SETTING THE MIXTURE

Now that your engine is broken in, you can set the high and low speed

needle valves for optimum performance.

Note: Be careful to never lean the engine out too much. Remember

that the lubricants for your engine are suspended in the fuel. If you lean

out the fuel mixture too much you will also be lowering the amount of

lubricant entering your engine. Less lubricant means more chance of your

engine overheating and possible engine failure.

q

Setting the High Speed Needle Valve

q

1)

Start the engine and remove the power from the glow plug. Al-

low the engine to warm up for about 1 minute.

q

2)

After the engine has warmed up slowly lean the high speed mix-

ture until the engine reaches peak R.P.M. After reaching peak R.P.M. richen

the mixture slightly until an audible drop in R.P.M. is heard. If you are

using a tachometer this should be between a 200 - 300 R.P.M. drop.

o

3)

With the engine running at full power, carefully lift the nose of

the airplane about 45º into the air. The mixture should not become too

lean, but you may hear a slight increase in R.P.M. If the engine sags, or

loses R.P.M. when you hold the nose up, the mixture is too lean.

Note: R.P.M. will increase about 10% - 30% in the air. This is due to

the forward motion of the aircraft as it is flying. Because of this more air

is entering the carburetor, at a higher force, and causes the mixture to lean

out. Additionally, as the fuel level in the fuel tank goes down, fuel draw

becomes more difficult for the engine, especially during aerobatics, thus

causing the mixture to go lean. It is imperative that you set the mixture

rich while on the ground to compensate for the leaning tendencies that will

happen in the air. Always watch the exhaust during your flight. The en-

gine should leave a noticeable white smoke trail at all times. It there is no

smoke trail, the engine is running too lean. You should land immediately

and reset the mixture.

q

Setting the Low Speed Needle Valve

q

1)

Start the engine and lean out the high speed needle valve as per

the previous steps. Close the throttle until the slowest reliable idle is reached.

Allow the engine to idle for about 30 seconds.

q

2)

Quickly advance the throttle to full. If the engine just stops run-

ning as soon as the throttle is advanced, the idle mixture is too lean. With

the engine stopped, richen the idle mixture about 1/8 of a turn.

q

3)

Repeat steps # 1 and # 2 until the engine will transition from idle

to full throttle smoothly. Minor hesitation in the transition will be normal.

q

4)

If you quickly advance the throttle from idle to full and the en-

gine seems to be very rich during transition (i.e. lots of smoke coming

from the exhaust), the mixture is too rich. With the engine stopped, lean

the idle mixture about 1/8 of a turn.

q

5)

Repeat steps # 1 and # 4 until the engine will transition from idle

to full throttle smoothly. Minor hesitation in the transition will be normal.

