27

Appendix

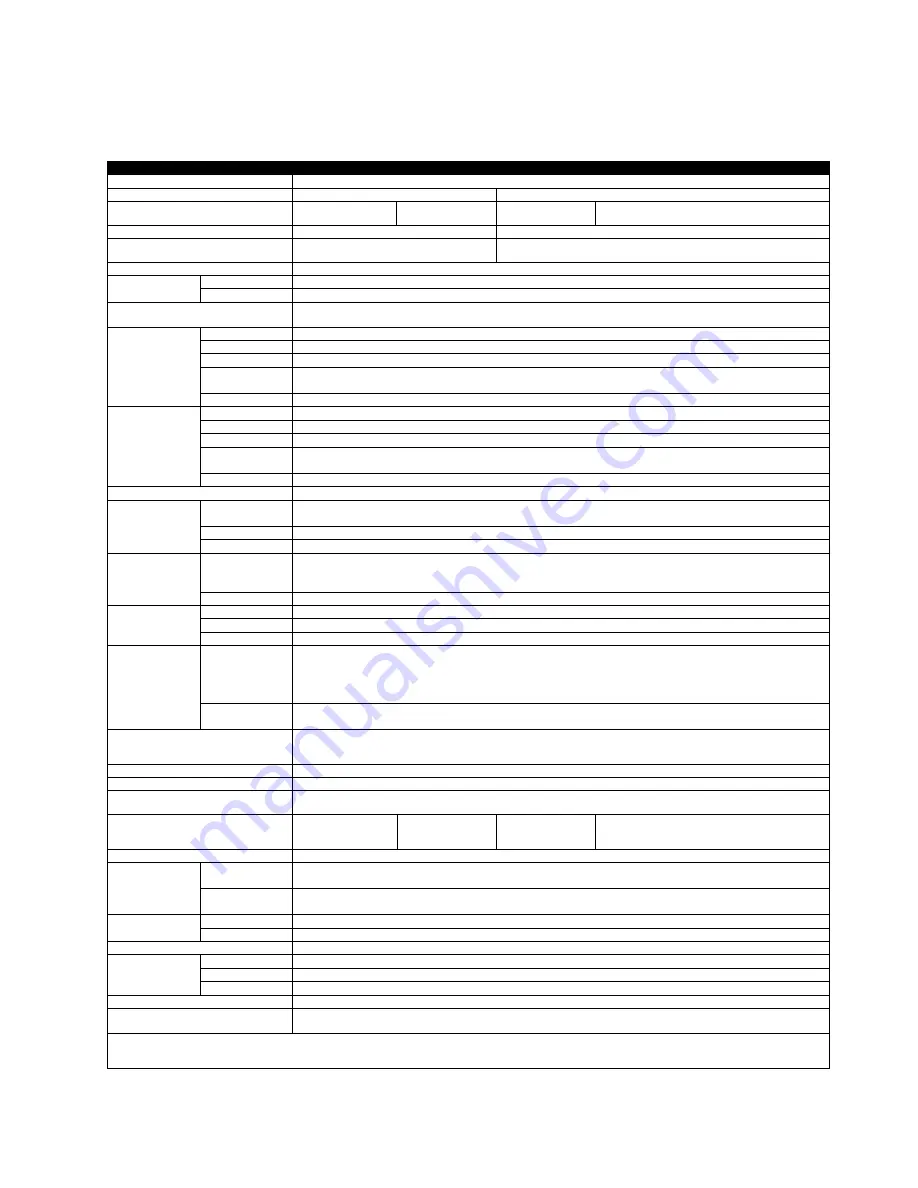

Model

ME120

MD120

ME130

MD130

Print Method

Thermal Transfer / Direct Thermal

Resolution

203 dpi (8 dots/mm)

300 dpi (12 dots/mm)

Print Speed

Up to 5IPS (127

mm/s)**

Up to 4 IPS (102

mm/s)**

4 IPS (102

mm/s)**

3 IPS (76 mm/s)**

Print Width

4.25” (108 mm)

4.16” (105.7 mm)

Print Length

Min. 0.16” (4 mm)**

Max. 68” (1727 mm)

Min. 0.16” (4 mm)**

Max. 30” (762 mm)

Processor

32 Bit RISC CPU

Memory

Flash

8MB Flash (4MB for user storage)

SDRAM

16MB

Sensor Type

Adjustable reflective sensor

2 fixed transmissive sensors, central aligned

Media

Types

Continuous form, gap labels, black mark sensing, and punched hole; label length set by auto sensing or programming

Width

1” (25.4 mm) Min. - 4.64” (118 mm) Max.

