Page 5

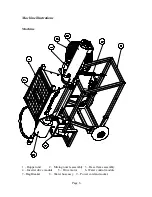

Section 2 - Machine Description

Function

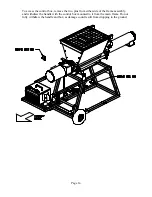

The continuous mixer uses pre-bagged, pre blended material, that is broken via the bag

breaker on the hopper, and poured into the hopper, that then discharges into the nozzle

and mixes it with water, to provide a usable mixture at its outlet.

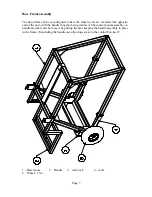

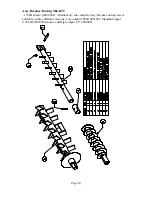

The machine has a drive motor, that turns a drive shaft within a material hopper that in

turn rotates a helical feed screw, in turn rotating a mixing shaft. The combination of these

shafts and mixing components move material from the hopper through to the mixing

nozzle, that with the addition of an adjustable water control that hydrates the mixture to

the desired level. The mixing tines in the nozzle tube, mix and shear the material so that

once it emerges from the discharge aperture, the mixture is correctly mixed and sheared

ready for use or for pumping to the application.

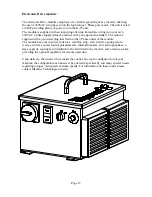

The machine is driven by an electric motor powered by 220VAC 3 phase 60/50Hz, via

an electronic variable speed inverter supplied by two phase 208VAC 60 Hz, or 220/240

VAC 50/60Hz, or 440/480 VAC 60Hz 3phase. Input power

The inverter control box allows the user to adjust the speed of rotation and in turn the

volumetric displacement per rev of the feed screw, to provide the require “flow” of

material. The control box also contains control for a water valve that operates when the

unit is started in the “feed” direction. If the unit is reversed for any reason the water will

turn off, and then turn back on once the reverse knob is released.

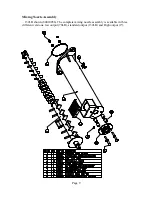

The continuous mixer is fitted with a water control assembly, that contains a pressure

regulator, a control valve and a visual water flow meter. The flow of water out of the

flow meter into the mixing nozzle is adjustable via the control knob at its base. Turning

clockwise slows the flow rate, counter clockwise increases the flow.

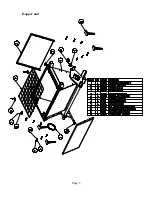

The difference between the machines is primarily the material dosing rate, which is

controlled by the dosing screw. There are three styles of dosing screw available, a “132

lb” a “78 lb” and a “2””, the differences in the screws being the pitch.