6

SWITCH DIFFERENTIAL ADJUSTMENT (cont.)

PREVENTIVE MAINTENANCE

NOTE: Use a new enclosing tube gasket when reassem-

bling enclosing tube to the chamber. Coat enclosing tube

threads with “anti-seizing” compound.

13. Replace enclosing tube, switch, and base on chamber.

Screw tube clockwise until tightened to 10,42 -

13,90 kgm of torque.

14. Rotate switch housing to correct position and tighten

set screw at base of switch housing. See Figure 4.

15. Bring supply wires through conduit outlet. Follow steps

5 through 10 of the “Wiring” section on page 4.

NOTE: If switch mechanism fails to function properly, check

vertical alignment of control housing and consult

installation bulletin on switch mechanism. If the unit still

fails to function properly, consult the factory.

HIGH LEVEL CONTROLS

On high level controls, the switch trips on the higher actua-

tion point and resets on the lower actuation point.

CAUTION:

On high level controls, widening the differential

requires raising the trip point a proportionate

amount. The reset point will remain the same.

To widen the differential by raising the trip point, follow

steps 1 through 16 under “Low Level Controls”.

Switch

housing

cover

Conduit

connection

Enclosing

tube nut

Enclosing tube

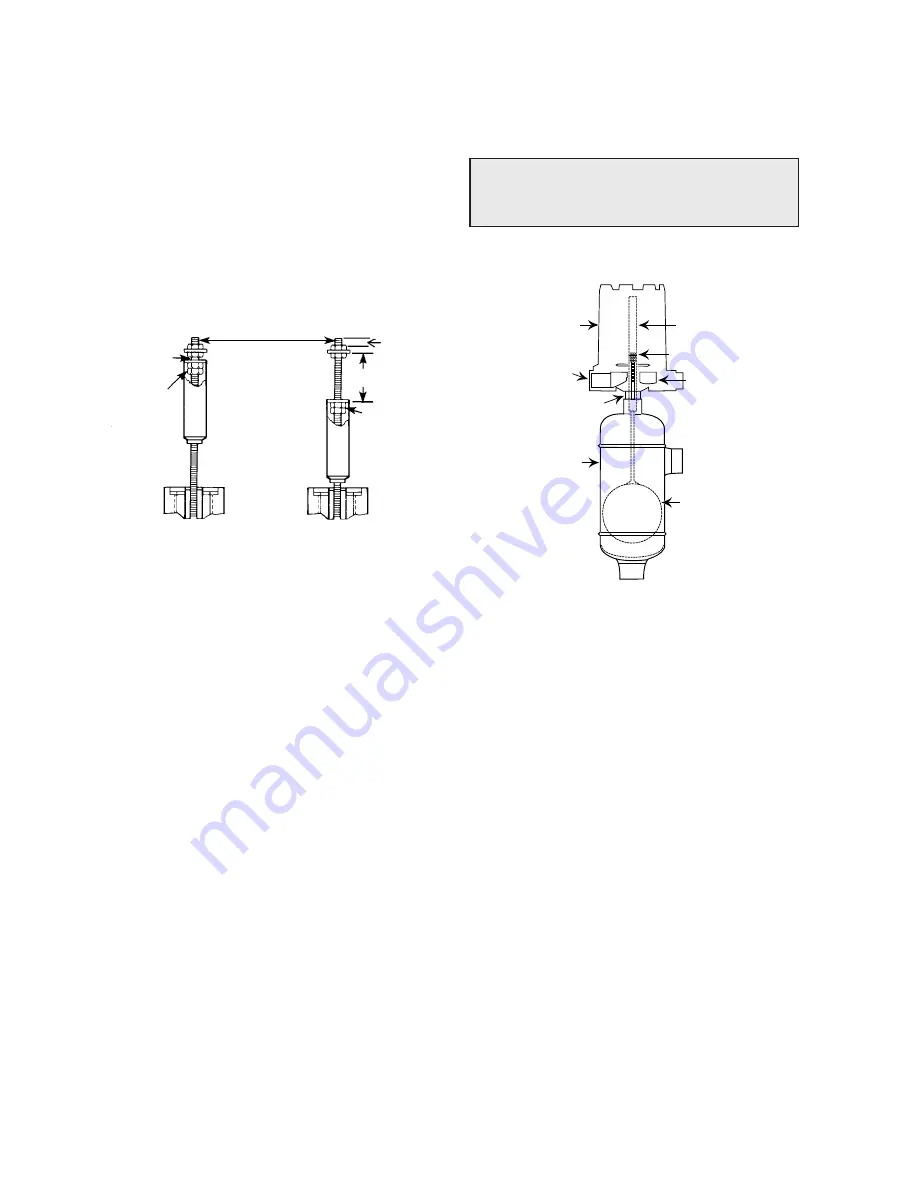

See figures 6 and 7

Housing base

Float

Chamber

Figure 5

Slight play (gap)

must be allowed

(0.8 (0.03") typical

Position of bottom

jam nuts (normal

factory setting)

Replace in same position

Distance

Drop bottom

jam nuts to

increase gap

setting (see

instructions

above)

Maximum gap setting

(applies to models having

a single switch mecha-

nism with a single magnet

actuator only!)

CAUTION: After increasing

gap setting, be certain to

check for proper operation of

switch mechanism by raising

and lowering float assembly.

Magnet must 'snap' cleanly

with additional float movement

available after magnet snaps.

25 (1")

Normal factory setting

(minimal differential)

Figure 6

Differential adjustement

Figure 7

Periodic inspections are a necessary means to keep your Magnetrol level control in good working order. This control

is, in reality, a safety device to protect the valuable equipment it serves. Therefore, a systematic program of "preven-

tive maintenance" should be implemented when control is placed into service. If the following sections on "what to

do" and "what to avoid" are observed, your control will provide reliable protection of your capital equipment for many

