11 ENGLISH

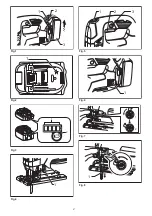

Dust extraction

The dust nozzle (optional accessory) is recommended

to perform clean cutting operations.

►

Fig.12:

1.

Dust nozzle

2.

Base

To attach the dust nozzle on the tool, insert the hook of

dust nozzle into the hole in the base.

►

Fig.13:

1.

Clamp screw

To secure the dust nozzle, tighten the clamp screw at

the front of the dust nozzle.

The dust nozzle can be installed on either left or right

side of the base.

►

Fig.14:

1.

Dust nozzle

2.

Hose for vacuum cleaner

Then connect a Makita vacuum cleaner to the dust

nozzle.

OPERATION

CAUTION:

•

Always hold the base flush with the workpiece.

Failure to do so may cause blade breakage,

resulting in a serious injury.

NOTE:

•

If the tool is operated continuously until the

battery cartridge has discharged, allow the tool

to rest for 15 minutes before proceeding with a

fresh battery.

►

Fig.15:

1.

Cutting line

2.

Base

Turn the tool on without the blade making any contact

and wait until the blade attains full speed. Then rest

the base flat on the workpiece and gently move the tool

forward along the previously marked cutting line.

When cutting curves, advance the tool very slowly.

Bevel cutting

CAUTION:

•

Always be sure that the tool is switched off and

the battery cartridge is removed before tilting

the base.

►

Fig.16

With the base tilted, you can make bevel cuts at any

angle between 0° and 45° (left or right).

►

Fig.17:

1.

Base

2.

Hex wrench

3.

Bolt

To tilt the base, loosen the bolt on the back of the base

with the hex wrench. Move the base so that the bolt is

positioned in the center of the bevel slot in the base.

►

Fig.18:

1.

Bevel slot

2.

Base

3.

Bolt

4.

Graduations

5.

V-notch

6.

Gear housing

Tilt the base until the desired bevel angle is obtained.

The V-notch of the gear housing indicates the bevel

angle by graduations. Then tighten the bolt firmly to

secure the base.

Front flush cuts

►

Fig.19:

1.

Base

2.

Hex wrench

3.

Bolt

Loosen the bolt on the back of the base with the hex

wrench and slide the base all the way back. Then

tighten the bolt to secure the base.

Cutouts

Cutouts can be made with either of two methods A or B.

A) Boring a starting hole:

►

Fig.20:

1.

Starting hole

•

For internal cutouts without a lead-in cut from an

edge, pre-drill a starting hole 12 mm or more in

diameter. Insert the blade into this hole to start

your cut.

B) Plunge cutting:

►

Fig.21

•

You need not bore a starting hole or make a

lead-in cut if you carefully do as follows.

1. Tilt the tool up on the front edge of the base with

the blade point positioned just above the work

-

piece surface.

2. Apply pressure to the tool so that the front edge of

the base will not move when you switch on the tool

and gently lower the back end of the tool slowly.

3. As the blade pierces the workpiece, slowly lower

the base of the tool down onto the workpiece

surface.

4.

Complete the cut in the normal manner.

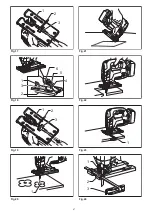

Finishing edges

►

Fig.22

To trim edges or make dimensional adjustments, run the

blade lightly along the cut edges.

Metal cutting

Always use a suitable coolant (cutting oil) when cutting

metal. Failure to do so will cause significant blade wear.

The underside of the workpiece can be greased instead

of using a coolant.

Rip fence set (optional accessory)

CAUTION:

•

Always be sure that the tool is switched off and

the battery cartridge is removed before installing

or removing accessories.

1. Straight cuts

►

Fig.23:

1.

Rip fence

When repeatedly cutting widths of 160 mm or less, use

of the rip fence will assure fast, clean, straight cuts.

►

Fig.24:

1.

Hex wrench

2.

Bolt

3.

Fence guide

To install, insert the rip fence into the rectangular hole

on the side of the tool base with the fence guide facing

down. Slide the rip fence to the desired cutting width

position, then tighten the bolt to secure it.

Summary of Contents for 0088381651882

Page 2: ...1 2 3 1 1 2 1 1 2 3 1 1 2 Fig 7 1 Fig 1 Fig 2 Fig 3 Fig 4 Fig 5 Fig 6 Fig 8 2 ...

Page 3: ...1 2 1 2 2 1 1 2 1 1 2 1 2 Fig 9 Fig 10 Fig 11 Fig 12 Fig 13 Fig 14 Fig 15 Fig 16 3 ...

Page 4: ...1 2 3 1 2 3 4 5 6 1 2 3 1 1 1 2 3 Fig 17 Fig 18 Fig 19 Fig 20 Fig 21 Fig 22 Fig 23 Fig 24 4 ...

Page 5: ...1 2 3 1 2 1 2 3 Fig 25 Fig 26 Fig 27 Fig 28 Fig 29 5 ...

Page 66: ...66 ...

Page 67: ...67 ...