Thickness

0.003” (0.06 mm) Min. - 0.01” (0.25 mm) Max.**

Label

Roll

Diameter

Max. 5” (127 mm)

Core Diameter

1” (25.4 mm), 1.5” (38.1mm), 3” (76.2mm)

Ribbon

Types

Wax, wax/resin, resin

Length

981’ (300 m)

Width

1.18” Min. - 4.33” (30 mm - 110 mm) Max.

Ribbon

Roll

Diameter

2.67“ (68 mm)

Core Diameter

Core diameter: 1” (25.4 mm)

Printer Language

EZPL, GEPL, GZPL auto switch

Software

Label

Design

Software

LabelPro

Driver

Compatible with Windows 2000 / XP / VISTA / Windows 7 / Windows 8.1

DLL/SKD

Support Win CE, .NET, Andriod, Windows Mobile, Windows 2000 / XP / VISTA / Windows 7 / Windows 8.1

Resident Fonts

Bitmap Fonts

6, 8, 10, 12, 14, 18, 24, 30, 16X26 and OCR A & B

90°, 180°, 270° rotatable, single characters 90°, 180°, 270° rotatable

8 times expandable in horizontal and vertical directions

TTF Fonts

Scalable fonts 90°, 180°, 270° rotatable

Download Fonts

Bitmap Fonts

90°, 180°, 270° rotatable, single characters 90°, 180°, 270° rotatable

Asian Fonts

90°, 180°, 270° rotatable and 8 times expandable in horizontal and vertical directions

TTF Fonts

Scalable fonts 90°, 180°, 270° rotatable

Barcodes

1-D Bar codes

Code 39, Code 93, EAN-8, EAN-13, EAN 8/13 (with 2 & 5 digits extension), UPC-A, UPC-E, UPC-A and UPC-E with

EAN 2 or 5 digit extension, Interleaved 2-of-5 (I 2 of 5), Interleaved 2- o-f 5 with Shipping Bearer Bars, Codabar, Code

128 (subset A, B, C), EAN 128, RPS 128, UCC 128, UCC/EAN-128 K-Mart, Random Weight, Postnet, ITF 14, China

Postal Code, HIBC, MSI, Plessey, Telepen, FIM, GS1 DataBar, German Post Code, Planet 11 & 13 digit, Japanese

Postnet, Standard 2 of 5, Industrial 2 of 5 , Logmars, Code 11, ISBT – 128 , Code 32

2-D Bar codes

PDF417, Datamatrix code, MaxiCode, QR code, Micro PDF417, Micro QR code and Aztec code, Code 49, Codablock

F , TLC 39

Code Pages

CODEPAGE 437, 850, 851, 852, 855, 857, 860, 861, 862, 863, 865, 866, 869, 737

WINDOWS 1250, 1251, 1252, 1253, 1254, 1255, 1257

Unicode (UTF8, UTF16)

Graphics

Resident graphic file types are BMP and PCX, other graphic formats are downloadable from the software

Interfaces

USB Device (B-Type)

Control Panel

One Tri-color LED: Power (Green, Orange and Red)

Function Key: FEED

Power

Auto Switching 100-

240VAC, 50-60Hz.

Wall Mount Auto

Switching 100-

240VAC, 50-60Hz

Auto Switching

100-240VAC, 50-

60Hz.

Wall Mount Auto Switching 100-240VAC, 50-60Hz

Real Time Clock

N/A

Environment

Operation

Temperature

41°F to 104°F (5°C to 40°C)

Storage

Temperature

-

4°F to 122°F (-20°C to 50°C)

Humidity

Operation

30-85%, non-condensing.

Storage

10-90%, non-condensing.

Agency Approvals

CE(EMC), FCC Class A, CB, CCC, UL, cUL,BIS,KC

Dimension

Length

11.2” (285 mm)

Height

6.93” (176 mm)

Width

9.17” (233 mm)

Weight

6.33 lbs (2.87Kg) ,excluding consumables

Options & Accessories

External label roll holder for 10”(250 mm) O.D. label rolls

External label rewinder T10

* Specifications are subject to change without notice. All company and/or product names are trademarks and/or registered trademarks of their respective owners.

** Minimum print height and maximum print speed specification compliance can be dependent on non-standard material variables such as label type, thickness,

spacing, liner construction, etc. GoDEX is pleased to test non-standard materials for minimum print height, and maximum print speed capability.