;;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;;

5

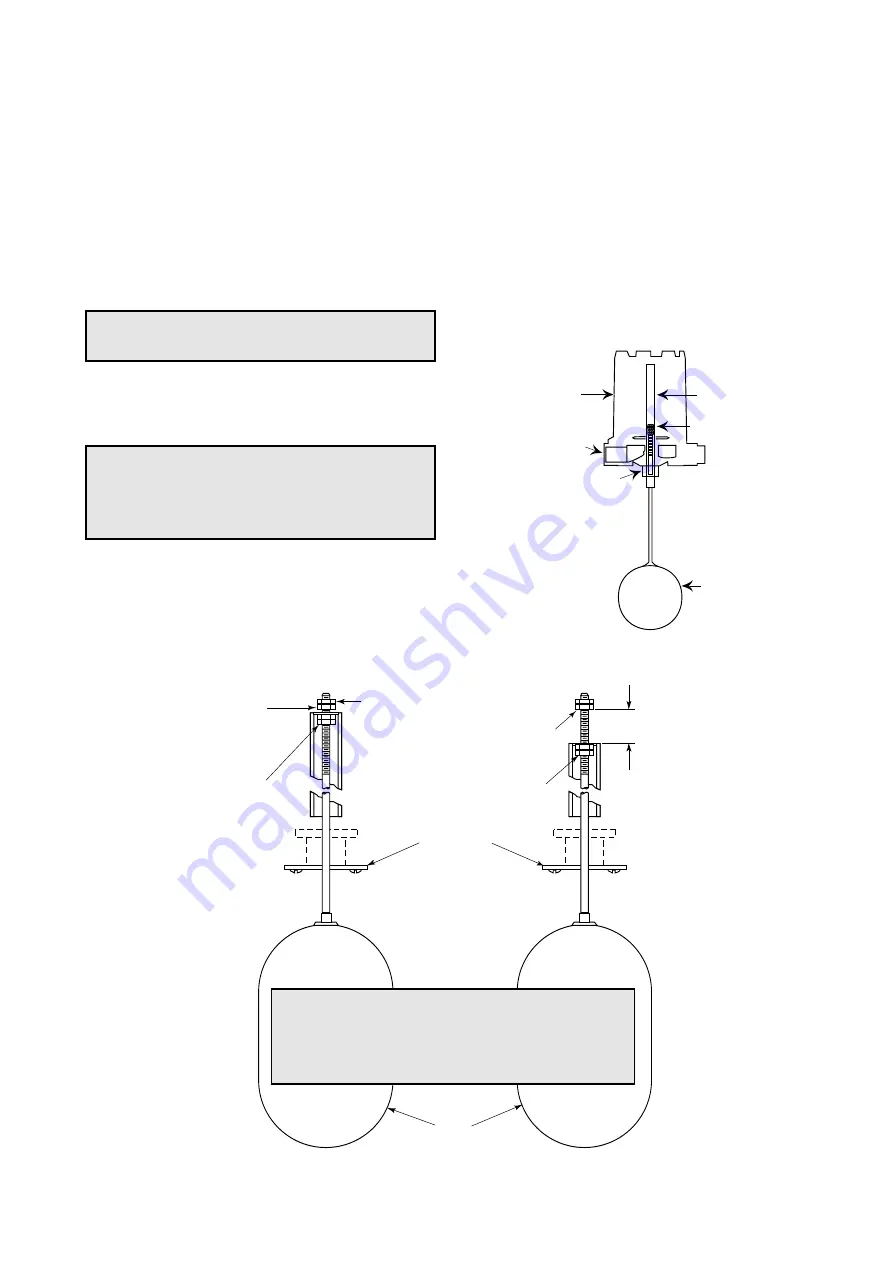

Figure 4

Normal Factory Setting

(minimum differential)

Figure 5

Differential adjustment

Figure 3

SWITCH DIFFERENTIAL ADJUSTMENT

The standard dif

ferential of T20 and T21 Liquid Level

Switches may be field adjusted. Adjustment may be nec-

essary if a wider differential needs to be set to overcome

switch chatter caused by the process.

The differential, or the amount of level travel between

switch-on and switch-off, may be adjusted by repositioning

the lower jam nuts on the float stem. The standard factory

setting is for a minimum amount of play (gap) between the

top jam nuts and the attraction sleeve as shown in

Figure

4

.

NOTE:

For assistance in computing level dif

ferential

change for a specific control, consult the factory giving the

model and serial numbers of the control.

NOTE:

T

o widen the differential 13 mm (0.5"), the lower

jam nuts must be set proportionately lower on the stem (i.e.

in this example 13 mm (0.5")).

1. Determine what change in differential is necessary.

2. Make sure power source is turned off.

3. Unscrew and remove switch housing cover.

4. Disconnect power supply wires from switch mecha-

nism. Pull wires out of conduit connection opening in

housing base. Refer to

Figure 3

.

5a. Perform system shut-down procedures as required to

relieve pressure from tank or vessel and drain off liquid

head, if required. Allow unit to cool.

5b. The amount of level travel between switch-on and

switch-off actuations (differential) may be field adjusted

by repositioning the lower jam nuts on the float stem.

The standard factory setting is for a minimum amount

of play (gap) between the top jam nuts and the attrac-

tion sleeve, as shown in

Figure 4

. This setting may be

increased to a maximum of 13 mm (0.50"), as shown

in

Figure 5

.

6. Remove switch housing assembly by loosening hex

nut, which is located immediately below housing base.

Refer to

Figure 3

.

CAUTION:

Maximum differential adjustment is 13 mm

(0.5").

CAUTION:

Before attempting any work on the control,

pull disconnect switch, or otherwise assure that electri-

cal circuit(s) through the control is deactivated. Close

operating medium supply valve on controls equipped

with pneumatic switch mechanisms.

Switch housing

cover

Slight play (gap)

must be allowed

(0.8 mm (.03") typical)

Position of bottom jam

nuts (normal factory

setting)

For access to bottom jam

nuts, mark position,

remove top jam nuts,

washer, and attracting

sleeve

Maximum gap setting

(Applies to models having

a single switch mechanism

with a single magnet

actuator only)

Replace in

same position

Drop bottom jam nuts to

increase gap setting

(see instructions below)

Sleeve stop

strap

Float

13 mm

(0.50")

Cable connexion

Enclosing tube nut

Enclosing tube

Housing base

Float

Refer to Figures 4 and 5

CAUTION:

After increasing gap setting, be certain to

check for proper operation of switch mechanism by rais-

ing and lowering float assembly. Magnet must snap clean-

ly, with additional float movement available after magnet

snaps.