12

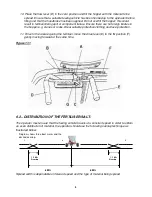

6.6 - LDS120DS

–

CALIBRATION (SALT)

The

Logic LDS120DS

is capable of spreading dry white bagged de-icing salt only.

All materials will vary slightly, depending on density and moisture, etc, even in bags, the same

batch can vary.

The following steps are intended as a guide only, and it is highly recommended that simple test

runs are carried out in the filling area before setting out, to check that the spreading quantity

and pattern are satisfactory.

The main controlling factor is forward speed, which dictates the spreading width. The

application rate will then be controlled by the feed gate setting.

The recommended

minimum

working forward speed is

3 mph

(5 kph). This would be used in

confined spaces, or where a minimum spreading width is required. At this speed the spreading

width will be approx. 8mtrs. Recommended

maximum working

speed is

12 mph

(19 kph)

which will result in a spreading width of approx 12mtrs suitable for car parks and roads, etc.

The feed gate setting at the front of the hopper controls the material flow and therefore the

application rate (grams per sq metre). Our recommendation would be to use setting 6 for

spreading salt; the aperture needs to be open enough to prevent the salt bridging in the hopper.

For transporting max / min operating speeds see page 4.

CALIBRATION STAGES

1.

Decide what spread width

is required in relation to a safe working speed.

2.

Select the feed gate setting

to achieve the desired application rate.

This will depend on trials carried out with materials to be spread at the time.

3.

Check the accuracy of the settings, try a few trial runs over a clean area of concrete or

road surface, at the correct forward speed. Check the spread width, which may vary due

to bouncing material if it is very dry.

Check the application rate by visually looking at your test run and ensure a suitable

amount of salt is spread evenly. To change the application rate alter the forward speed

or aperture setting accordingly to ensure the correct amount of salt you require is applied

4.

Write down results for future reference in the table provided (See next page).