20

L o c h i n v a r

D E S I G N E R

’

S

G U I D E

Lochinvar

secondary pump(s). When piped correctly,

the secondary pump helps to prevent flow

through the boiler(s) when they are not firing.

Use of a primary/secondary system will

eliminate the need for a System or Boiler

Bypass. (Figure 19) depicts one example of

primary/secondary piping.

Water Flow Switch

Due to the low water content (between 1 and 6

gallons) of the Copper Finned Tube heat

exchanger, a flow switch is factory installed as

a low water cutoff device on all models. The

flow switch is installed in the outlet piping of the

boiler and wired into the ignition system. A

minimum of 20 GPM is required to make the

flow switch. Per ASME CSD1 and in most

localities, a flow switch is accepted as a low

water cutoff for boilers requiring forced

circulation. (See CSD1 CW-210) It is prudent to

verify preference with the local code official.

A specially sealed flow switch and conduit are

furnished for outdoor installations.

Low Water Cutoff

If this boiler is installed above radiation level, a

low water cutoff device

must

be installed at

the time of boiler installation (option, available

from factory).

Relief Valve

This boiler is supplied with a pressure relief

valve sized in accordance with

ASME Boiler and

Pressure Vessel Code, Section IV

“Heating Boilers”.

Low Flow Systems

When the system flow rate is less than the

minimum flow required for proper boiler

operation, the boiler should be installed with a

primary/secondary piping system.

This will allow the installation of a secondary-

circulating pump sized specifically to provide a

higher flow rate through the boiler and the

secondary loop piping to ensure proper

operation. See “Primary/Secondary Piping”

for installation and piping requirements.

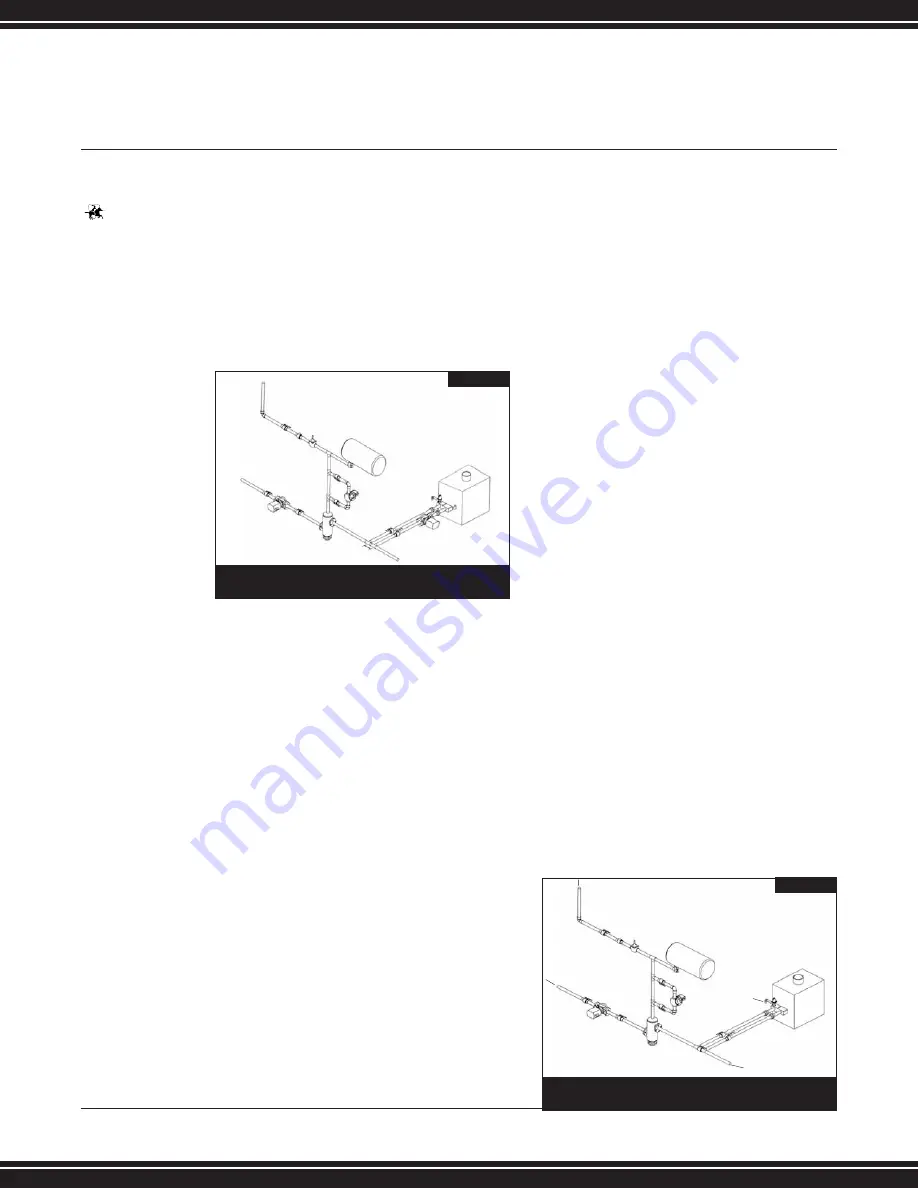

High Flow Systems

When the flow rate of the system exceeds the

maximum allowable flow rate through the

boiler (Table L), boiler bypass piping should be

installed. The bypass will divert the required

portion of the system flow to the boiler and

bypass excess system flow. This will effectively

reduce boiler flow to an acceptable rate and

increase system flow. The bypass piping should

be sized equal to the system piping. Figure 18

depicts the proper piping arrangement for the

boiler bypass.

(FIG. 20) HIGH FLOW SYSTEM PIPING

HEATING SUPPLY

LOOP

TO FLOOR

DRAIN

MAKE-UP WATER

HEATING RETURN LOOP

LIT0471

IMPORTANT:

Operation

of this boiler

on low

temperature

systems

requires special

piping to insure

correct

operation.

Consult low

temperature

system section

for piping

details.

(FIG. 19) PRIMARY/SECONDARY SYSTEM PIPING

HEATING SUPPLY

LOOP

*12” MAX

TO FLOOR

DRAIN

MAKE-UP WATER

LIT0476

HEATING RETURN LOOP

Summary of Contents for Copper-Fin II CX401

Page 31: ......