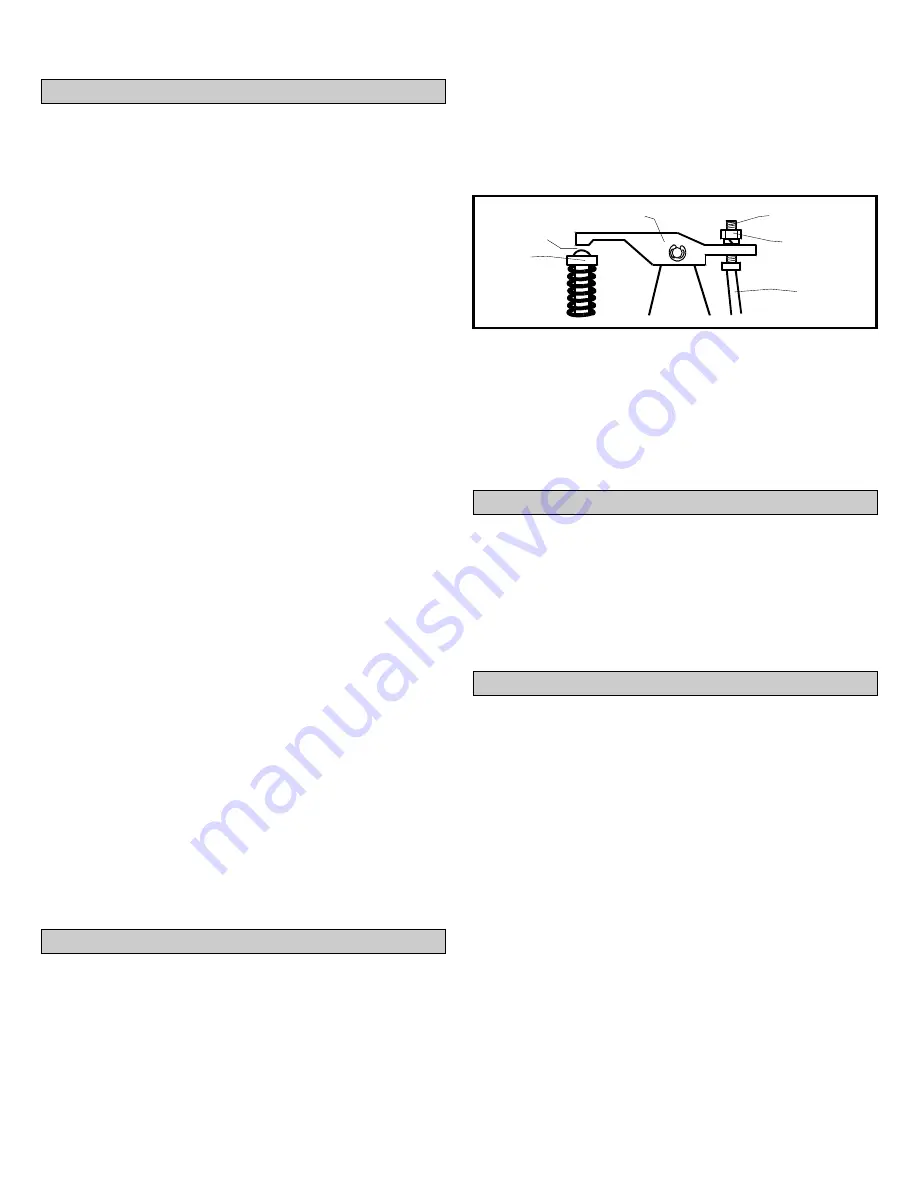

VALVE ADJUSTMENT

q

Adjusting the Valves

The Valve clearances are preset from the factory, but will require periodic

adjustment. Reset the valves after the first 1 hour of engine running. After

that, the valves can be checked and adjusted about every 8 hours of run-

ning. Some signs that the valves need adjusting are loss of power, rattling

sounds at low idle or if you have repaired the engine after a crash.

q

1)

With the engine cold, remove the rocker cover on top of the cyl-

inder head by unscrewing the two socket cap screws.

q

2)

Rotate the crankshaft until the piston is at top dead center. Both

valves are closed at this point.

q

3)

The required valve clearance is between .04mm and .10mm mea-

sured between the valve stem and the rocker arm. Use feeler gauges to

check the clearance. The .04mm gauge should pass through the gap with

only slight friction. The .10mm feeler gauge should be tight.

q

4)

Working with one valve at a time, loosen the lock nut using a

small wrench. Use a screwdriver and turn the adjustment screw counter-

clockwise about 1/2 turn. This will open the gap slightly. Slide the .04mm

feeler gauge between the rocker arm and the valve stem. Carefully turn the

adjustment screw clockwise until the rocker arm contacts the feeler gauge.

Using a small wrench, tighten the lock nut.

q

5)

Remove the feeler gauge and double check the gap. Repeat step

# 4 if necessary to achieve the correct setting. Repeat for the second valve.

SERVICE

All Magnum engines returned for warranty service must be within the warranty

terms as stated on the warranty card provided with your engine. Do not return the

engine to the place of purchase. They are not authorized or equipped to perform

warranty work on Magnum products. When requesting warranty service, please

observe the following:

F

Always send the complete engine including the carburetor and muffler. The

engine must be removed from the model.

F

Include a note detailing the problem or service you are requesting. Service

cannot be provided without this information. Include your daytime phone number

in the event we need more details pertaining to the service requested.

F

You may request an estimate of services at the time you return your engine for

service. An omission of this request implies permission for the Magnum Service

Center to service your engine at our discretion.

F

Include a method of payment for any service charges. If not specified, the unit

will be returned to you C.O.D.

F

Please include a check or money order in the amount of $6.50 to cover postage

and handling charges for the return of your engine. Do not send cash.

F

Send the engine to us by United Parcel Service, Federal Express or by Insured

Mail. Postage in not refundable. Send to:

Magnum Service Center

18480 Bandilier Circle

Fountain Valley, CA 92728

Phone (714) 963-0329

Fax (714) 964-6236

Email: [email protected]

MAINTENANCE

q

Avoid running the engine under dusty conditions.

q

At the end of every flying day, purge the engine of fuel by disconnect-

ing the fuel line and allowing the engine to run dry of fuel.

q

Use a high quality after run oil in the engine after you have purged the

engine of fuel. Inject the oil into the engine through the carburetor and

through the glow plug hole.

q

Wipe the outside of the engine dry using a soft cloth.

q

Use a fuel filter between the fuel tank and the carburetor.

Rocker

Arm

Valve

Stem

Pushrod

Lock Nut

Adjustment

Screw

Gap