16 ENGLISH

Carrying tool

Before carrying the tool, always apply the chain brake

and remove the battery cartridges from the tool. Then

attach the guide bar cover. Also cover the battery car-

tridge with the battery cover.

►

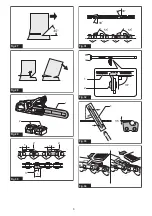

Fig.29:

1.

Guide bar cover

2.

Battery cover

MAINTENANCE

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed before

attempting to perform inspection or maintenance.

CAUTION:

Always wear gloves when perform-

ing any inspection or maintenance.

NOTICE:

Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

Sharpening the saw chain

Sharpen the saw chain when:

•

Mealy sawdust is produced when damp wood is cut;

•

The chain penetrates the wood with difficulty, even

when heavy pressure is applied;

•

The cutting edge is obviously damaged;

•

The saw pulls to the left or right in the wood.

(caused by uneven sharpening of the saw chain or

damage to one side only)

Sharpen the saw chain frequently but a little each time.

Two or three strokes with a file are usually sufficient for

routine resharpening. When the saw chain has been

resharpened several times, have it sharpened in our

authorized service center.

Sharpening criteria:

WARNING:

An excessive distance between

the cutting edge and depth gauge increases the

risk of kickback.

►

Fig.30:

1.

Cutter length

2.

Distance between cutting

edge and depth gauge

3.

Minimum cutter

length (3 mm)

— All cutter length must be equal. Different cutter

lengths prevent the saw chain from running

smoothly and may cause the saw chain to break.

— Do not sharpen the chain when the cutter length

has reached 3 mm or shorter. The chain must be

replaced with new one.

— The chip thickness is determined by the distance between

the depth gauge (round nose) and the cutting edge.

— The best cutting results are obtained with following

distance between cutting edge and depth gauge.

•

Chain blade 90PX : 0.65 mm (0.025″)

•

Chain blade 91PX : 0.65 mm (0.025″)

►

Fig.31

— The sharpening angle of 30° must be the same on

all cutters. Different cutter angles cause the chain

to run roughly and unevenly, accelerate wear, and

lead to chain breaks.

— Use a suitable round file so that the proper sharp

-

ening angle is kept against the teeth.

•

Chain blade 90PX : 55°

•

Chain blade 91PX : 55°

File and file guiding

— Use a special round file (optional accessory) for

saw chains to sharpen the chain. Normal round

files are not suitable.

— Diameter of the round file for each saw chain is as

follows:

•

Chain blade 90PX : 4.5 mm (3/16″)

•

Chain blade 91PX : 4.0 mm (5/32″)

—

The file should only engage the cutter on the forward

stroke. Lift the file off the cutter on the return stroke.

— Sharpen the shortest cutter first. Then the length

of this shortest cutter becomes the standard for all

other cutters on the saw chain.

— Guide the file as shown in the figure.

►

Fig.32:

1.

File

2.

Saw chain

— The file can be guided more easily if a file holder

(optional accessory) is employed. The file holder

has markings for the correct sharpening angle of

30° (align the markings parallel to the saw chain)

and limits the depth of penetration (to 4/5 of the

file diameter).

►

Fig.33:

1.

File holder

— After sharpening the chain, check the height of the

depth gauge using the chain gauge tool (optional

accessory).

►

Fig.34

— Remove any projecting material, however small,

with a special flat file (optional accessory).

— Round off the front of the depth gauge again.

Cleaning the guide bar

Chips and sawdust will build up in the guide bar groove.

They may clog the bar groove and impair the oil flow.

Clean out the chips and sawdust every time when you

sharpen or replace the saw chain.

►

Fig.35

Cleaning the sprocket cover

Chips and saw dust will accumulate inside of the

sprocket cover. Remove the sprocket cover and saw

chain from the tool then clean the chips and saw dust.

►

Fig.36

Cleaning the oil discharge hole

Small dust or particles may be built up in the oil dis-

charge hole during operation. These dust or particles

may impair the oil to flow and cause an insufficient

lubrication on the whole saw chain. When a poor chain

oil delivery occurs at the top of guide bar, clean the oil

discharge hole as follows.

Summary of Contents for DUC305Z

Page 2: ...Fig 1 2 1 18 3 4 5 6 11 13 15 12 19 7 8 10 17 9 14 16 Fig 2 1 2 3 Fig 3 1 2 Fig 4 2 ...

Page 3: ...1 2 Fig 5 1 Fig 6 2 1 Fig 7 2 3 1 2 3 1 Fig 8 1 Fig 9 1 2 3 Fig 10 3 ...

Page 4: ...1 Fig 11 1 2 3 4 Fig 12 1 Fig 13 1 Fig 14 1 2 3 Fig 15 1 Fig 16 1 2 Fig 17 Fig 18 4 ...

Page 5: ...Fig 19 Fig 20 Fig 21 Fig 22 A B A B Fig 23 Fig 24 2 1 2 45o 1 45o Fig 25 1 2 2 3 3 Fig 26 5 ...

Page 7: ...Fig 35 Fig 36 2 1 Fig 37 1 2 Fig 38 1 2 Fig 39 7 ...