139-0647-01.21

21

Chapter Five--Control Setup

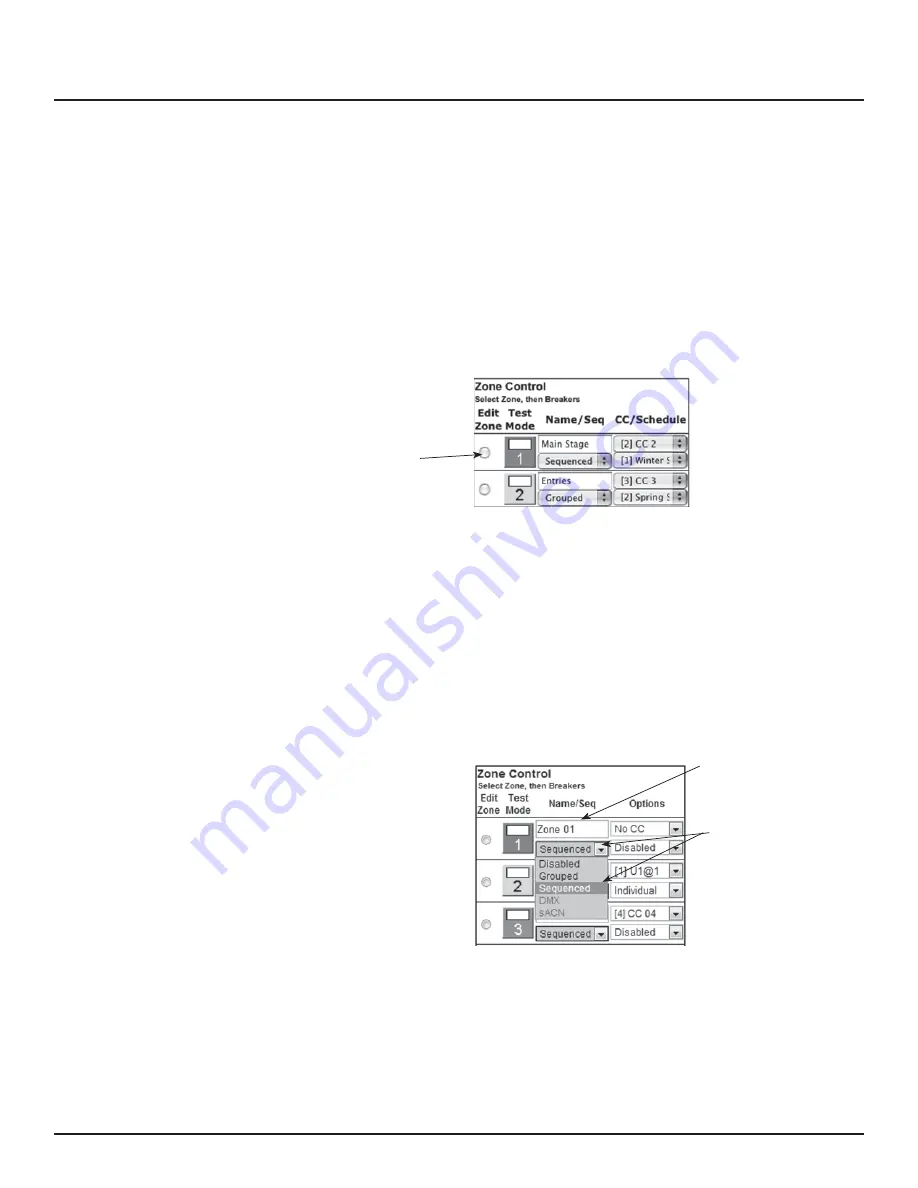

2. Name the Zone. (Figure 5-7)

3. Choose Grouped, Sequenced, DMX or sACN operation.

Note: DMX and sACN may not be used within the same

NPAC (Figure 5-7)

Figure 5-7

Name the

Zone

Choose operation

type from the

dropdown

4. If using DMX or sACN operation, select the address

set (Figure 5-8) or universe (Figure 5-9) from the

ZONE SETUP

Relays can be controlled individually or arranged into

zones. Relays in zones can be toggled at 25 ms intervals

(Grouped Operation), at variable intervals (Sequenced

Operation), or via DMX or sACN.

To setup a Zone follow these steps:

1. Choose which zone you would like to edit. (Figure

5-6)

Figure 5-6

Select

to Edit