10 Commissioning, Maintenance and Test

1

2

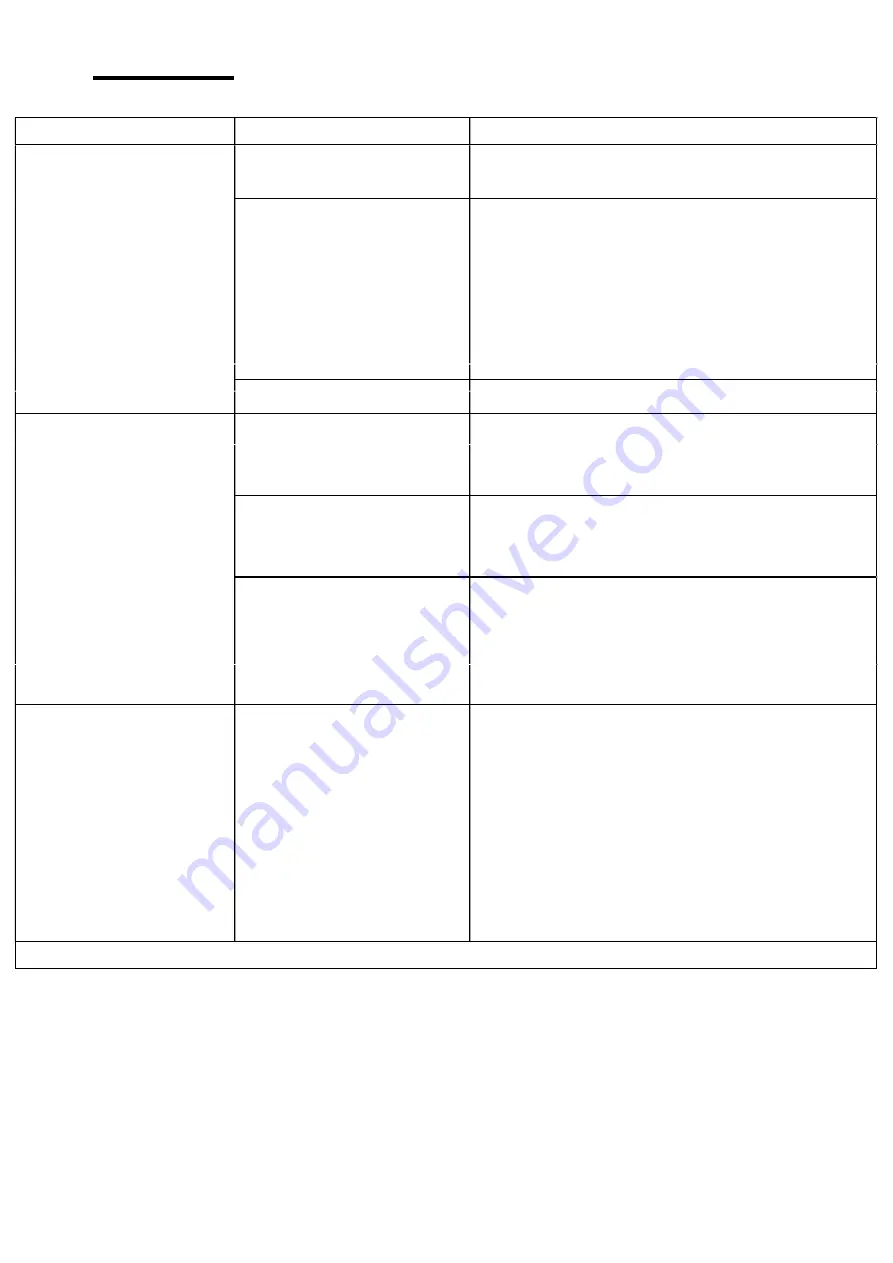

Fault Finding

Symptom

Fault

Corrective Action

Damper not in its

‘normal’ state or

Green LED on the

Thermal

Fuse

(TF) is not

illuminated

No power / incorrect

supply

Check supply/terminations Check signal

connections

If open circuit, replace probe

Actuator faulty

TF tripped. Remove

TF

from duct, separate

two halves,

continuity

check the two contacts

within the probe

section (or test with

new probe)

Replace

Damper does not

travel fully open /

closed

Damper seized

(Check

that the mid point function

is not set)

Clean and lubricate.

Operate manually a

couple of times then remove any excess

lubricant.

Casing

dented/damaged or

not round

Minor damage may be corrected carefully

with a mallet. (BSB always recommend

replacement of damaged dampers)

Foreign body

interfering with blade

sweep (commonly

rivet or screw)

Inspect inside of damper case. Remove

any offending item

Damper blade and/

or actuator does

not move open

D

amper internals have

been exposed to

excessive moisture

Report and log any damage found with actions to be taken.

Gently apply pressure to blade by hand to

move open. Use Scotch Bright pad RED

07447 grade, wet with duck oil and clean

the damper internally at the point where

the blade closes. Wipe dry and leave

clean.

‘Massage’ exposed peripheral blade seal

until pliable.

10.1

Pre-check BEFORE power is established – Check the actuator voltage is

suitable for the application. 24V has a grey case, 230V has an orange case.

10.2

In accordance with BS9999 Annex W.1, inspections should be undertaken at

least annually, or more frequently where corrosive or dirty conditions prevail.

The maintenance log should be reviewed at each inspection and the

frequency adjusted as required dependent upon findings. (BSB also

recommend a maximum of 1 year between inspections which should start

more frequently initially and reduce frequencies only if conditions are proven

to allow).

10.3

Check damper is in its 'normal state'.

10.4

If damper is not in its 'normal state', refer to fault finding chart otherwise

continue.

10.5

As a pre-check BEFORE power is established – When the actuator

orientation has been changed or the actuator has been replaced, it should be

wound manually using the manual reset. If resistance is encountered – over-

winding can result in permanent damage to the damper which may invalidate

the warranty.

10.6

The actuator can be 'locked' open by winding manually with key provided,

then locked and also released by rotating the black lever (next to the golden

symbol) on face of actuator.

10.7

Switch to power to actuator. LED on TF will illuminate, and actuator will start

on travel to DRIVE-END position. After 60 seconds, visually check that

damper blade position and signaling corresponds.

10.8

IMPORTANT: Press and hold test switch button on the TF to allow damper

to travel to its closed position. Visually check that the damper blade position

and signal corresponds. (This is to ensure that the actuator functions

electrically and overrides the manual reset facility, should it have been used,

as it is feasible to leave the damper inadvertently reset without the TF being

functional if this test is not carried out)

10.9

Release TF button to allow damper to drive to normal position.

10.10 If damper has seized – Open the damper (even partially if possible). Clean

the inside of the damper case where the blade seals make contact. Use a

soft cloth with a light application of light lubricant (Connect Duck Oil

recommended). From the outside of the case, lightly apply a light lubricant

into blade axle bearings. Remove excess lubricant.

10.11 It is important to log, and review maintenance frequency based on

inspections and test history.

10.12 Use of heavy oils is not permitted, as this can lead to a build-up of dust/dirt

on damper surfaces.

10.13 The PML actuator is maintenance-free.

6

12