Interconnections

30

Encoder

The HPV 900 Series 2 can be configured for

an incremental two-channel quadrature

encoder. The drive’s encoder circuitry

incorporates resolution multiplication and

complimentary outputs. It is recommended that

a diferential line driver encoder of type 7272 is

used. Push-pull type encoders can be used but

only for TerMag boards at 46S04284-1020.

See appendix Selecting and Mounting of

Encoder page 187.

Incremental Encoder Wiring

Use twisted pair cable with shield tied to

chassis ground at drive end, in order to

minimize magnetic and electrostatic pick-up

current and to minimize radiated and

conducted noise.

Reasonable care must be taken when

connecting and routing power and signal

wiring. Radiated noise from nearby relays

(relay coils should have R/C suppressors),

transformers, other electronic drives, etc. may

be induced into the signal lines causing

undesired signal pulses.

Power leads and signal lines must be routed

separately. Signal lines should be shielded,

twisted and routed in separate conduits or

harnesses spaced at least 12 inches apart

from power wiring. This protects the cable from

physical damage while providing a degree of

electrical isolation. Also, do not run cable in

close proximity to other conductors, which

carry current to heavy loads such as motors,

motor starters, contactors, or solenoids. Doing

so could result in electrical transients in the

encoder cable, which can cause undesired

signal pulses. Power leads are defined as the

transformer primary and secondary leads,

motor leads and any 120 VAC or above control

wiring for relays, fans, thermal protectors, etc.

Continuity of wires and shields should be

maintained from the encoder through to the

controller avoiding the use of terminals in a

junction box. The shield and shield drain wires

must be insulated from other objects. This

helps to minimize radiated & induced noise

problems and magnetically induced ground

loops.Always use an encoder with

complementary output signals. Connect with

twisted-pair shielded wire so that wire-induced

currents will self-cancel.

NOTE: DO NOT ground the encoder through

both the machine and the cable wiring.

Connect the shield at the receiver device only.

If the shield is connected at both ends, noise

currents will flow through the shield and

degraded performance will result. HPV 900

Series 2 Incremental Encoder Specifications

The HPV 900 Series 2 requires the use of an

encoder coupled to the motor shaft. The

encoder power can be either a 5VDC or

12VDC supply. The capacity of each power

supply is the following:

supply voltage:

12VDC

200mA capacity

supply voltage:

5VDC

400mA capacity

The HPV 900 Series 2 can accept encoder

pulses of:

500 to 10,000 pulses per revolution (ppr)

a maximum frequency of 300kHz

IMPORTANT

Motor phasing should match the encoder

feedback phasing. If the phasing is not

correct, the motor will not accelerate up to

speed. It will typically oscillate back and forth

at zero speed, and the current will be at the

torque limit. Swapping A and /A or switching

two motor phases should correct this situation.

The encoder pulses per revolution must be

entered in the ENCODER PULSES parameter,

see Drive A1 Submenu on page 40

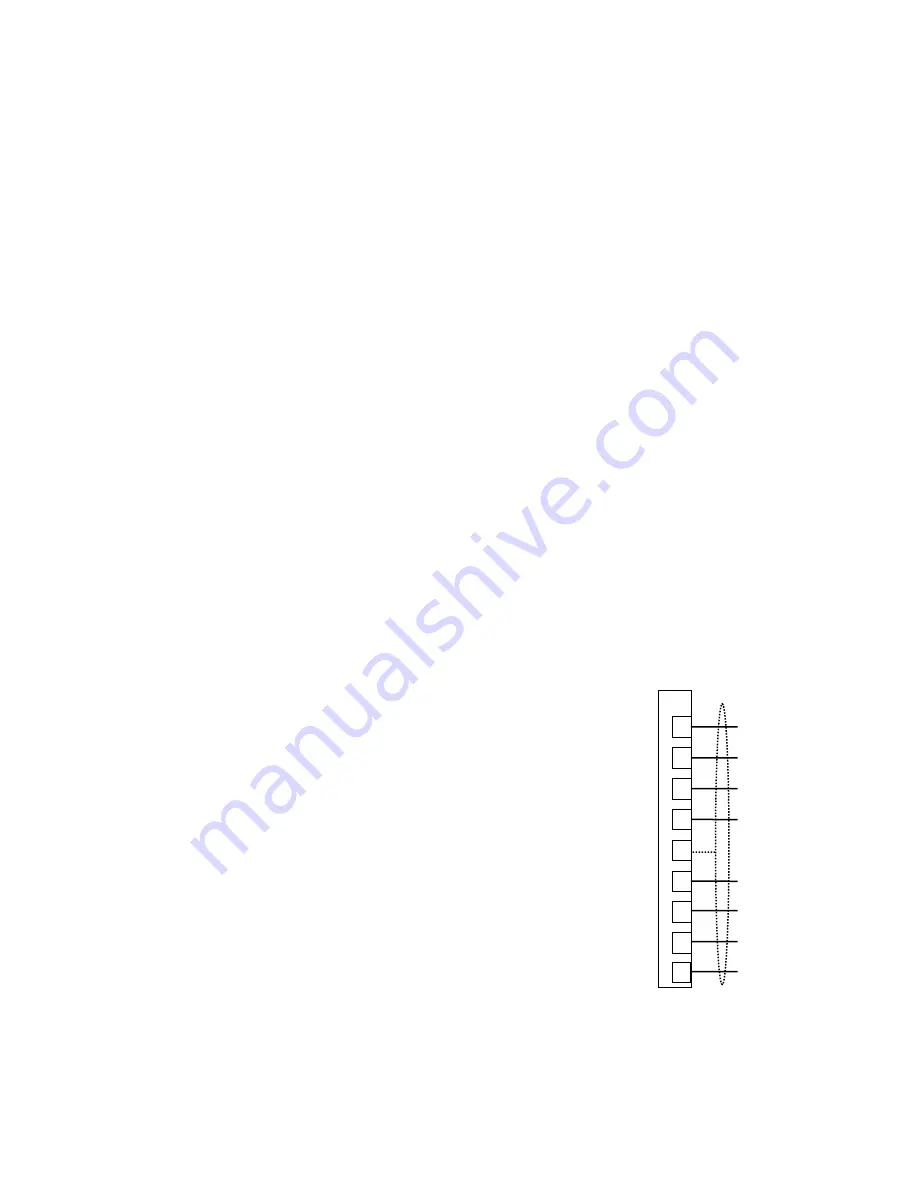

The encoder connection terminals are shown

in Figure 18.

Figure 18: Encoder Connections

As a reference, please refer to the table below

if replacing an HPV900 or HPV600 with the

HPV900 Series 2 drive.

1

2

3

4

5

17

18

19

A

/A

B

/B

shield

e5/12VDC power

encoder common

Z

TB1

20

/Z