Finalizing the Installation

(for qualified installers only)

17

© Travis Industries

6/27/2019 - 1500

864 31K CF Aust

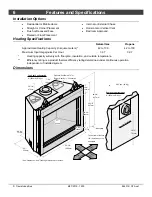

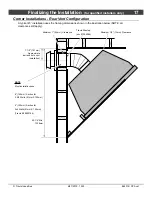

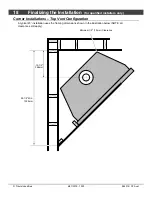

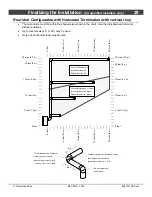

Corner Installations - Rear Vent Configuration

A typical 45° installation uses the framing dimensions shown in the illustration below (NOTE: all

clearances still apply).

7-1/2" (191mm)

Approximate

(varies due to vent

installation)

Minimum 1/2" (13mm) Clearance

NOTE:

Most installations use:

6" (152mm) Section for

2 X 6 Walls (51mm X 152mm)

4" (102mm) Section for

2x4 Walls (51mm X 102mm)

(Travis # 98900166)

Minimum 1" (25mm) Clearance

Travis Firestop

(sku 93006094)

52-1/4" Min.

1328mm