Service

7. Service

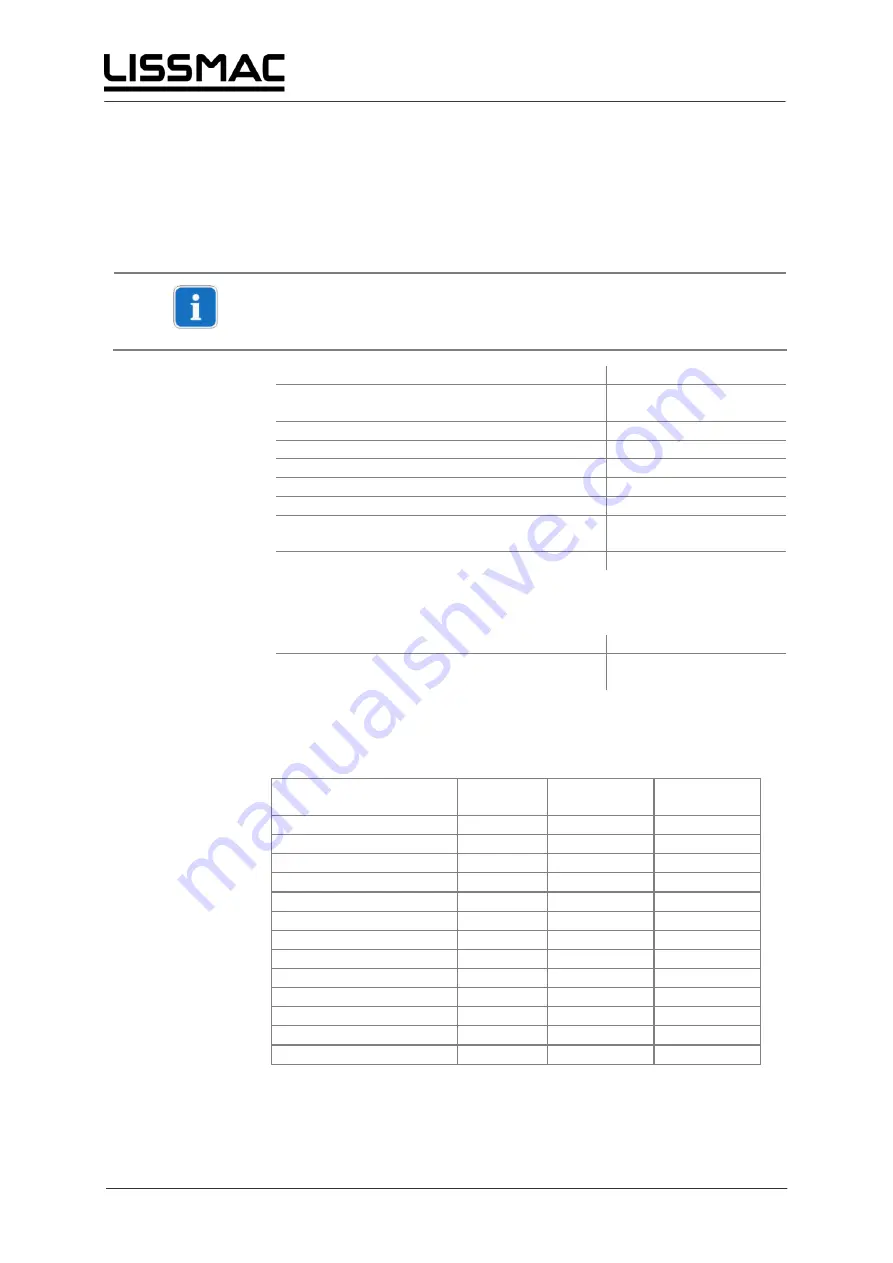

7.1. Service intervals

The following service work should be performed regularly in the specified

intervals (8 h). The intervals are shortened corresponding to multiple-shift

operation.

Service work

Interval

Clean the interior space of the machine and the slag

/ slag capture boxes

daily/once per shift

Clean magnets

daily/once per shift

Replace filter pads

weekly

Rotate the power-pin belts

after 500 operating hours

Change power-pin belts

after 1000 operating hours

Check drive belts and deflection rollers for wear

daily/once per shift

Lubricating the spindle threads for the height

adjustment

monthly

Tensioning and lubricating the chains

quarterly

7.2. Maintenance material

Consumables Designation

Roller bearing lubricant – spindle axes, etc.

Multi-purpose grease

(BP Energrease LS3)

7.3. Tightening torques

All the torques specified here assume steel screw connections.

hexagon head screw /

nut

8.8 10.9 12.9

M4 2,5

4

4,5

M5 5

7,5

9

M6 9

13

15

M7 14

20

25

M8 22

30

35

M10 45

65

75

M12 75

105

125

M14 115

170

200

M16 180

260

310

M18 260

370

430

M20 360

520

600

M22 490

700

820

M24 620

890

1040

Deslagging machine SBM-M 1000/1500 D2

45