Page 28

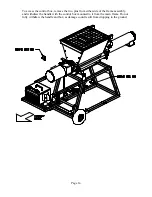

Section 5 – Machine operation / speed setting

The continuous mixer will discharge approx 132 LBS (78 LBS) of course grain sand

@280 RPM Max RPM, with the knob at half scale the RPM will be 140 and the delivery

approx 66 LBS (39 LBS).

The following are to be completed by trained and experienced persons, familiar with the

mixing system provided.

1. Fill the D-25 hopper with material. By dropping bags over the bag breaker,

twisting left and right by approx 15 degrees, then lifting both ends of the bag to

tear it in the middle. Allow the material to drop into the hopper, then remove the

bag from the grid area into a disposal container.

2. Turn the water supply OFF and establish the speed the mixer should run, by either

measuring the output within a certain time, or by weighing the output within a

certain time.

3. Turn ON the water supply, and disconnect the hose to the mixing nozzle. Place

the hose end on the ground where water will not damage anything.

4. Hang a bucket on the end of the mixing nozzle to catch material.

5. Turn the machine ON in the FWD direction and observe water to flow through the

meter. Quickly set the water flow to suit the amount of material being delivered

(base mix ration on manufacturers information). STOP the machine.

6. Remove the bucket and return the contents to the hopper. Reconnect the hose to

the mixing nozzle.

7. The machine is now ready for use.

General notes for operation

Turn main power switch on.

Push start button.

Adjust speed to desired output.

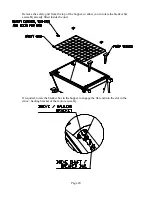

Do not let hopper run below the top of the mixing shaft while mixing or the mix rations

will change.

To stop machine push the stop button.

When cleaning the mixer, do not remove grate while mixer is running.

Do not spray water on or in control box. Control box should be wiped down with a damp

rag.

If access is required in to the hopper, disconnect power source before removing grate.

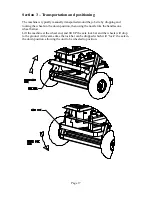

Mixer can be disassembled by removing wedges, this facilitates easier transport and final

clean up.

Always check hoses and cords for wear.

The unit runs on high voltage and is capable of high torques.

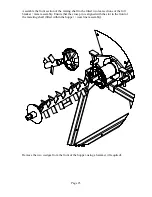

Ensure that, after every 3 hours of operation, that the nozzle is removed together with the

mixing shaft for cleaning. Check that the feed screw section of the shaft (in the hopper) is

cleaned at the end sticking from the hopper as this is prone to water contamination, and

can suffer a material build up.