10

and arc voltage settings cause the electrode to

intermittently short-circuit with the weld pool

at a controlled frequency. Metal is transferred

by the wire tip actually dipping into the weld

pool and the short-circuit current is sufficient

to allow the arc to be re-established. This short-

circuiting mode of metal transfer effectively

extends the range of MIG welding to lower

currents so thin sheet material can readily

be welded. The low heat input makes this

technique well-suited to the positional welding

of root runs on thick plate, butt welds for

bridging over large gaps and for certain difficult

materials where heat input is critical. Each

short-circuit causes the current to rise and the

metal fuses off the end of the electrode. A high

short-circuiting frequency gives low heat input.

Dip transfer occurs between ±70-220A, 14–23

arc volts. It is achieved using shielding gases

based on carbon dioxide and argon.

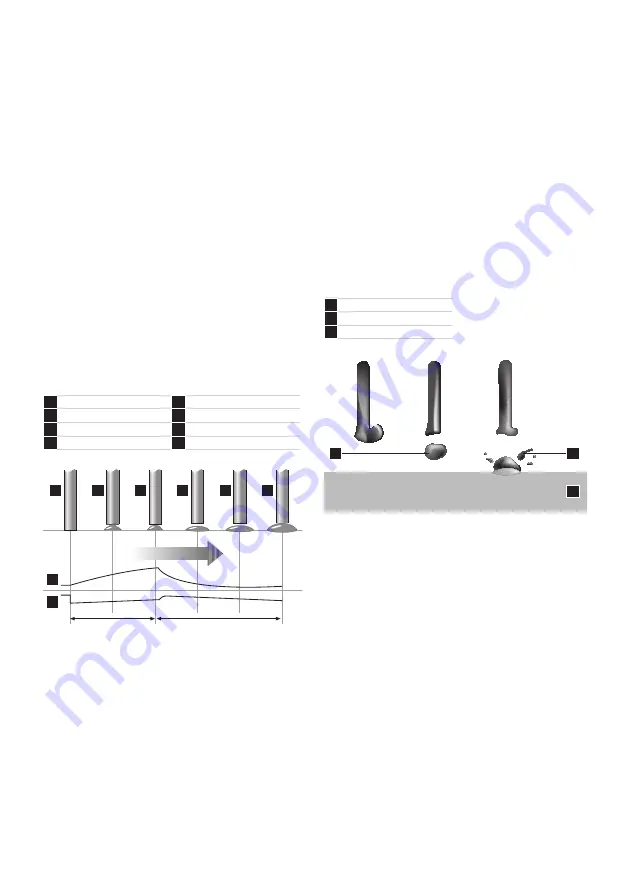

1

Short circuit

5

Arc gap shortens

2

Necking

6

Short circuit

3

Arc re-ignition

7

Current (A)

4

Arc established

8

Voltage (V)

1

2

6

3

4

5

Time

Short circuit cycle

Arcing cycle

7

8

Schematic of Dip Transfer

Metal-cored wires transfer metal in dip mode

at low currents just like solid MIG wires. This

transfer mode is used for all positional work

with these types of wire.

Globular Transfer

Metal transfer is controlled by slow ejection

resulting in large, irregularly-shaped ‘globs’

falling into the weld pool under the action of

gravity. Carbon dioxide gas drops are dispersed

haphazardly. With argon-based gases, the

drops are not as large and are transferred

in a more axial direction. There is a lot of

spatter, especially in carbon dioxide, resulting

in greater wire consumption, poor penetration

and poor appearance. Globular transfer occurs

between the dip and spray ranges. This mode

of transfer is not recommended for normal

welding applications and may be corrected

when encountered by either decreasing the arc

voltage or increasing the amperage. Globular

transfer can take place with any electrode

diameter.

1

Large droplet

2

Splatter

3

Workpiece

1

2

3

Schematic of Globular Transfer

Basic flux-cored wires tend to operate in a

globular mode or in a globular-spray transfer

mode where larger than normal spray droplets

are propelled across the arc, but they never

achieve a true spray transfer mode. This transfer

mode is sometimes referred to as non-axial

globular transfer.

Self-shielded flux-cored wires operate in a

predominantly globular transfer mode although

at high currents the wire often ‘explodes’

across the arc.

Spray Transfer

In spray transfer, metal is projected by an

electromagnetic force from the wire tip in

the form of a continuous stream of discrete

droplets approximately the same size as the