Omni/Uni Flash Operation

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

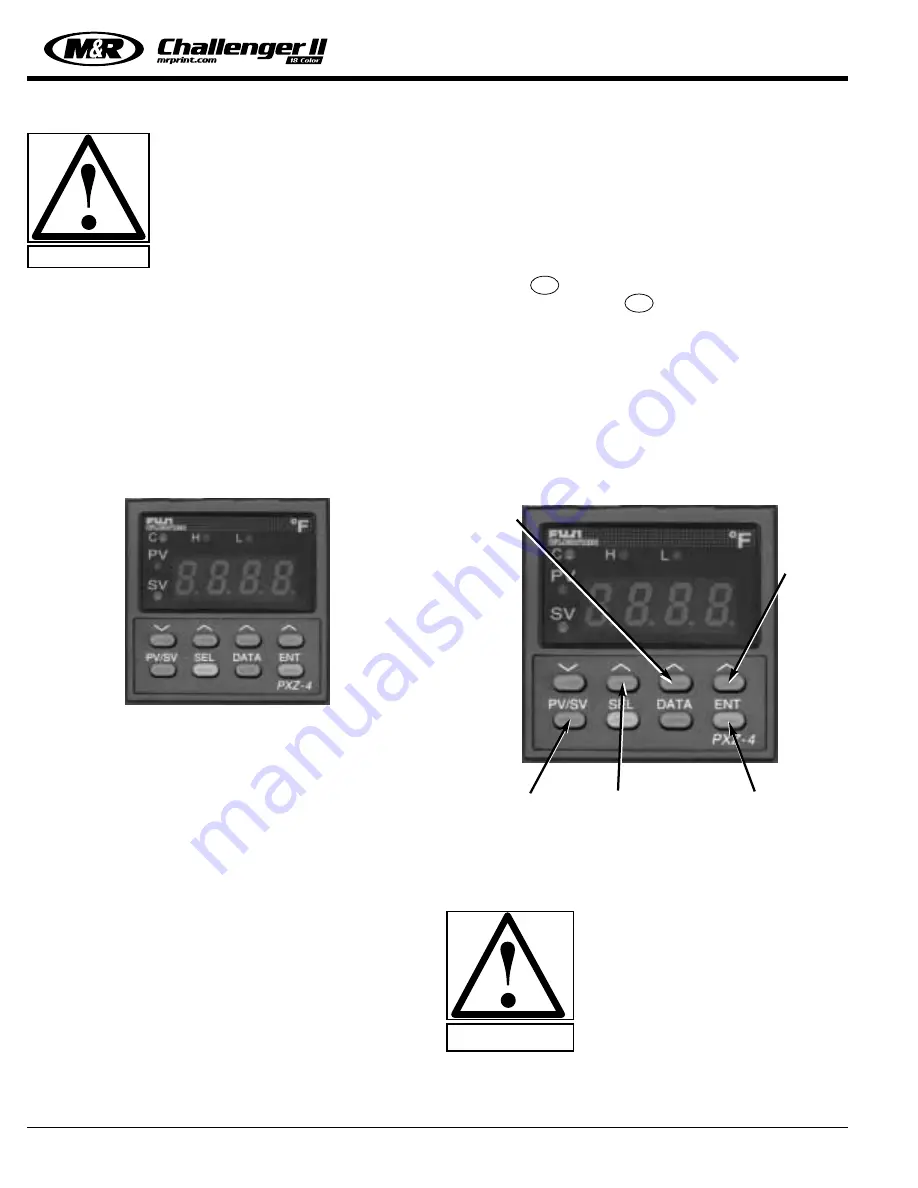

4.To check the current process temperature, press the

“PV/SV” key so the red L.E.D. lights beside the PV

(Measured Value) indication. The number displayed will be

the current process temperature as measured by the ther-

mocouple in the flash panel.

5. To lower the process temperature, press the PV/SV key

so the green L.E.D. light beside the SV indicator comes on.

