R

epair

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

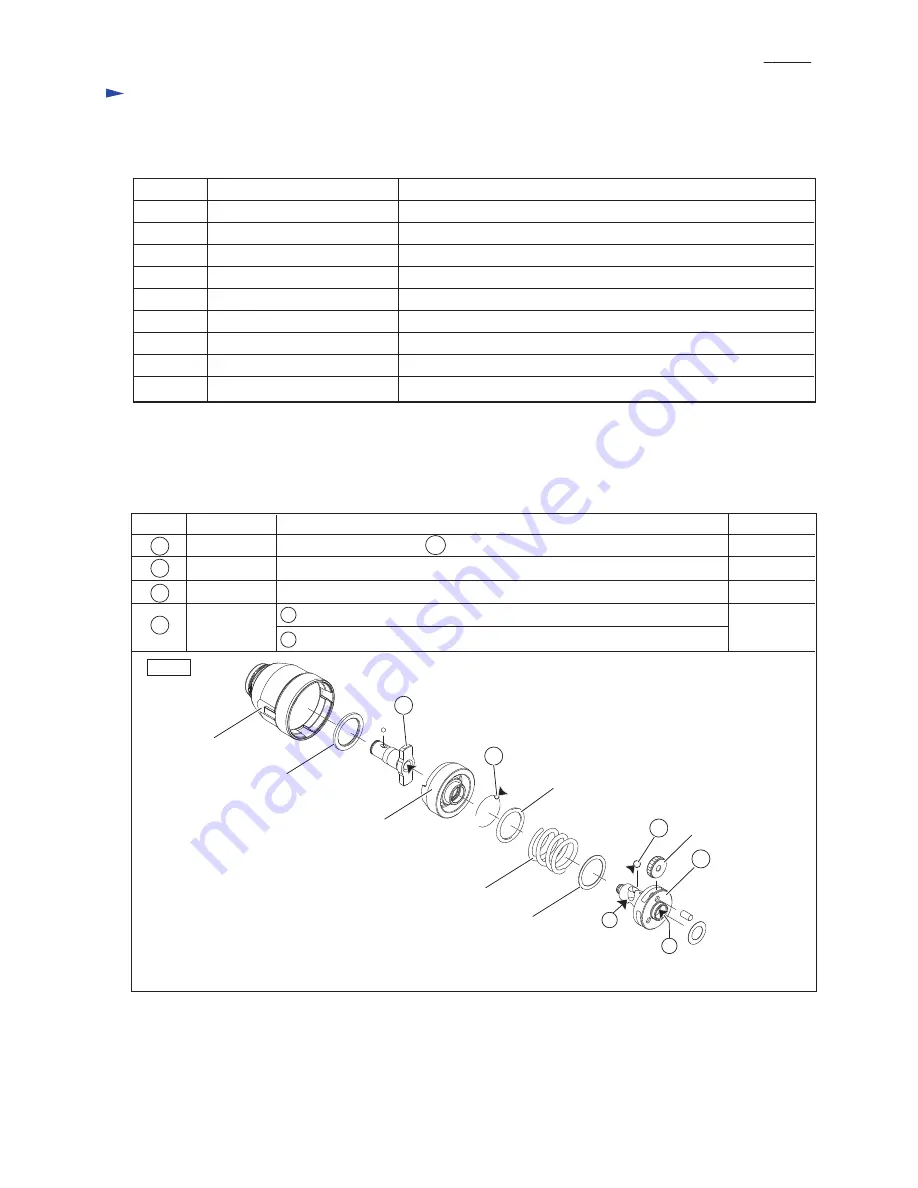

[2] LUBRICATION

Apply

Makita grease FA. No.2

to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

Fig. 1

Item No.

21

27

19

Description

Nylon washer 24

Hammer

Flat washer 24*

(1mm thickness/ Heat treated plate)

Flat washer 24*

(0.5mm thickness)

*They have the same inner diameter and outer diameter.

Spur gear 22

Compression spring 25

Hammer case complete

Amount

Portion to lubricate

25

19

Anvil

a little

a little

a little

approx. 2 g

21

Steel ball 3.5

Steel ball 5.6

In the accepting hole for Rotor

Drum portion

whole portion

whole portion

Spindle

25

27

In the accepting hole for 27 Spindle

b

a

b

a

Code No.

Description

Use for

1R041

Holding Socket 32-50 when disassembling Hammer case

1R045

Disassembling/assembling Hammer section

1R223

1R224

Disassembling Hammer case (Use with 1R223.)

1R232

Holding Anvil when disassembling Bit holder section

1R288

1R291

134847-1

Disassembling/assembling Hammer case

134848-9

Disassembling/assembling Hammer case

P 2/ 14

Disassembling Hammer case

Torque wrench shaft 20-90 N·m

Gear extractor

Vise plate

Ratchet head 12.7

Pipe 30

Magnetizing a screwdriver for easy removal of steel balls

Screwdriver magnetizer

Removing Ring spring 11 of Bit holder section

Retaining ring S & R Pliers

Socket 30-78

Socket 32-50