29 ENGLISH

►

Fig.49:

1.

Stopper pin

1.

Unlock the stopper pin so that the carriage can

slide freely.

2.

Secure the workpiece with the proper type of vise.

3.

Pull the carriage toward you fully.

4.

Switch on the tool without the saw blade making any

contact and wait until the saw blade attains full speed.

5.

Press the handle down and

push the carriage

toward the guide fence and through the workpiece.

6.

When the cut is completed, switch off the tool and

wait until the saw blade has come to a complete stop

before returning the blade to its fully elevated position.

Miter cutting

Refer to the section for adjusting the miter angle.

Bevel cut

WARNING:

After setting the blade for a bevel

cut, ensure that the carriage and saw blade will

have free travel throughout the entire range of the

intended cut before operating the tool.

Interruption

of the carriage or blade travel during the cutting opera-

tion may result in kickback and serious personal injury.

WARNING:

While making a bevel cut, keep

hands out of the path of the saw blade.

The angle

of the blade may confuse the operator as to the actual

blade path while cutting and contact with the blade

will result in serious personal injury.

WARNING:

The saw blade should not be raised

until it has come to a complete stop.

During a bevel

cut, the piece cut off may come to rest against the saw

blade. If the blade is raised while it is rotating, the cut-off

piece may be ejected by the blade causing the material

to fragment which may result in serious personal injury.

NOTICE:

When pressing down the handle, apply

pressure in parallel with the blade.

If a force is

applied perpendicularly to the turn base or if the pres-

sure direction is changed during a cut, the precision

of the cut will be impaired.

►

Fig.50

1.

Remove the upper fence on the side that you are

going to tilt the carriage.

2.

Unlock the stopper pin.

3.

Adjust the bevel angle according to the procedure

explained in the section for bevel angle adjustment.

Then tighten the knob.

4.

Secure the workpiece with a vise.

5.

Pull the carriage toward you fully.

6.

Switch on the tool without the blade making any

contact and wait until the blade attains full speed.

7.

Gently lower the handle to the fully lowered position

while applying pressure in parallel with the blade and

push

the carriage toward the guide fence to cut the workpiece.

8.

When the cut is completed, switch off the tool and

wait until the blade has come to a complete stop

before returning the blade to its fully elevated position.

Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter angle

is being cut on a workpiece. Compound cutting can be

performed at the angle shown in the table.

Miter angle

Bevel angle

Left and Right 0° - 45°

Left and Right 0° - 45°

When performing compound cutting, refer to the section

for press cutting, slide (push) cutting, miter cutting and

bevel cut.

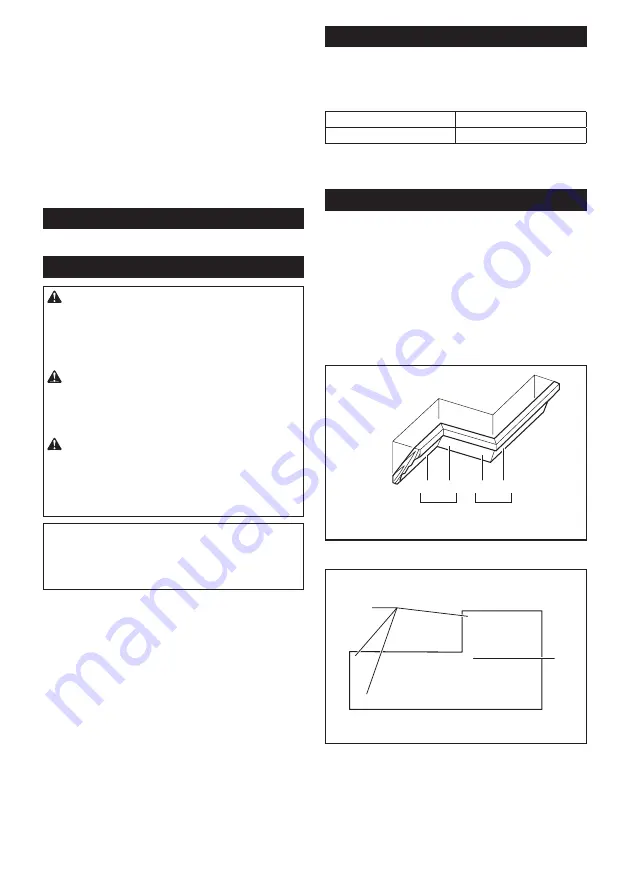

Cutting crown and cove moldings

Crown and cove moldings can be cut on a compound

miter saw with the moldings laid flat on the turn base.

