12 ENGLISH

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

►

Fig.2:

1.

Indicator lamps

2.

Check button

Press the check button on the battery cartridge to indi

-

cate the remaining battery capacity. The indicator lamps

light up for a few seconds.

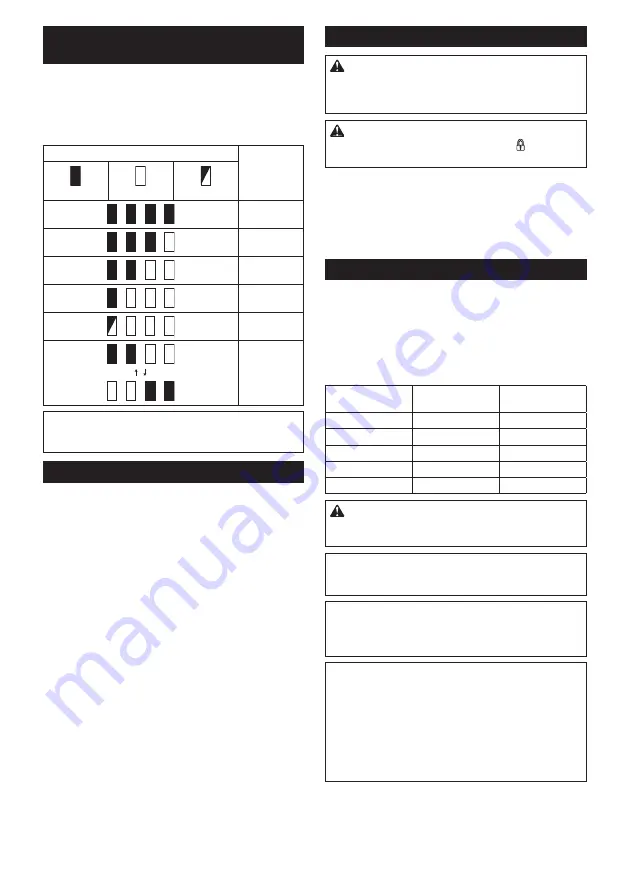

Indicator lamps

Remaining

capacity

Lighted

Off

Blinking

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE:

Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Tool / battery protection system

The tool is equipped with a tool/battery protection sys

-

tem. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will auto

-

matically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

When the battery is operated in a manner that causes

it to draw an abnormally high current, the tool automat

-

ically stops without any indication. In this situation, turn

the tool off and stop the application that caused the tool

to become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool or battery is overheated, the tool stops

automatically and the lamp blinks. In this case, let the

tool and battery cool before turning the tool on again.

Overdischarge protection

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the

tool and charge the battery.

Switch action

WARNING:

Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

CAUTION:

When not operating the tool,

depress the trigger-lock button from side to

lock the switch trigger in the OFF position.

►

Fig.3:

1.

Switch trigger

2.

Trigger-lock button

To prevent the switch trigger from accidentally pulled,

the trigger-lock button is provided. To start the tool,

depress the trigger-lock button from A side and pull the

switch trigger. Release the switch trigger to stop. After

use, press in the trigger-lock button from B side.

Speed change

The revolutions and blows per minute can be adjusted

by turning the adjusting dial. The dial is marked 1 (low

-

est speed) to 5 (full speed).

►

Fig.4:

1.

Adjusting dial

Refer to the table below for the relationship between the

number on the adjusting dial and the revolutions and

blows per minute.

Number

Revolutions per

minute

Blows per minute

5

500

2,900

4

470

2,700

3

380

2,150

2

290

1,650

1

250

1,450

CAUTION:

Do not turn the adjusting dial when

the tool is running. Failure to do so may result in

the loss of control of the tool and cause an injury.

NOTICE:

If the tool is operated continuously at

low speed for a long time, the motor will get over-

loaded, resulting in tool malfunction.

NOTICE:

The speed adjusting dial can be turned

only as far as 5 and back to 1. Do not force it past

5 or 1, or the speed adjusting function may no

longer work.

NOTE:

Soft no-load rotation function

When the speed adjusting dial is set to "3" or higher,

the tool automatically reduces the speed at no-load to

reduce the vibration under no-load. Once operation

starts with a bit against concrete, blows per minute

increase and reach the numbers as shown in the

table. When temperature is low and there is less

fluidity in grease, the tool may not have this function

even with the motor rotating.

Summary of Contents for DHR400ZKU

Page 2: ...1 2 3 Fig 1 1 2 Fig 2 B A 2 1 Fig 3 1 Fig 4 1 Fig 5 1 2 Fig 6 1 2 Fig 7 Fig 8 2 ...

Page 3: ...1 2 Fig 9 1 Fig 10 1 2 Fig 11 1 Fig 12 1 2 Fig 13 1 2 Fig 14 1 2 Fig 15 3 ...

Page 4: ...1 2 Fig 16 1 2 3 Fig 17 1 2 3 4 Fig 18 1 2 Fig 19 1 Fig 20 1 Fig 21 4 ...

Page 5: ...1 2 3 Fig 22 1 2 3 Fig 23 1 2 Fig 24 1 2 3 3 Fig 25 1 Fig 26 Fig 27 Fig 28 5 ...

Page 6: ...Fig 29 Fig 30 1 Fig 31 1 2 3 4 Fig 32 1 2 3 Fig 33 1 Fig 34 6 ...

Page 7: ...1 2 1 2 Fig 35 Fig 36 1 Fig 37 1 2 Fig 38 1 Fig 39 1 Fig 40 7 ...

Page 8: ...1 2 1 2 Fig 41 8 ...