8

Actuator Orientation Change / Replacement

8

.1

8

.2

8

.3

8

.4

8

.5

8

.6

8

.7

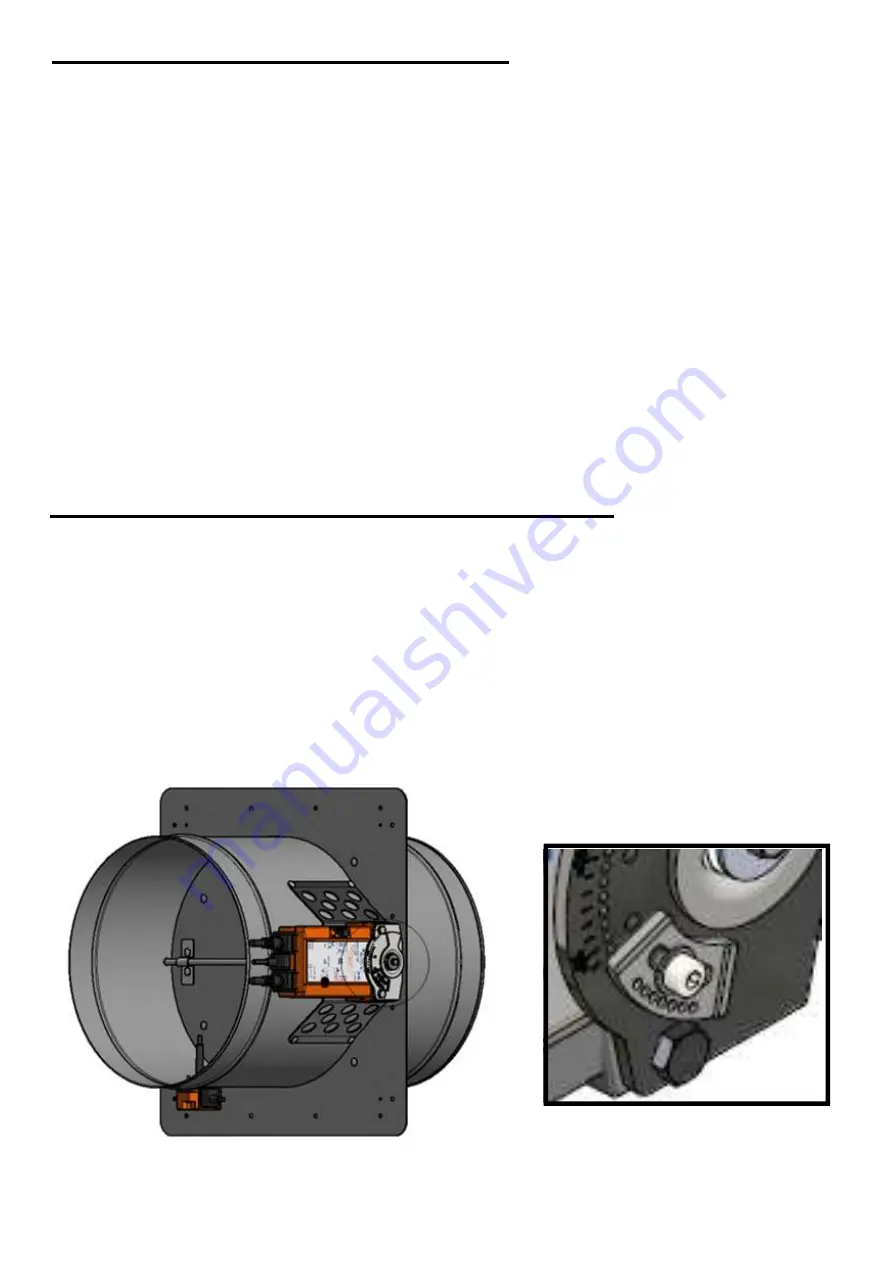

If required, the orientation may be changed to +90° or -90° from default ‘in-

line-with-duct’.

Ensure power to actuator is removed and allow actuator to travel to end

position.

Unscrew the 8mm AF head screw (central motor retaining screw) and

remove the set-point assembly

.

Remove the 10mm AF head screws (motor body retaining bolts). (It may be

necessary to partially wind the actuator a few degrees with the aid of the

manual reset key to release residual torque).

Remove the actuator and refit in new position w

wiitthhoouutt changing the blade’s

position.

Secure with the 10mm AF head screws (5Nm), followed by the ’

set point

assembly’ and 8mm AF head screw (3Nm).

Test (refer to section 1

2

).

9

Setting of Damper mid set-point Position (optional)

9

.1

9

.2

9

.3

Dampers are supplied with actuators set to travel to ‘fully open’ position by

default.

Optionally, dampers can be set so that the ‘open position’ is restricted to

between 30° to 90° (60° range). This is for system air balancing purposes,

should it be required.

To utilise set-point positioning, temporarily release actuator

(using 2.5mm AF

allen key),

unscrew and reposition the positional limiter engaging into the

2mm dia holes (as below).

Note: Wiring (section 9

.5

), If using "open damper status" indication

.

8.

5

8.

6

Retighten the retaining screw to approx. 3Nm.

Re

-

apply power and check

desired

open position is attained.

9 Wiring

9.1

9.2

9.3

Refer to electrical specification on back page of this document

.

Dampers are supplied with actuators factory fitted and tested.

Connect wires in accordance with the wiring details below.

Test

.

(Refer to section 10

)

9

.

4

9.

4

Make the following connections to achieve damper status indication:

Closed - use 1&2

open when not fully open - use 4&6

open indication when mid set point function - use 1&3

4

7