P 11/ 13

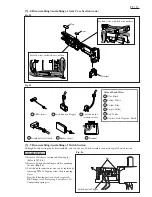

Fig. 29

W

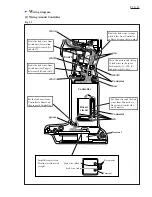

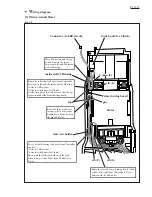

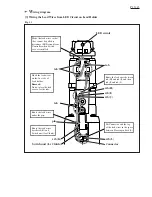

iring diagram

Switch

Terminal

Receptacles

Terminal

Lead wire (black)

Lead wire (red)

Install Receptacles on

Terminal as illustrated

to right.

Buzzer

circuit

groove

Put the lead wires from

Controller to Buzzer on

the groove in Controller.

Put Connector and the lead

wires from Controller to

Buzzer between the ribs

on Controller.

Place Connectors and the sag

of lead wires in the space

between ribs (A)- (B)- (C)

and pins- rib (D)- boss.

Controller

Route the lead wires (orange,

white, blue) from Controller

to Stator between the two pins.

Connector

Connector

rib

boss

rib (D)

pin

rib (C)

rib (B)

rib (A)

Route the lead wires from

Switch unit (for Trigger)

between rib (B) and rib (C).

Route the lead wires from

Switch unit (for rotation

reverse) between rib (A)

and rib (C).

[1] Wiring Around Controller