11

4

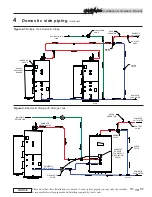

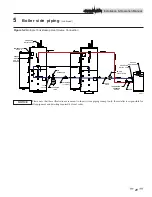

Domestic side piping

Basic domestic piping

Figure 4-4 on page 17 shows typical domestic water and space

heating piping for a Strato-Therm+ tank. The stainless steel coil

requires properly sized piping and a properly sized pump to

maintain adequate domestic hot water delivery. Refer to Tables

4D and 4E on page 14 and 15 for domestic coil pressure drop.

The functions of the components shown are as follows:

a. Shut-off valves (recommended) - Used to isolate the

appliance for servicing.

b. Backflow Preventer (required by some codes) - Used to

prevent water from backing out of the indirect coil and

into the main potable water supply in the event that inlet

water pressure drops.

c. Expansion Tank (required for thermal expansion) - Tank

absorbs the increased volume caused by heating water.

Use an expansion tank designed for use on domestic water

systems. Refer to the expansion tank manufacturer’s

instructions for proper sizing and use.

NOTICE

If an expansion tank is used, do not put any

valves between the expansion tank and tank

inlet.

d. Shock Arrestor (required by some codes) - Used to allow

water to accelerate or decelerate without a sudden change in

pressure.

NOTICE

Be sure to field-install plugs or caps on any

tank tappings that are not in use.

e. Circulation Pump (recommended) - Used to circulate

and maintain hot water within the piping system.

f. Check Valve (required by some codes) - Used to allow

water to flow in only one direction, preventing back-flow.

g. Drain (required) - Used to drain the tank for inspection or

servicing.

h. Mixing valve (required) - Used to mix hot water with cold

water to ensure constant, safe outlet temperatures.

i. Unions (optional) - Used to disconnect the tank in the

unlikely event that this is necessary for service.

Because hot water is always circulating in the hot water branch,

the entire branch should be insulated to prevent excessive heat

loss.

When a hot water recirculation system is used there are two

piping arrangements that can be applied to the Strato-Therm+.

The first arrangement is for use in systems with up to 2 gal/

min circulation and requires the purchase of a recirculation

lance assembly (FIG. 4-5, page 18). The second arrangement

is for use in systems with greater than 2 gal/min circulation

that require higher performance and temperature (FIG. 4-6,

page 18).

Domestic water piping for distant fixtures

In some cases the furthest fixture may be located far from the

tank. This may result in an unacceptable delay before hot water

reaches these distant fixtures. Even if all the fixtures are located

relatively close to the tank, it may be desired that hot water be

instantly available to all fixtures.

To prevent delays, return circulation piping with a check valve

that allows flow to the domestic hot water outlet. This should

be installed on each branch circuit at the farthest fixture or

device, so that hot water is supplied upon demand. Traditional

recirculation piping is illustrated in FIG. 4-1, page 12.

Installation & Operation Manual