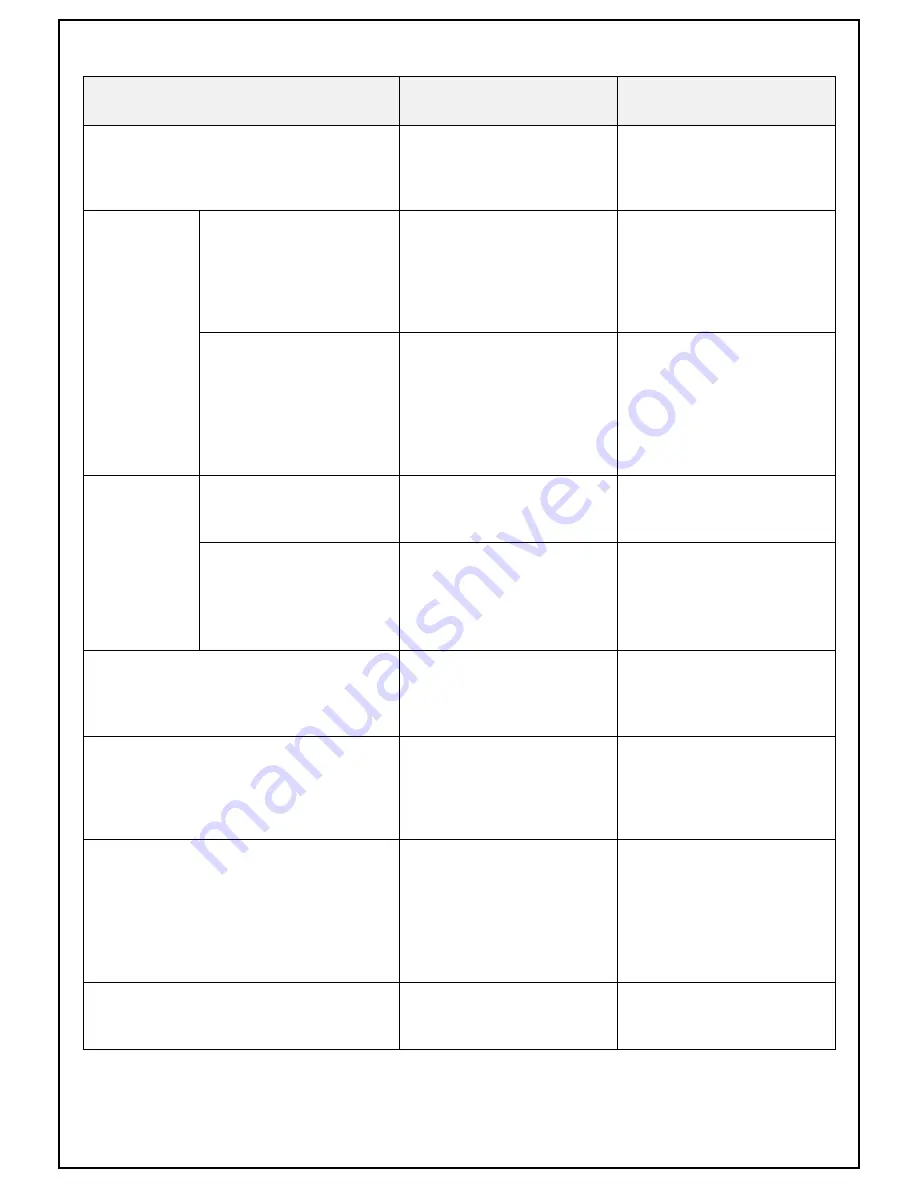

■ TROUBLESHOOTING

√ If all recommended action have been checked and the problem persists, please contact our service

center

SYMPTOMS

REASON

RECOMMENDED ACTION

Cooling fan does not run when the power switch is

turn on.

․

No input voltage

․

Fuse (5A) is blown

․

Power switch broke down

․

Cooling fan broke down

․

Verify input voltage

․

Replace Fuse (5A)

․

Replace Power switch

․

Replace Cooling fan

Welding wire

does not go out

from wire feeder

Welding wire does not go out

when pressing the inching switch

of wire feeder

․

Fuse (15A) is blown

․

Wire feeding cable does not

connect perfectly

․

Motor of wire feeder broke down

․

Control PCB broke down

․

Replace Fuse (15A)

․

Reconnect Wire feeding cable of

torch

․

Replace Motor of wire feeder

․

Replace Control PCB

Wire feeding has no problem

when pressing the inching

switch, but Welding wire does

not go out from wire feeder

when pressing the torch switch

of torch

․

Torch switch connector does not

connect perfectly

․

Torch switch broke down

․

Control PCB broke down

․

Reconnect Torch switch connector

․

Replace Torch

․

Replace Control PCB

Gas does not

flow from torch

Gas does not flow from torch

when the GAS CHECK switch is

"GAS CHECK" position

․

Close the valve of gas tank

․

Gas check switch broke down

․

Open the valve of gas tank

․

Replace Gas check switch

Gas does not flow from torch

when pressing the torch switch

․

Torch switch connector does not

connect perfectly

․

Torch switch broke down

․

Control PCB broke down

․

Reconnect Torch switch connector

․

Replace Torch

․

Replace Control PCB

Gas flows continuous at "WELDING" position of GAS

CHECK switch

․

GAS CHECK switch broke down

․

Torch broke down

․

Control PCB broke down

․

Replace GAS CHECK switch

․

Replace Torch

․

Replace Control PCB

It does not adjust the welding voltage and current on

the wire feeder

․

Remote control connectors of

wire feeder does not connect

perfectly

․

Volume broke down

․

Control PCB broke down

․

Reconnect Remote control

connectors of wire feeder

․

Replace Volume

․

Replace Control PCB

Arc does not started

․

Torch cable is broke

․

Torch switch connector does not

connect perfectly

․

Work cable does not connect

perfectly

․

Torch broke down

․

Control PCB broke down

․

Repair Torch cable

․

Reconnect Torch switch connector

․

Reconnect Work cable

․

Replace Torch

․

Replace Control PCB

Crater does not work

․

Crater select switch broke down

․

Control PCB broke down

․

Contact our service center