PROPELLER, FUEL & GLOW PLUG

q

Propeller Recommendation

The diameter and pitch of the propeller needed for the XL 1.20RFS will

vary greatly depending on the application the engine is used in. The weight,

drag and the type of model and how you intend to fly it are all factors in

determining the correct size propeller to use. Experimentation will be nec-

essary to find the optimal size propeller for your particular application.

Ideally you want a propeller that the engine will turn in the 8,000 - 9,000

R.P.M. range, yet power the airplane sufficiently. Using a propeller that is

too small will cause the engine to run at too high an R.P.M. Using a pro-

peller that is too large will cause the engine run at too low an R.P.M. and

cause it to lug down too much. In both instances this can lead to premature

engine wear and eventual failure.

Propeller Size Recommendations

q

Engine Bolts and Firewall Requirements

The engine should be mounted to a heavy duty glass filled nylon or a metal

engine mount. Use only high quality steel cap screws and related hard-

ware to mount the engine to the motor mount. The firewall in the airplane

should be aircraft grade 5-ply plywood and be no less than 1/4” thick. The

firewall should also be reinforced to meet the torque and weight of the XL

1.20RFS engine.

q

Muffler and Exhaust Pipe Installation

The muffler threads onto an exhaust pipe, which then threads into the en-

gine head. First thread one cinch nut onto each end of the exhaust pipe.

Thread the muffler on one end. The

muffler should be threaded on at

least 1/4” to prevent vibration from

damaging the threads. Once you

have threaded the muffler onto the

exhaust pipe use an open end

wrench and tighten the cinch nut up

against the muffler. This will pre-

vent the muffler from loosening.

The exhaust pipe is adjustable to better match the scale appearance and

installation of your particular application. Thread the exhaust pipe into the

engine’s cylinder head. The pipe should be threaded in no less than 1/4”

to prevent vibration from damaging the threads. Once you have threaded

the exhaust pipe in place and into the proper position for your application,

use an open end wrench and tighten the cinch nut against the cylinder head.

This will prevent the exhaust pipe from loosening.

q

Tank Size and Orientation to Carburetor

Ideally the stopper in the fuel tank should be even with the high speed

needle valve or just slightly below the high speed needle valve. Most

models will only allow the fuel tank to be mounted higher than the ideal

location. A fuel tank that is positioned higher than the ideal location usu-

ally doesn’t pose any problem except when it is mounted excessively higher

and/or used in conjunction with an inverted mounted engine or during ex-

treme aerobatic flight. If mounting your engine inverted it is advised to

lower the fuel tank so the stopper is slightly below the high speed needle

valve. Doing this will prevent fuel from siphoning into the engine and

flooding it when the fuel tank is full. If you cannot lower the fuel tank far

enough, we suggest lowering it as far as can be allowed in your particular

application.

The size of the fuel tank used should be 12oz. - 16oz. depending on

the model and the length of flights desired. Use of a 16oz. tank will pro-

vide between 15 - 20 minutes of run time at full throttle. Use of a fuel tank

any larger than 16oz. can lead to excessive leaning of the engine during

flight and is not recommended.

q

Carburetor Orientation

In some cases the particular installation of the engine in your model may

make it necessary to change the position of the carburetor. You may want

the throttle arm on the opposite side

than how it comes preinstalled. You

can remove the carburetor and re-

install it in the opposite direction

with no effect on performance. To

remove the carburetor loosen the

two screws holding the intake mani-

fold in place. Next, remove the two

screws holding the choke assembly/

carburetor to the engine. Remove the carburetor by gently pulling it down

off the intake pipe. To reinstall the carburetor reverse the process. We

highly recommend applying machine oil to the o-ring inside

the carburetor mounting base and on the carburetor mounting flange on the

intake pipe. This will prevent the o-ring from being inadvertently cut when

reinstalling the carburetor.

