Wipe the device with a clean cloth or blow it out with compressed air at low pressure.

Excessive accumulation of metal dust can cause electricity to be conducted from the

internal parts to exposed metal parts!

If the power tool's power cord is damaged, it must be replaced with a specially

prepared power cord that is available from the customer service organization.

Only put the power tool on the nut / screw when it is switched off, otherwise the

rotating tool bits may slip off.

The torque depends on the duration of the impact. The maximum torque achieved

results from the sum of all individual torques achieved through impacts. The maximum

torque is reached after a stroke duration of 3-5 seconds. After this time, the tightening

torque only increases slightly. On the other hand, the gear housing may heat up

heavily.

Note: The consequences of excessive heating may cause high wear and tear on all

hammer mechanism parts and require high lubricant.

Screw connections with a hard, springy or soft seat

With a springy or soft seat, the maximum tightening torque is lower than with a hard

seat. A significantly longer impact time is also required.

Renewal of accessories

Worn or damaged accessories must be replaced immediately.

The following use cases result accordingly:

- A hard seat is provided for screw connections from metal to metal when using

washers. The maximum torque is reached after a relatively short impact time

(steep characteristic curve). Unnecessarily long striking times only damage the

machine.

- A Resilient fit is given for screw connections from metal to metal, but when using

spring washers, disc springs, studs or screws / nuts with a conical seat and when

using extensions.

- A soft fit is given for screwing of metal on wood, or use of lead or fiber washers

as a base.

If the torques achieved in a sequence of impacts are measured in the experiment and

transferred to a diagram, the curve of a torque curve is obtained. The height of the

curve corresponds to the maximum achievable torque, the steepness shows the time

in which this is achieved.

A torque curve depends on the following factors:

- Strength of the screws / nuts

- Type of base (washer, disc spring, seal)

- Strength of the material to be screwed

- Lubrication conditions on the screw connection

The impact duration must be determined for each required tightening torque. The

tightening torque actually achieved must always be checked with a torque wrench.

7

Work instructions

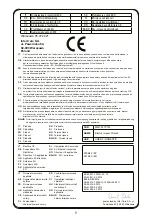

Summary of Contents for MMT A170 703

Page 10: ......