharge pipe. Take out all demountable parts.

•

Clean these parts and then paint body coat completely inside and

outside.

•

Mount the parts again in their intended places. However, this time start

from the discharge line and move downward to the pump. In this

instance, do not forget to check the flange gaskets. If needed, (for

example deformation during welding) replace them.

•

Concerning the connection of the pump flanges to piping, in case of

misalignment of axis and flange holes, do not force the system to

eliminate the misalignment. Forcing the system may cause difficult-to-

correct problems.

•

If there is an axial misalignment between the flanges of the pump and

the pipe, due to the welding or any other reasons, cut the pipe from a

suitable location in order to fix the problem. Connect the pipe (pump

side) to the pump. After carrying out the necessary correction, connect

the parts again by welding.

•

Dismantle and clean the last welded part. Repaint again and mount on

its place.

•

After all these processes are accomplished, remove the rubber gasket

from the suction and discharge openings. Open their holes and mount

them again on their intended place.

6.3.3. Specification of Work after Installation of Piping and Piping

System

Installing Pipes

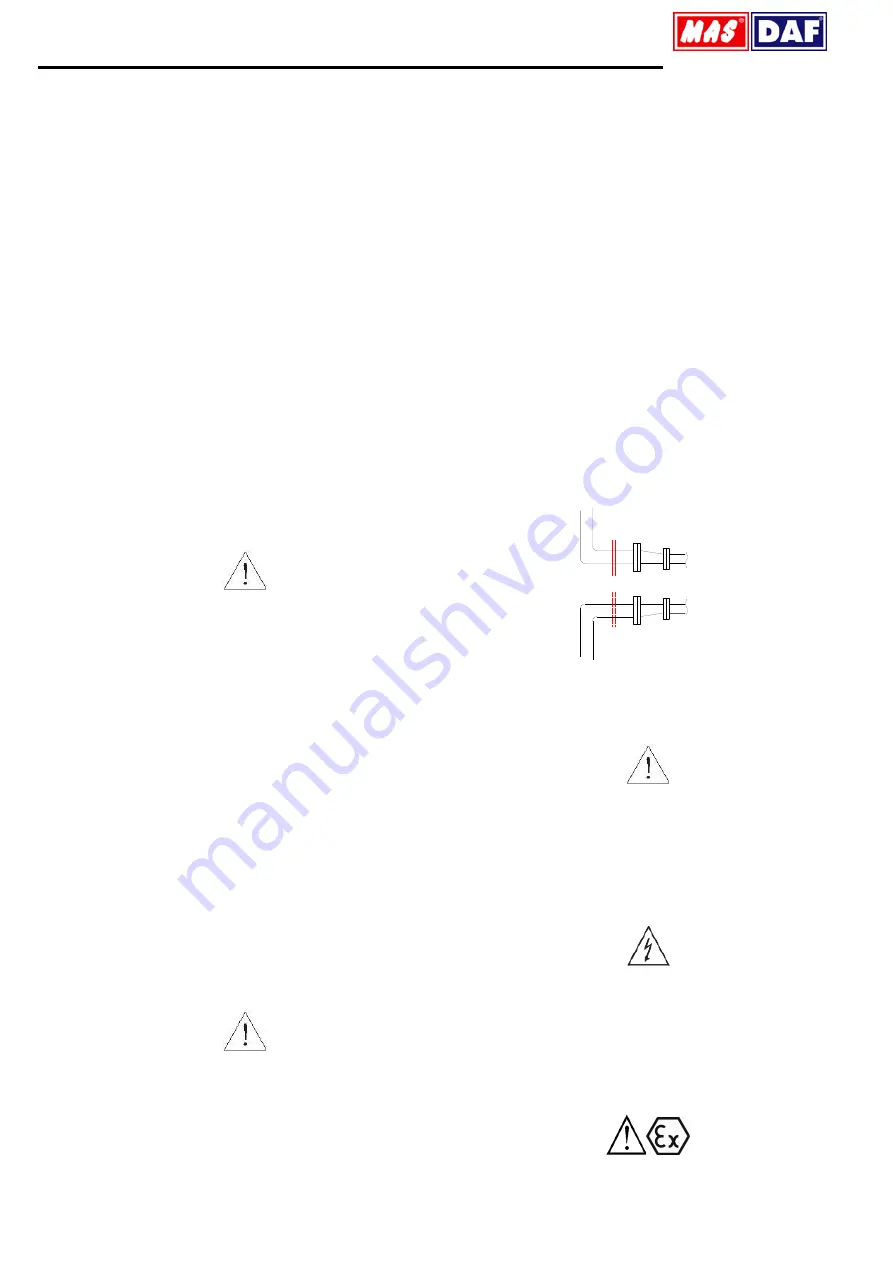

Suction line (top wiew)

Suction line (bottom wiew)

Suction flange

Suction flange

Figure 3:

Piping System

An illustrative piping system is shown in Figure 6. Appropriate

manometers shall be mounted on suction and discharge pipe lines.

Complete the auxiliary pipe connections in piping system if exist (cooling

to bearing housing, and stuffing box (seal), relief pipe, oil pipe etc.)

6.4. Motor Connection

Motor shall be connected by an electrical technician according to the

connection (switch) diagram. Local electricity policies regulations have to

be applied.

•

Electrical connections have to be made by authorized electricians.

•

In dismantling the pump, make sure the electricity is cut off before

taking the motor cover out.

•

Use the appropriate electrical connection to the motor.

In environments where there is a risk of explosion, prescribed protective

law and regulations shall be applied by competent authorities.

Connection points of the cable ends must be away from environment with

explosion risk or provide allowable conditions for II 2G device category.

Never operate pump units not connected electrical cable

connections correctly

.