Move the stem of the cylinder 124 forward to the mobile vice group (button ) and fix the stem to it with

the nut 159. Fix the cylinder with the four screws, first switch off and then switch on the machine for the zero setting.

F. CUTTING COOLANT

For the cooling of the circular blade, fill the tank with emulsible oil obtained from a mixture of water and AGIP AQUAMET

700 EP oil with a percentage of 5-7%

8. MACHINE START UP AND OPERATION

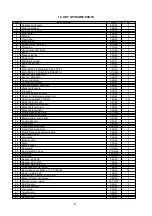

8.1 DEVICES AND THEIR LOCATION

(The location of the devices described is shown on the SPECIAL 380 A installation plan Draw.4 Encl. 2)

Code

200

LOCKABLE MAIN SWITCH

Code

115

ELECTRIC PUMP

Code

112

EMERGENCY BUTTON

Code

123

ROLLER CONVEYOR

Code

62

LOCKING VICE

Code

114

BAR-STOP

Code

85

VICE CYLINDER

Code

97

CYLINDER FOR LIFTING BOW

8.2 TOOLS SUPPLIED

1

Allen wrench size 3

1

Allen wrench size 5

1

Allen wrench size 6

1

Allen wrench size 8

1

Allen wrench size 10

8.3 OPERATION

CHECKS TO CARRY OUT BEFORE EACH CUT

A. Tension the band by rotating the handwheel 56 till the end of the traverse. On the display does not blink the signaling

“Broken Blade”. Remember at the end of the operation to loosen the hand wheel to avoid the slackening of the band.

B. Check that the hand indicates the required cutting angle (vice scale).

C. Make sure that the bow and the vice are locked by means of the lever 63 (DRAW. 8 ENCL. 3).

D. Adjustment of bow-stroke: the two cutting stopsare made up of two limit switches located on the bow support arm 59.

To adjust the upper stop position the bush 83 on the upper limit switch. For the lower stop adjust the bush 84.

E. Make sure that the piece to be cut is properly secured in the vice;

F. Make sure that the cooling liquid is circulating in the machine. Use the taplocated on the guide shoe to regulate the

flow of liquid.

G. When starting the motor, make sure that the band rotates in the direction of the arrow shown in Draw. 3-4-5 Encl.3.

H. To obtain maximum cutting accuracy, the unit must be located the nearest possible to the workpiece. Clamp

the work piece with the vice, release the

m

obile blade guide plate 32 with screw and move it near the vice jaw so

that it doesn’t touch it during the cutting operation, then secure it again. When carrying out this operation, make

sure that the blade guide guard does not come out of the bow guard leaving a part of the blade exposed.

CUTTING OPERATION

A. Before cutting, check that the inclination is the one required. In order to correct or change the inclination, place the

bench lever 63 in position B (DRAW. 4 ENCL. 2) and after correction, move it back to position A.

B. For other information regarding the cutting operation and machine programming, follow the supplied MACC4

instructions carefully.

C. To replace the band, carry out the same operations used to assemble the band (chapter 7c).

D. For the choice of blade see table DRAW 1 ENCL.1.

ATTENTION!!!

-W

E STRONGLY DISCOURAGE THE USE OF BLADES WITH RUINED OR INSUFFICIENTLY SHARP CUTTING EDGES

.

-I

T IS NOT POSSIBLE TO CUT AT

60°

ON MACHINE WITH VERTICAL PRESSING DEVICE

.

-O

N MACHINE WITH HYDRAULIC VERTICAL PRESSING

,

REMOVE THE ROLLER DEVICE FOR THE FRONT PACK CUTTING BEFORE MAKING

CUTS AT

45°

-R

EMOVE THE CHUTE FOR CUTS OVER

45°

-F

OR CUTTINGS GREATER THAN

550

MM

. ,

IT IS NECESSARY TO REMOVE THE REAR MOBILE ROLL OF THE CARRIAGE

8.4 SPECIAL SAFETY CHECKS

A. Before using the machine, check carefully that the safety devices are in good working order, that the mobile parts

are not blocked, that no parts are damaged and that all the components are installed correctly and are functioning

properly.

4

Summary of Contents for SPECIAL 380 A

Page 1: ... 2 ...

Page 2: ......

Page 4: ......

Page 5: ... ...

Page 6: ......

Page 7: ......

Page 8: ......

Page 20: ...12 ...

Page 21: ... 0 1 2 2 3 2 4 5 2 6 7 8 5 2 97 8 2 4 0 6 4 1 6 4 4 0 1 88 3 1 0 A 6 4 4 4 4 5 ...

Page 26: ... 4 N 2 N N 2 N LN 2 L N LN 2 L N N N 7 3 7 7 3 7 A L 2 2 2 2 O 0 L L 7 3 7 7 3 7 A L 2 2 2 2 ...

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ... ...