Press the key. Under each digit that you want to

change, you will use the

key to decrease the num-

ber value on each digit to get the numbers to flash. Once

the programmed temperature has been selected, press the

enter key. The display will stop flashing. Now press the

PV/SV key so the red L.E.D. light beside the PV is showing

the temperature as measured by the thermocouple, in the

flash panel (See Fig. 13).

WARNING! The electrical power switch

for the Challenger Series II must NOT

be turned “OFF” before the flash cure

panel has cooled down to at least 99

degrees or lower.

WARNING! Be careful not to adjust the

inboard or outboard speed too fast.

Higher speeds can lead to premature

failure of the infrared heat panel due to

mechanical shock generated by the

higher inboard/outboard speed. Always

adjust the inboard or outboard speed

so the heat panel moves in and out of

position smoothly without jerking

motion or vibration.

11. Adjust the digital temperature control for optimum flash

curing of garments. We suggest that you run a few tests to

determine the proper heat setting before beginning produc-

tion. Proper cure temperature will be determined in large

part by the type and weight of the garment. In addition, the

type of ink used will also have an effect on the proper cure

temperature. 100% cotton t-shirt, start at 800 degrees F.

For 100% cotton sweat shirts, start at 850 degrees F. (See

Fig. 12)

Operation of the Temperature Controller:

1. Turn “On” the electrical power to the Omni/Uni Flash cure

unit.

2. Press the “PV/SV” key so that the green L.E.D. beside the

“PV” (Present Value) or “SV” (Set Value) on the display illu-

minates.

3. To set the desired process temperature, press the key

under each individual numeric number. For example- to set

for 250 degrees, push the 10 digit key one time. The 10 indi-

cation will flash. Push the 10 digit key 5 times to indicate 5.

The display will read 0050. Now press the 100 digit key. The

100 digit indication will flash. Push the 100 digit key 2 times

so the number 2 appears in the indicator. The display will

now read 0250. Press the ENTER key. The display will stop

flashing, and the set value of 250 degrees will now be indi-

cated on the display.

26

WARNING!

WARNING!

Fig. 11

V

V

Fig. 13

Press this

key to

indicate

the set

value.

Press ENT

to Enter

set value

into the

control.

Press this

key to set

the 100

digit

value.

Press this

key to set

1 digit

value.

Press this

key to set

10 digit

value.

Summary of Contents for CHALLENGER II Series

Page 4: ......

Page 6: ......

Page 8: ......

Page 18: ...M R Printing Equipment Inc Glen Ellyn Illinois 10 Specifications NOTES ...

Page 38: ...Quartz Flash Operation M R Printing Equipment Inc Glen Ellyn Illinois NOTES 30 ...

Page 72: ...081200MS PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 64 ...

Page 84: ...PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 081200MS 76 ...

Page 88: ...081200MS PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 80 ...

Page 104: ...PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 96 ...

Page 112: ...PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 104 ...

Page 114: ...081200MS PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 106 ...

Page 116: ...PREVENTIVE MAINTENANCE PROCEDURE CHALLENGER Series II NOTES 108 ...

Page 118: ...081200MS 110 This page left blank intentionally ...

Page 122: ...Leveling the Pallets M R Printing Equipment Inc Glen Ellyn Illinois 114 NOTES ...

Page 128: ...Idec Relay Identification NOTES 120 ...

Page 144: ...Trouble Shooting Procedure NOTES 136 ...

Page 153: ......

Page 154: ......

Page 156: ......

Page 160: ......

Page 162: ......

Page 164: ......

Page 166: ......

Page 168: ......

Page 172: ......

Page 174: ......

Page 176: ......

Page 178: ......

Page 180: ......

Page 182: ......

Page 184: ......

Page 186: ......

Page 188: ......

Page 190: ......

Page 192: ......

Page 194: ......

Page 196: ......

Page 198: ......

Page 200: ......

Page 202: ......

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 212: ......

Page 214: ......

Page 216: ......

Page 218: ......

Page 220: ......

Page 222: ......

Page 224: ......

Page 228: ......

Page 230: ......

Page 232: ......

Page 234: ......

Page 240: ......