Seite 8

9. Air supply for combustion WITH dependence on indoor air

(open-flued appliance)

9. Air supply for combustion WITH dependence on indoor air

(open-flued appliance)

Air supply for combustion via the room where the appliance is

located

the air required for combustion is drawn from the room where the appliance

is located. the room must be periodically ventilated, especially in well sealed

buildings.

therefore provide sufficient changes of air in the room where the appliance is

located. For rooms exceeding a volume of 50 m3, we recommend exchanging

1.5 times the volume of air per hour. For smaller rooms the rate of air exchange

should be increased.

If there are additional heating appliances in the same room, make sure that

the air inlets can supply sufficient air for combustion for the operation of all

appliances.

Only if certain conditions are fulfilled it is permissible to operate open-flued

fireplaces in combination with ventilation systems etc. For further information

seek the advice of the manufacturer of your ventilation system.

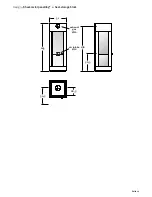

Air supply for combustion via the room where the appliance is

located

(Figure 5)

•

the air for combustion is pre-heated.

•

It is necessary to ventilate the room at regular intervals or to provide a per-

manent opening for ventilation to the outside.

outdoor air supply for combustion

(Figure 6)

•

the air for combustion is only slightly pre-heated!

•

Max. length 4 m with 3 bends.

Negative pressures in the room where the ap-

pliance is located (e.g. through ventilation sys-

tems, extractor hoods, etc.) may impair the func-

tioning of the fireplace and its safety system and

are therefore not permissible.

Please consult the local qualified chimney

sweep and observe the local fire protection laws

as well as the standards DIN 18896 (technical

standards for the installation and the operation

of fireplaces for solid fuels).

Negative pressures in the room where the ap-

pliance is located (e.g. through ventilation sys-

tems, extractor hoods, etc.) may impair the func-

tioning of the fireplace and its safety system and

are therefore not permissible.

Please consult the local qualified chimney

sweep and observe the local fire protection laws

as well as the standards DIN 18896 (technical

standards for the installation and the operation

of fireplaces for solid fuels).

Operate extractor hoods only with re-circulated

air operation!

With ducted extractor hoods, an adequate sup-

ply of air must be ensured by means of separate

safety equipment (e.g. contact switches on the

windows, negative-pressure monitoring).

Operate extractor hoods only with re-circulated

air operation!

With ducted extractor hoods, an adequate sup-

ply of air must be ensured by means of separate

safety equipment (e.g. contact switches on the

windows, negative-pressure monitoring).

Figure 5

Figure 6

air

intake

air

intake

exhaust gas

exhaust gas

convection air

outlet

convection air

outlet

air intake / convec-

tion air outlet

convection air

outlet