years.

WHAT TO DO

1. Keep control clean

NEVER leave switch housing cover off the control. This

cover is designed to keep dust and dirt from interfering

with switch mechanism operation. In addition, it protects

against damaging moisture and acts as a safety feature

by keeping bare wires and terminals from being

exposed. Should the housing cover become damaged or

misplaced, order a replacement immediately.

2. Inspect switch mechanisms, terminals and connec-

tions monthly.

– Mercury switches may be visually inspected for short

circuit damage. Check for small cracks in the glass

tube containing the mercury. Such cracks can allow

entrance of air into the tube causing the mercury to

"oxidize". This is noticeable as the mercury will appear

dirty and have a tendency to "string out" like water,

instead of breaking into round pools. If these condi-

tions exist, replace the mercury switch immediately.

– Dry contact switches should be inspected for exces-

sive wear on actuating lever or misalignment of

adjusting screw at point of contact between screw

and lever. Such wear can cause false switch actuat-

ing levels. Adjust switch mechanism to compensate

(if possible) or replace switch.

Do NOT operate your control with defective or malad-

justed switch mechanisms (refer to bulletin on switch

mechanism furnished for service instructions).

– Magnetrol controls may sometimes be exposed to

excessive heat or moisture. Under such conditions,

insulation on electrical wires may become brittle,

eventually breaking or peeling away. The resulting

"bare" wires can cause short circuits.

Check wiring carefully and replace at first sign of brittle

insulation.

– Vibration may sometimes cause terminal screws to

work loose. Check all terminal connections to be cer-

tain that screws are tight. Air (or gas) operating medi-

um lines subjected to vibration may eventually crack

or become loose at connections causing leakage.

Check lines and connections carefully and repair or

replace, if necessary.

– On units with pneumatic switches, air (or gas) operat-

ing medium lines subjected to vibration, may eventu-

ally crack or become loose at connections carefully

and repair or replace, if necessary.

NOTE: As a matter of good practice, spare switches should

be kept on hand at all times.

3. Inspect entire unit periodically

Isolate control from vessel. Raise and lower liquid level

to check for switch contact and reset.

Summary of Contents for 075

Page 13: ...13 ...