9

8

x 1 8

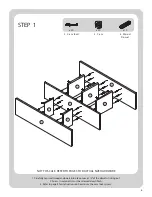

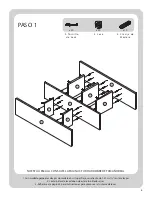

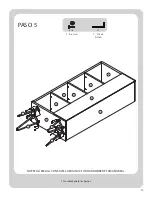

STEP 4

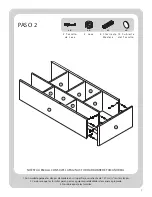

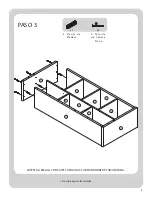

1. Do not over tighten screws.

6 . P a n H e a d

S c r e w

NOT TO SCALE. REFER TO PAGE 3 FOR ACTUAL SIZE HARDWARE.

Begin by installing all of the screws along one

edge of the back panel. Next, using a square

or tape measure, make sure that the case is

square. (if using a tape measure, the distance

from one corner, diagonally to the other corner

should be the same in both directions.) Install

the remaining screws, starting with the corners.