There are two common types of crown moldings and

one type of cove moldings; 52/38° wall angle crown

molding, 45° wall angle crown molding and 45° wall

angle cove molding.

►

Fig.51:

1.

52/38° type crown molding

2.

45° type

crown molding

3.

45° type cove molding

There are crown and cove molding joints which are

made to fit "Inside" 90° corners ((a) and (b) in the figure)

and "Outside" 90° corners ((c) and (d) in the figure.)

(a) (b)

(c) (d)

1

2

1.

Inside corner

2.

Outside corner

2

(a)

(b)

(a)

(b)

(b)

(a)

(b)

(a)

(a)

(b)

(c)

(d)

1

1.

Inside corner

2.

Outside corner

Summary of Contents for DLS111ZU

Page 2: ...Fig 1 10 11 12 14 15 3 2 4 5 8 7 9 13 6 1 16 17 18 20 21 22 19 Fig 2 2 ...

Page 3: ...16 17 20 19 18 21 15 1 2 3 11 13 14 12 4 6 6 7 8 5 9 10 Fig 3 1 2 Fig 4 1 2 4 4 3 Fig 5 3 ...

Page 4: ...2 1 Fig 6 2 1 3 Fig 7 1 Fig 8 1 2 3 Fig 9 2 1 1 Fig 10 1 2 Fig 11 1 Fig 12 4 ...

Page 5: ...1 Fig 13 3 1 2 Fig 14 1 Fig 15 1 2 3 4 6 5 Fig 16 1 Fig 17 1 Fig 18 5 ...

Page 6: ...1 2 3 Fig 19 1 2 Fig 20 1 2 3 4 Fig 21 1 Fig 22 1 Fig 23 6 ...

Page 7: ...1 2 Fig 24 1 Fig 25 1 Fig 26 1 Fig 27 1 2 3 Fig 28 1 2 3 Fig 29 1 Fig 30 7 ...

Page 8: ...1 Fig 31 A B Fig 32 1 Fig 33 2 1 3 Fig 34 3 1 2 Fig 35 8 ...

Page 9: ...1 2 5 3 4 Fig 36 1 2 Fig 37 1 2 3 4 5 6 Fig 38 1 2 3 1 2 3 Fig 39 1 2 Fig 40 1 Fig 41 9 ...

Page 10: ...1 2 Fig 42 1 2 3 1 2 3 4 4 Fig 43 1 2 3 Fig 44 1 2 3 4 Fig 45 1 2 3 Fig 46 1 2 Fig 47 10 ...

Page 11: ...1 Fig 48 1 Fig 49 Fig 50 1 2 3 Fig 51 2 3 1 4 Fig 52 1 2 3 4 Fig 53 11 ...

Page 12: ...1 2 3 4 Fig 54 1 2 Fig 55 1 5 3 4 2 Fig 56 1 Fig 57 Fig 58 Fig 59 1 Fig 60 12 ...

Page 13: ...1 4 2 3 Fig 61 1 2 3 Fig 62 1 Fig 63 1 2 1 2 Fig 64 Fig 65 1 Fig 66 13 ...

Page 14: ...1 2 Fig 67 1 Fig 68 1 Fig 69 1 2 1 2 Fig 70 2 1 2 3 Fig 71 1 Fig 72 14 ...

Page 15: ...1 2 Fig 73 1 2 3 Fig 74 Fig 75 1 2 Fig 76 4 5 1 2 3 Fig 77 15 ...