Page 16 / June 2022

Installation, Operation and Maintenance Instructions

Weather-proof louvre, horizontal,

WSG-H3 for flat roof

Depending on the degree of soiling, clean the louvre at

regular intervals to remove leaves and similar deposits.

WSGs may be cleaned using compressed air, leaf blowers

or brushes. Make sure that as few solid particles (leaves,

twigs, etc.) pass through the top mesh grids. During clean-

ing work, it is absolutely forbidden to walk on the blades.

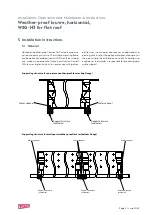

With very large and poorly accessible WSG-H3, we recom-

mend covering the louvre with a wooden board or similar.

Please make sure that the wooden board is long enough

and contacts the louvre frame on both sides and does not

rest on the blades. The wooden board can be positioned

so that it can be walked on during cleaning work. Suitable

safety measures must be taken to safeguard the cleaning

personnel (e.g. fall protection). This is the responsibility of

the operator.

ATEX:

Compliance is mandatory with all relevant inter-

national and national standards and regulations for Ex

zones.

These installation, operation and maintenance instruc-

tions are not a binding installation document for horizon-

tal weather-proof louvres and mounting frames. However,

possible flat roof connection examples are published

based on conventional flat roof structures.

The specifications contained in this document were com-

piled to the best of our knowledge based on current

knowledge and experience. LUCOMA reserves the right

to make changes at any time to match the current state

of production practice. These planning documents make

no claim to completeness. No legally binding obligation

can therefore be derived from them. Compliance is man-

datory with the local construction laws, standards and

regulations for design, component dimensioning, material

selection, laying, and governing heat, moisture, noise and

fire protection.

7 Maintenance

8 Exemption from liability

Safety checkpoint

– Ring screws are tightened firmly and aligned correctly

(avoid lateral pull)

– Ring screws are undamaged (corrosion, deformation, etc.)

– The slings have sufficient load bearing capacity and

they are undamaged

– The slings cannot come loose on their own from the at-

tachment point

– Additional restraints to secure the load are present

– Load must never be suspended over people

– The executing employee has received the needed training

These safety checkpoints are intended as guidance, and

they are not exhaustive. Regarding the safety regulations,

the local requirements must be observed. Lucoma AG

does not accept any liability for the load-bearing capacity

of the screws and the consequences of improper handling.

We recommend securing the loads additionally.