Page 10 of 18

508196-01

Issue 2120

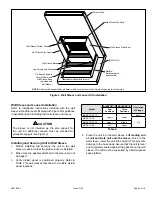

Ventilation Air (CFM) *

Cumulative

Knockouts

Removed

Total External Static Pressure

( return) **

0.1

0.2

0.3

0.4

0.5

0.75, 1.0, 1.5

TON

# 1 Only

7

9

12

15

18

#1 thru #2

10

15

20

24

28

#1 thru #3

12

18

25

32

38

#1 thru #4

18

28

36

45

54

#1 thru #5

23

35

46

57

69

#1 thru #6

27

41

54

67

80

#1 thru #7

32

48

63

78

93

#1 thru #8

37

55

73

90

107

#1 thru #9

41

61

80

100

118

2.0, 2.5, 3.0

TON

# 1 Only

21

20

19

17

16

#1 thru #2

28

27

25

24

22

#1 thru #3

35

33

32

30

28

#1 thru #4

45

42

40

38

35

#1 thru #5

55

52

49

46

43

#1 thru #6

66

62

59

55

52

#1 thru #7

79

75

71

66

62

#1 thru #8

91

86

81

76

71

#1 thru #9

105

99

94

88

82

* Assumes proper speed tap adjustments to maintain nominal supply air CFM

** Assumes equal supply and return static pressures

Table 6.

Ventilation

Air (CFM

)

Cumulative Knockouts Removed

0

10

20

30

40

50

60

70

80

90

100

110

120

1

2

3

4

5

6

7

8

9

0.75, 1, 1.5 Ton .225'' Supply & .225''

Return, .45'' Total Duct Static

2, 2.5, 3 Ton .225'' Supply & .225''

Return, .45'' Total Duct Static

Figure 9. Ventilation Air CFM

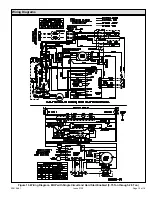

Thermostat

The room thermostat should be located on an inside

wall where it will not be subject to drafts, sun exposure,

or heat from electrical fixtures or appliances. Follow

manufacturer’s instructions enclosed with the thermostat

for general installation procedures. Color-coded insulated

wires (#18 AWG) should be used to connect the thermostat

to the unit.

Electrical Connections

The unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

or CSA C22.2 Part 1 (latest edition). Any alteration of

internal wiring will void certification and warranty.

Units are factory wired for a 230 volt power supply. If power

supply is 208 volts, it will be necessary to change a wire

connection on unit transformer from 240 volt terminal to

208 volt terminal as shown on the wiring diagram.

Use wiring with a temperature limitation of 75°F minimum.

Run the 208 or 230 volt, single phase, 60 hertz electric

power supply through a fused disconnect switch to the

control box of the unit and connect as shown in the unit’s

wiring diagram.

The power supply to the unit must be NEC Class 1 and

must comply with all applicable codes. A fused disconnect

switch should be field provided for the unit, and must be

separate from all other circuits. If any of the wire supplied

with the unit must be replaced, replacement wire must be

of the type shown on the wiring diagram.

Electrical wiring must be sized to minimum circuit ampacity

(MCA) marked on the unit.

Use copper conductors only

.

Each unit must be wired with a separate branch circuit and

be properly fused.

NOTE:

Some models require two separate power supply

circuits. See the unit wiring diagrams and rating plates for

specifications.