19 ENGLISH

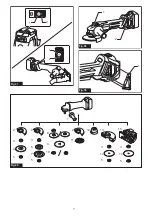

When installing the diamond wheel:

►

Fig.21:

1.

Lock nut

2.

Diamond wheel (Thinner than

4 mm (5/32"))

3.

Diamond wheel (4 mm

(5/32") or thicker)

4.

Inner flange

For 115 mm (4 - 1/2") / 125 mm (5")

model

When installing the abrasive cut-off wheel:

►

Fig.22:

1.

Lock nut

2.

Abrasive cut-off wheel

(Thinner than 4 mm (5/32"))

3.

Abrasive cut-

off wheel (4 mm (5/32") or thicker)

4.

Inner

flange

When installing the diamond wheel:

►

Fig.23:

1.

Lock nut

2.

Diamond wheel (Thinner than

4 mm (5/32"))

3.

Diamond wheel (4 mm

(5/32") or thicker)

4.

Inner flange

Operation with wire cup brush

Optional accessory

CAUTION:

Check operation of brush by run-

ning tool with no load, insuring that no one is in

front of or in line with brush.

CAUTION:

Do not use brush that is damaged,

or which is out of balance.

Use of damaged brush

could increase potential for injury from contact with

broken brush wires.

►

Fig.24:

1.

Wire cup brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire cup

brush onto spindle and tighten with supplied wrench.

NOTICE:

Avoid applying too much pressure

which causes over bending of wires when using

brush.

It may lead to premature breakage.

Operation with wire wheel brush

Optional accessory

CAUTION:

Check operation of wire wheel

brush by running tool with no load, insuring that

no one is in front of or in line with the wire wheel

brush.

CAUTION:

Do not use wire wheel brush that

is damaged, or which is out of balance.

Use of

damaged wire wheel brush could increase potential

for injury from contact with broken wires.

CAUTION:

ALWAYS use guard with wire

wheel brushes, assuring diameter of wheel fits

inside guard.

Wheel can shatter during use and

guard helps to reduce chances of personal injury.

►

Fig.25:

1.

Wire wheel brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire wheel

brush onto spindle and tighten with the wrenches.

NOTICE:

Avoid applying too much pressure

which causes over bending of wires when

using wire wheel brush.

It may lead to premature

breakage.

WIRELESS ACTIVATION

FUNCTION

For DGA418/DGA468/DGA518 only

What you can do with the wireless

activation function

The wireless activation function enables clean and com-

fortable operation. By connecting a supported vacuum

cleaner to the tool, you can run the vacuum cleaner

automatically along with the switch operation of the tool.

►

Fig.26

To use the wireless activation function, prepare follow-

ing items:

•

A wireless unit (optional accessory)

•

A vacuum cleaner which supports the wireless

activation function

The overview of the wireless activation function

setting is as follows. Refer to each section for detail

procedures.

1.

Installing the wireless unit

2.

Tool registration for the vacuum cleaner

3.

Starting the wireless activation function

Installing the wireless unit

Optional accessory

CAUTION:

Place the tool on a flat and stable

surface when installing the wireless unit.

NOTICE:

Clean the dust and dirt on the tool

before installing the wireless unit.

Dust or dirt

may cause malfunction if it comes into the slot of the

wireless unit.

NOTICE:

To prevent the malfunction caused by

static, touch a static discharging material, such

as a metal part of the tool, before picking up the

wireless unit.

NOTICE:

When installing the wireless unit,

always be sure that the wireless unit is inserted

in the correct direction and the lid is completely

closed.

1.

Open the lid on the tool as shown in the figure.

►

Fig.27:

1.

Lid

2.

Insert the wireless unit to the slot and then close

the lid.

When inserting the wireless unit, align the projections

with the recessed portions on the slot.

►

Fig.28:

1.

Wireless unit

2.

Projection

3.

Lid

4.

Recessed portion