q

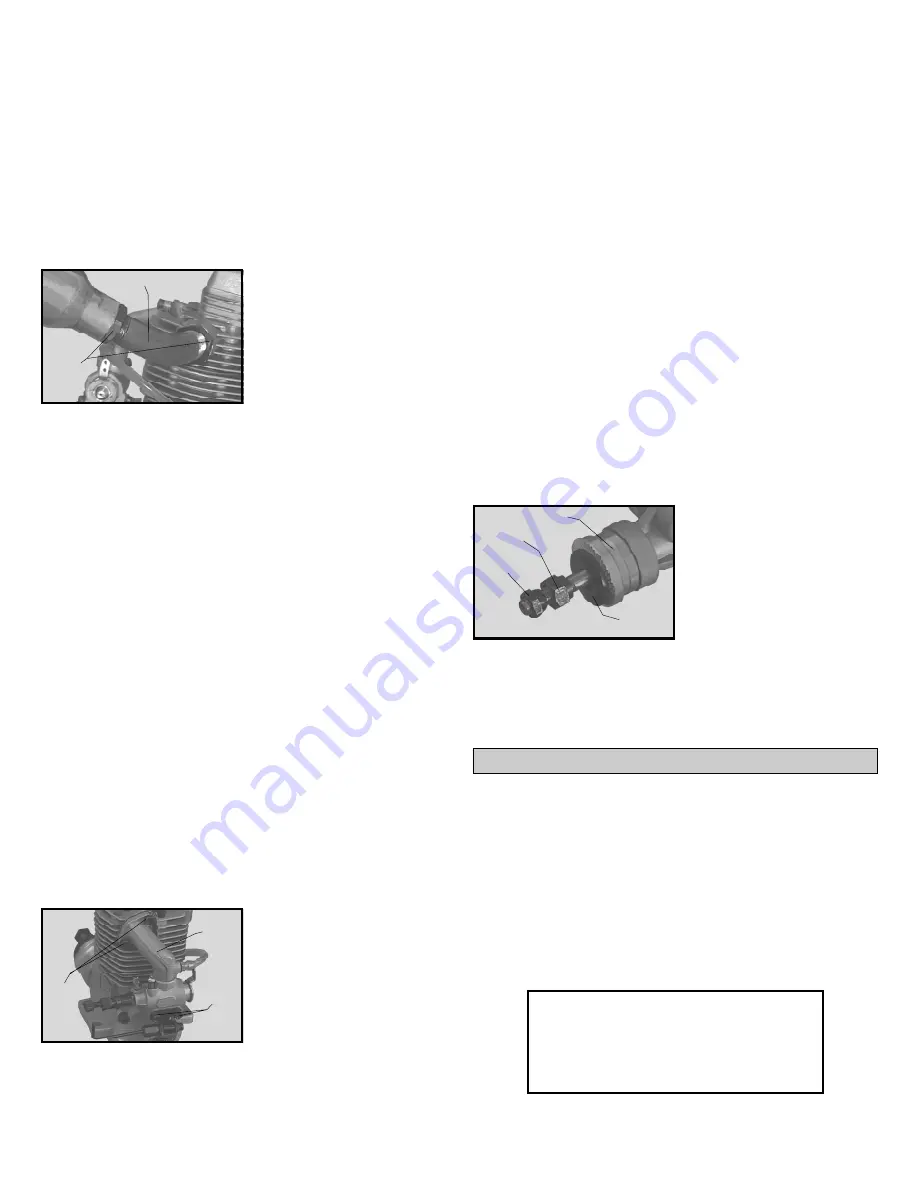

Needle Valve Extension

If an extension is required to adjust the high speed needle valve, use a

1.5mm diameter wire of the necessary length. Loosen the set screw in

the side of the needle valve, insert the wire into the end of the needle

valve and tighten the set screw firmly. If the extension is more than 3”

long we recommend supporting the outer end of the extension to prevent

excessive vibration.

q

Propeller Installation

Your engine comes equipped with a main propeller nut and one safety nut.

For your safety, we recommend using both the propeller nut and the safety

nut to secure the propeller in place.

Note: Before installing any propeller it must be properly balanced.

Running an engine, especially of this size, using an improperly balanced

propeller can lead to excessive vibration causing excessive stress and wear

on both the engine and the airframe. Balance the propeller using the recom-

mended method of the propeller manufacturer. Several products are avail-

able to properly balance propellers. Ask your local retailer for more infor-

mation about these items.

Using a 5/16” drill bit or a prop reamer, drill out the hole in the propeller

hub to fit the crankshaft. The crankshaft is 5/16” in diameter. Slide the

propeller onto the crankshaft, up against the thrust washer. Slide the pro-

peller washer up against the propel-

ler. Thread the prop nut onto the

crankshaft. Notice that the prop nut

has a flange on the back of it. This

flange fits inside the washer. Com-

pletely tighten the prop nut to se-

cure the propeller in place. Install

the safety nut onto the crankshaft

then tighten it against the prop nut.

When tightening the prop nut and

safety nut, use the proper size open end wrench. Do not use pliers.

Note: If you are installing a spinner onto your engine the cone of the

spinner must not rub against the propeller. If the spinner cone rubs against

the propeller this could lead to propeller damage and eventual propeller

failure.

15 x 6

15 x 8

15 x 10

16 x 6

16 x 8

Use 15 x 6 for initial break-in procedures

Muffler

Exhaust Pipe

Cinch

Nuts

Loosen

Intake

Pipe

Remove

Thrust Washer

Prop Nut

Safety

Nut

Prop Washer