P 5 / 9

R

epair

[3] -1. Disassembling/Assembling Hammering Mechanism (cont.)

Do the reverse of assembling steps.

Note:

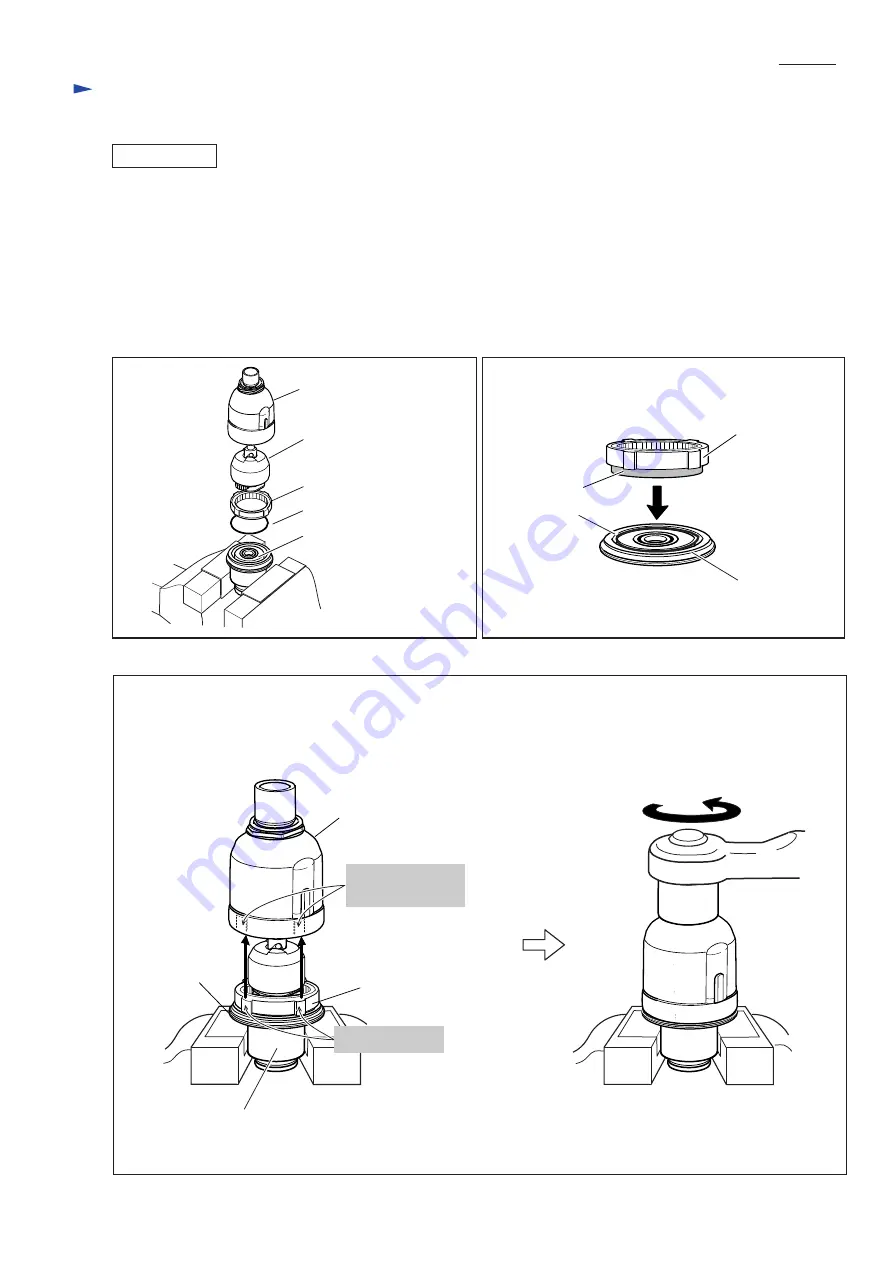

1) Assemble by piling component parts on Bearing box as illustrated in Fig. 10.

2) Make sure that twenty-six 3.5 Steel balls are in place inside Hammer.

3) Do not forget to install O ring 40 when assembling Internal gear 51 to Bearing box. (Fig. 11)

4) Internal gear 51 is not reversible when assembled to Bearing box. Be sure to assemble so that the stepped end of

the gear face Bearing box. (Fig. 11)

5) Assemble Hammer case complete to Bearing box as illustrated in Fig. 12.

Fig. 12

Bearing box

Hammer case complete

Socket 32-50 for fixing Bearing box

four projections

Internal gear 51

ASSEMBLING

Fig. 11

Fig. 10

Internal gear 51

O ring 40

Bearing box

Hammering mechanism

Hammer case

Fit Hammer case complete over Internal gear 51 with

the four grooves on the inside of Hammer case complete

aligned with the corresponding projections on Internal gear 51.

Then, using No.1R224 and No.1R223,

fasten Hammer case complete to

Bearing box by turning counterclockwise

to the recommended torque of 30 - 40 N.m.

four grooves on

the inside surface

Internal gear 51

Bearing box

O ring 40

stepped end