www.lmicorporation.com 13

Press and hold PRESET

until the underscore is

under the one.

8.4

ZERO/ABS – MEASUREMENT MODES

The digital indicator has two modes to take measurements. ZERO

Mode (also known as INCremental Mode) is used to take

measurements from a value of zero. ABS or Absolute Mode is used to

take measurements from a Preset value.

To enter ZERO Mode, press and release the ZERO/ABS button. The

LCD will display all zeros.

To enter ABS Mode, press and release the PRESET

button. Press and release the PRESET button will take

the current position of the spindle and assign it your

Preset value. The ABS icon will appear in the bottom

left corner of the LCD. The default Preset value is

10.0mm. To change the Preset see section 8.5.

If you switch to ZERO Mode and want to return to

your last Preset stem position in ABS Mode press and

hold the ZERO/ABS button for 3 seconds.

NOTE:

Tolerance Mode can be used with ZERO Mode and ABS Mode

8.5

SETTING THE PRESET VALUE

To change the PRESET value, press and hold the PRESET button for 3 seconds. The previous value

will be displayed. Press and hold the PRESET button to select the digit you want to change. Press

and release the PRESET button to change the value. When finished, press and hold the PRESET

button until none of the digits are underscored and SET is flashing. Press and release the PRESET

button and the value will be set. Note that if you set the PRESET value to the max (9999.99 mm or

99.9995 in) and the measurement exceeds those values, then the LCD will display “Err-OL”,

meaning a character overload.

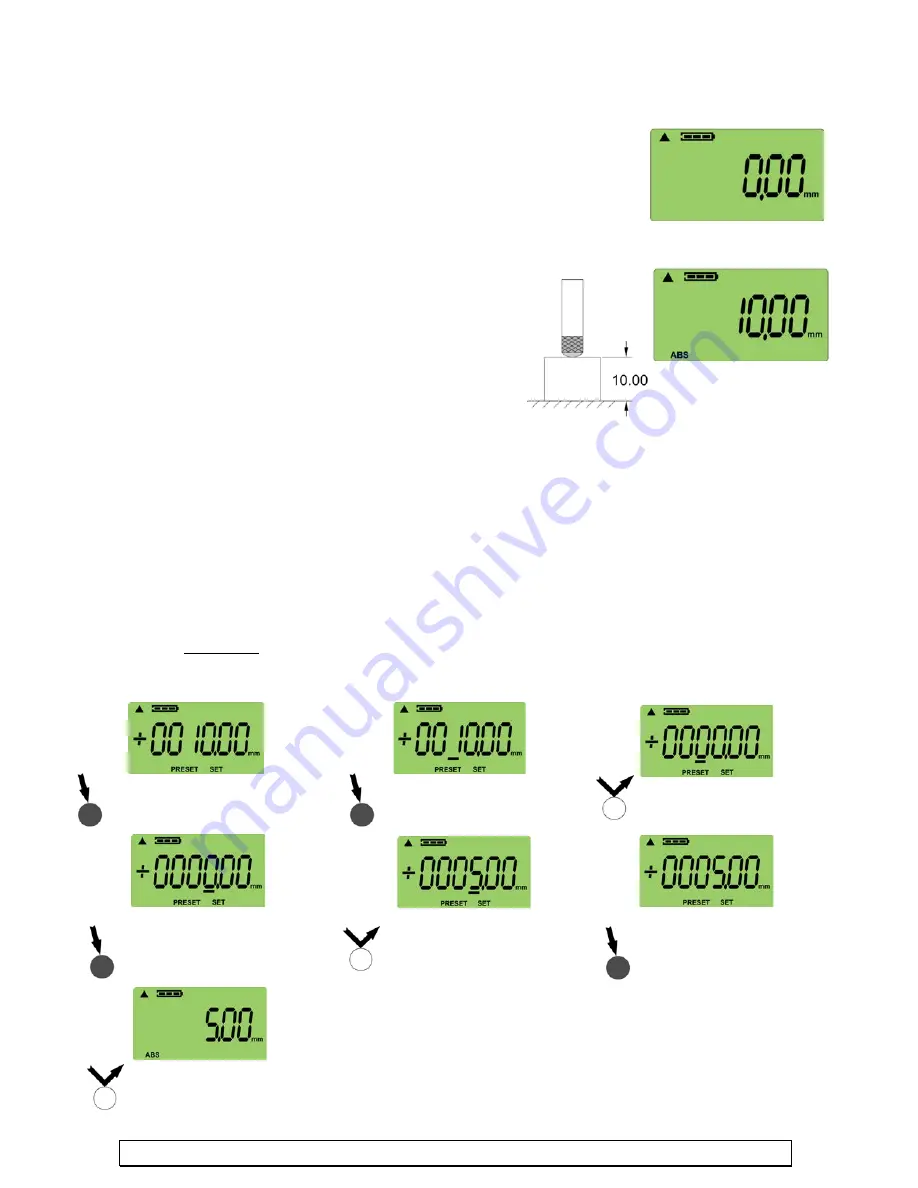

EXAMPLE:

For this example, we are going to change the default PRESET value of +10.00 to the new value of +5.00mm.

Press and hold PRESET for 3

seconds. The previous value

will display. SET will flash

Press and hold PRESET

until the underscore is

under the fourth digit.

Press and release PRESET

until the fourth digit

becomes a five.

Press and hold PRESET

until the underscore is

gone and SET starts to

flash.

Press and release

PRESET. The new

value is now 5.00mm.

Press and release

PRESET until the digit

becomes a zero.

ZERO Mode

ABS Mode