15

7.0

SITE REQUIREMENTS

7.3

Ventilation of Compartments

1. Where the appliance is installed in a cupboard or

compartment, no air vents are required. The

appliance will run sufficiently cool without ventilation.

2. Minimum clearances must be maintained and the

compartment should be large enough to house the

boiler and any ancillary equipment only.

7.4

Gas Supply

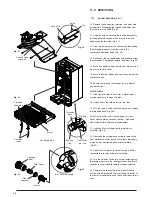

1. The gas installation should be in accordance with

the relevant standards. In GB this is BS 6891. In IE

this is the current edition of I.S. 813 “Domestic Gas

Installations”.

2. The connection to the appliance is a 22mm copper

tail located at the rear of the gas service cock

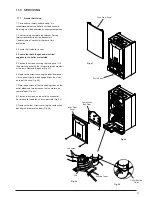

(Fig. 14).

3. Ensure that the pipework from the meter to the

appliance is of adequate size. Do not use pipes of a

smaller diameter than the boiler gas connection

(22mm).

7.5

Electrical Supply

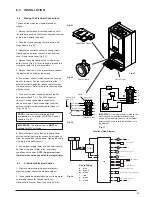

1. External wiring must be correctly earthed, polarised

and in accordance with relevant regulations/rules. In

GB this is the current I.E.E. Wiring Regulations. In IE

reference should be made to the current edition of

ETCI rules.

2. The mains supply is 230V ~ 50Hz fused at 3A

maximum.

NOTE:

The method of connection to the electricity

supply must facilitate complete electrical isolation

of the appliance.

Connection may be via a fused double-pole

isolator with a contact separation of at least 3mm

in all poles and servicing the boiler and system

controls only.

Fig. 14

Gas Service Cock

Summary of Contents for Combi 24 HE

Page 45: ...45 16 0 NOTES ...