Seite 11

13. Customer-supplied panelling

13. Customer-supplied panelling

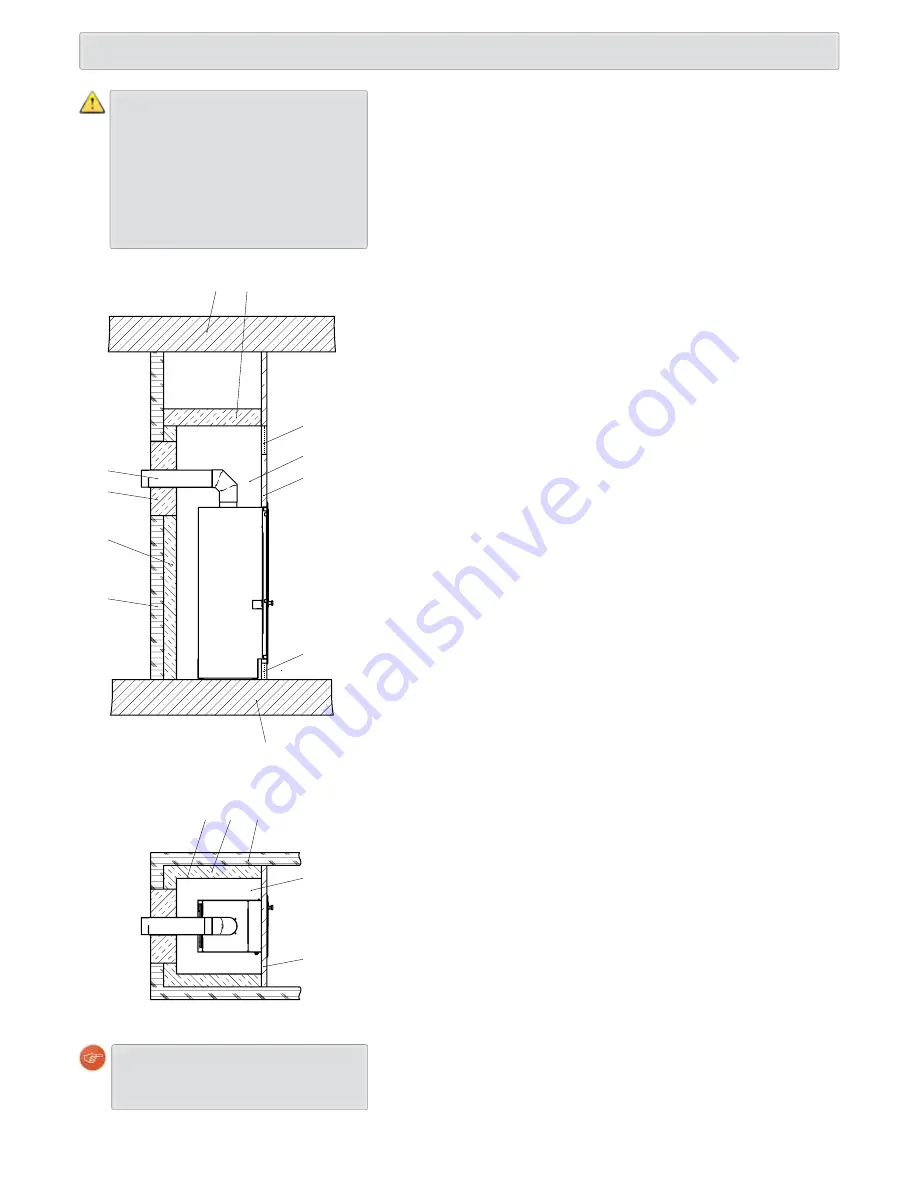

Figure 12

Under no circumstances does Lohberger assume

liability for the installation of the appliance. The

HVAC installer conducting the inspections for fire

safety shall bear the responsibility.

Under no circumstances does Lohberger assume

liability for the installation of the appliance. The

HVAC installer conducting the inspections for fire

safety shall bear the responsibility.

installation instructions

If the appliance is installed in front of or next to a wall requiring protection,

please observe the following installation instructions

Figure 12

:

1

Convection casing

(e.g. galvanized sheet steel)

2

Thermal insulation

: Isolrath 1000, 9 cm thick

3

Walls to be protected

: inflammable walls, load-bearing walls made of

reinforced concrete, etc.

4

Convection air space

, clearance between convection casing and heating

appliance

5

Customer‘s external panelling

made from incombustible building

materials.

6

Ceiling

7

Thermal insulation

: Isolrath 1000, 12 cm thick

8

Flue gas pipe

9

Thermal insulation wall duct

Flue gas pipe: Isolrath 1000, 20 cm thick

10

Flue air grille

, hot air outlet

11

Supply air grille

, cold air inlet

Thermal insulation (2/7/9)

the thermal insulation must be without joints and with overlap.

Insulating material in compliance with building material class a1 according to

DIn 4102, part 1, must be used. the type testing was carried out with the insu-

lation material Isolrath 1000 produced by the rath company. alternatively, other

approved insulation materials (DIBt-approval) with identical technical data or

thermal conductivity can be used.

Maintain a minimum thickness of insulation materials as specified:

adjoining wall 9 cm, ceiling 12 cm, wall duct flue gas pipe 20 cm

Convection air space (4)

the appliance must be surrounded by a convection air space; the distance

between the convection air casing and the heating appliance must be at least

15 cm. the cold room air enters from below via the supply air grille (

11

), heats

up and is fed back at the top through the flue gas grille into the room where

the appliance is installed.

Customer‘s external panelling (5)

the external panelling provided by the customer serves to emit the heat to

the room where the appliance is installed and must consist of incombustible

building materials (building material class a1).

the panelling must be stable and self-supporting; that means it must not have

a fixed connection to the appliance. the distance between panelling and appli-

ance should be permanently elastic (stretching / sealing strip).

Convection air openings (10+11)

the required free cross section of the supply air opening or of the exhaust air

opening is specified in the technical data. Make sure that the convection air

openings cannot be closed and locate them in such a way that they cannot be

obstructed. an obstruction could lead to heat build-up and as a consequence

to overheating the appliance, chimney or adjoining parts / furniture. Maintain

a minimum distance of 52 cm between the exhaust air grille and ceilings. the

exhaust air grille must be located at the highest point of the convection air

casing to prevent heat build-up in the panelling.

1

1 2 3

6

6

7

10

11

5

5

4

3

9

8

2

Caution – fire risk:

Please make sure to ob-

serve the fire regulations such as those for

thermal insulation and dimensions of air inlet

grills.

Risk of overheating due to heat build-up.

The appliance must not be installed without

grilles for supply air and exhaust air. In the

event of insufficient convection air, fuel stored

in the firewood compartment may ignite.

Caution – fire risk:

Please make sure to ob-

serve the fire regulations such as those for

thermal insulation and dimensions of air inlet

grills.

Risk of overheating due to heat build-up.

The appliance must not be installed without

grilles for supply air and exhaust air. In the

event of insufficient convection air, fuel stored

in the firewood compartment may ignite.